Principal focus type refracting-reflecting optical system

An optical system and beam technology, applied in the field of optical systems, can solve the problems of difficult processing and detection of large-diameter high-order aspheric surfaces, complex correction groups, difficult manufacturing and processing, etc., and achieve good optical processing performance, convenient processing and inspection, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

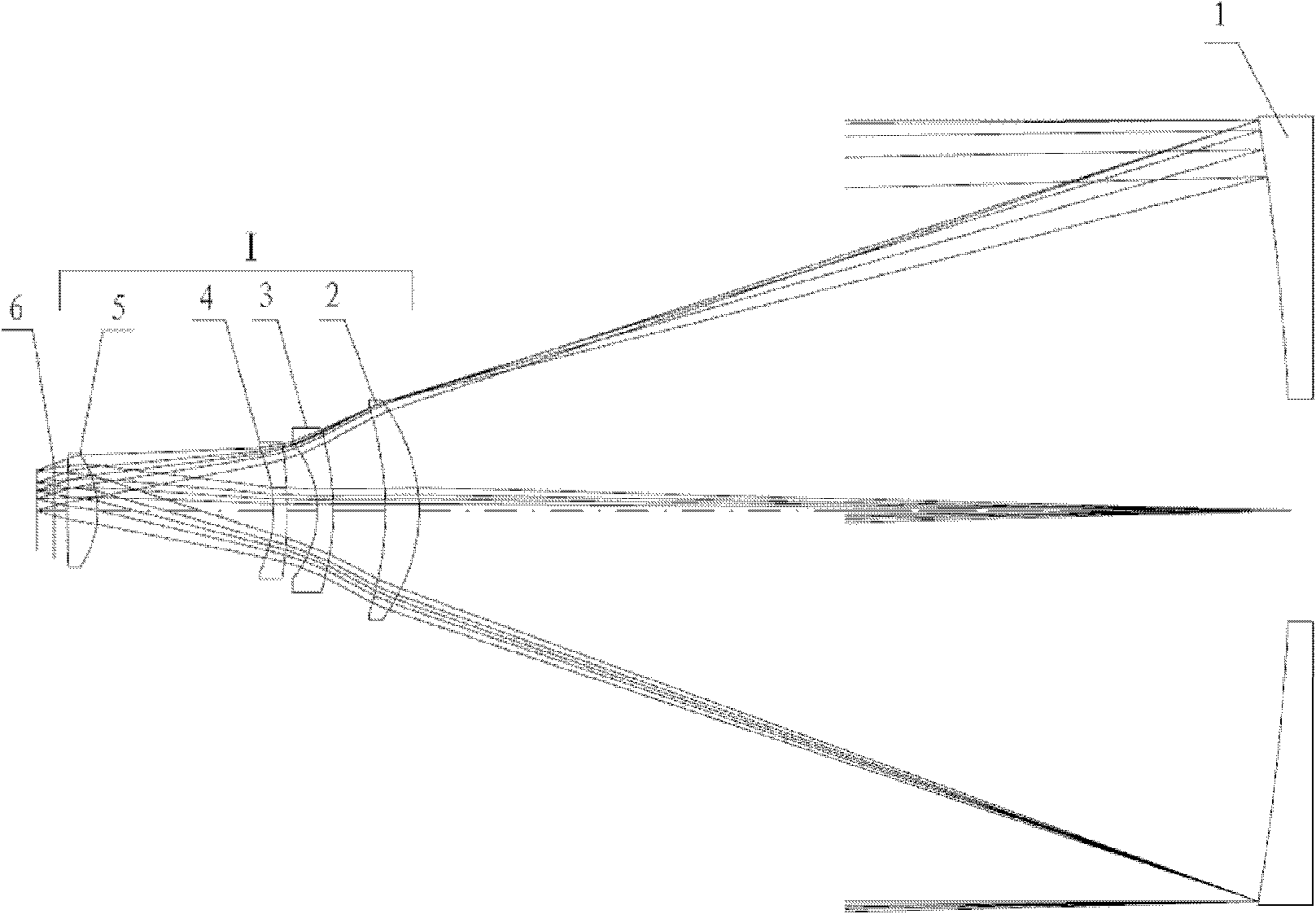

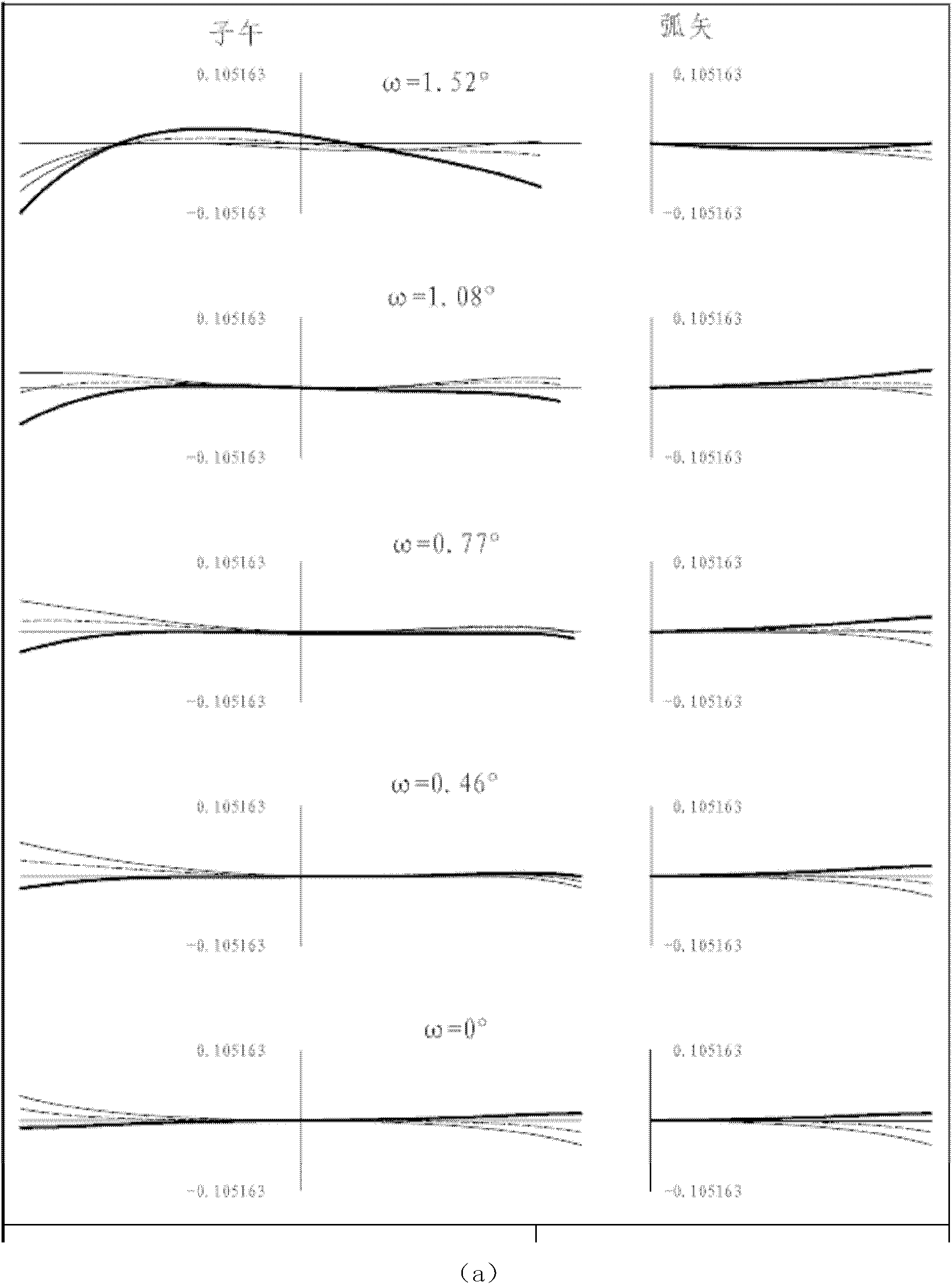

