Method and device capable of obtaining ultraviolet light protection layer on surface of development roller

A technology of ultraviolet light and developing roller, which is applied in optics, electric recording process applying charge pattern, equipment of electric recording process applying charge pattern, etc. , become dust impurities and other problems, to achieve the effect of improving process efficiency, saving energy consumption and prolonging printing life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

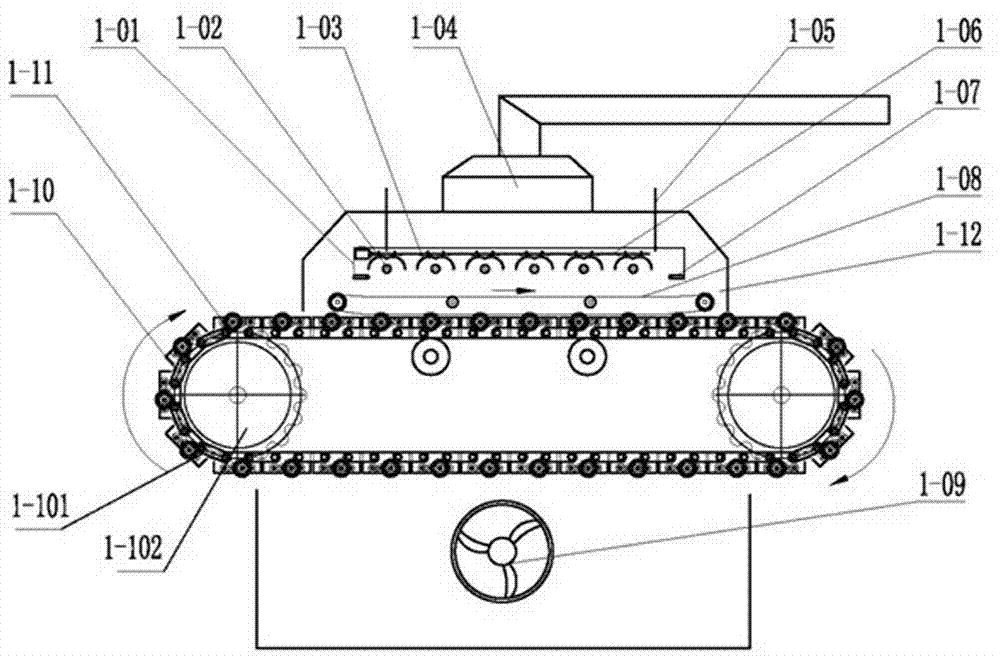

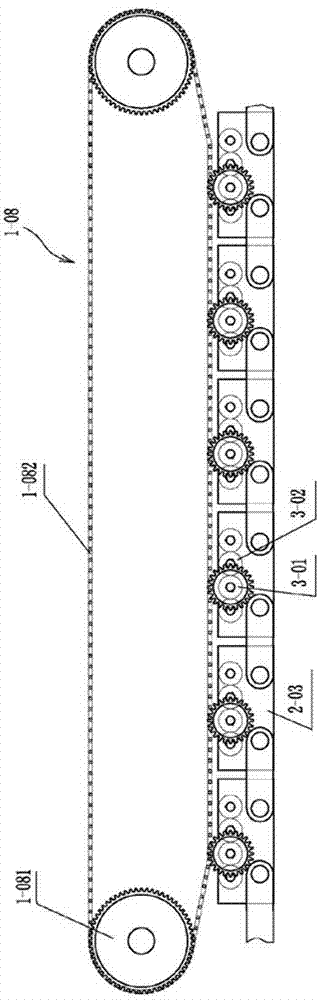