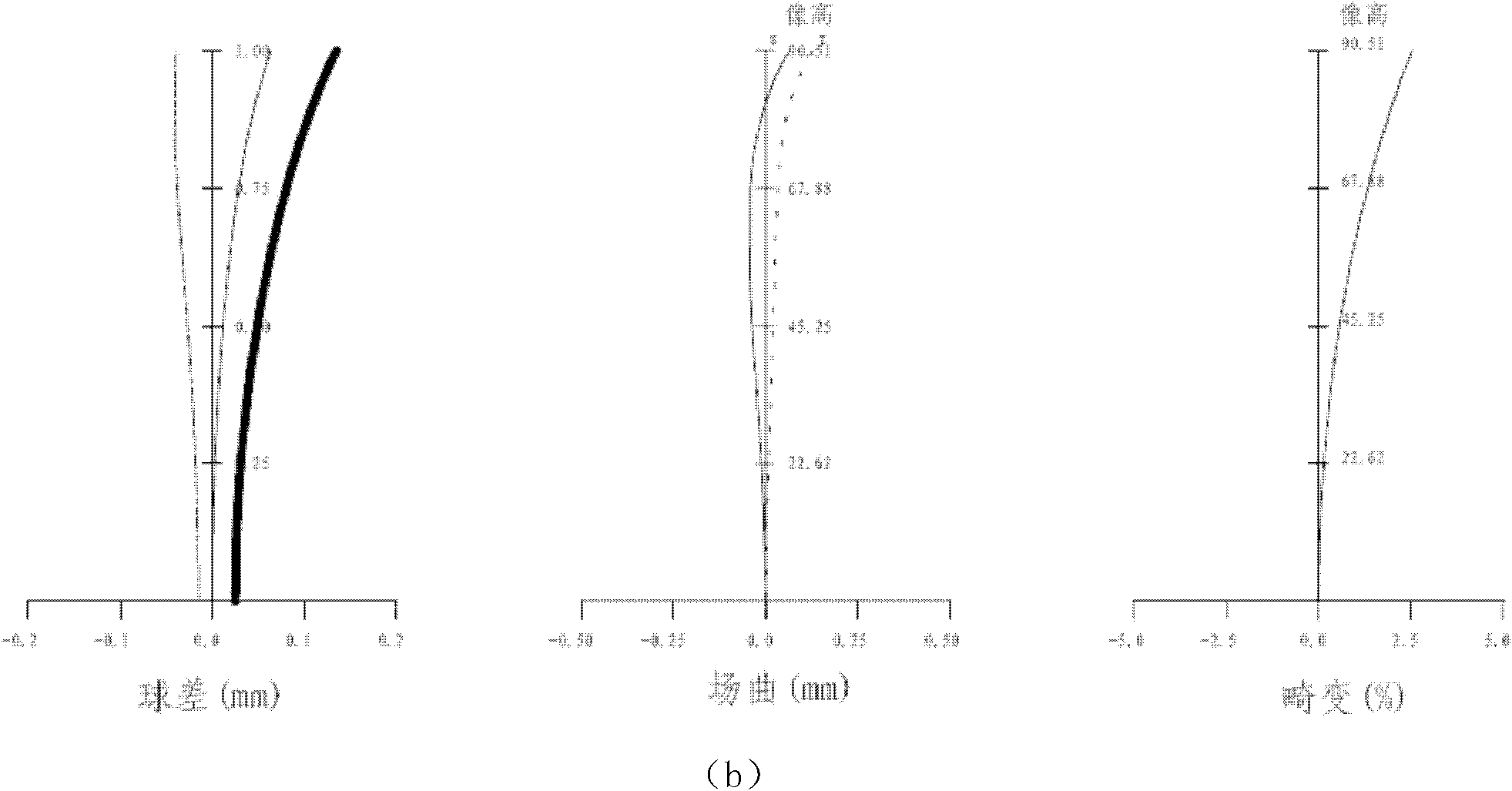

[0015] see figure 1 , the main focus type catadioptric optical telescope of the present invention comprises a parabolic primary mirror 1 and a correction group 1 and a focal plane shutter 6, wherein the first lens 2, the second lens 3, the third lens 4 and the fourth lens 5 are formed The correction group I is placed on the reflected optical path of the main mirror 1, and the correction group I mainly corrects the aberration of the peripheral field of view of the main mirror 1, thereby increasing the effective field of view. Among them, the characteristics and positional relationship of the four lenses of the correction group I according to the optical path are as follows: the first lens 2 is a meniscus lens with a positive refractive power and a convex surface facing the main mirror 1, and the second lens 3 is a negative refractive power and a convex surface. A meniscus lens facing the main mirror 1 , the third lens 4 is a meniscus lens with a negative refractive power and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com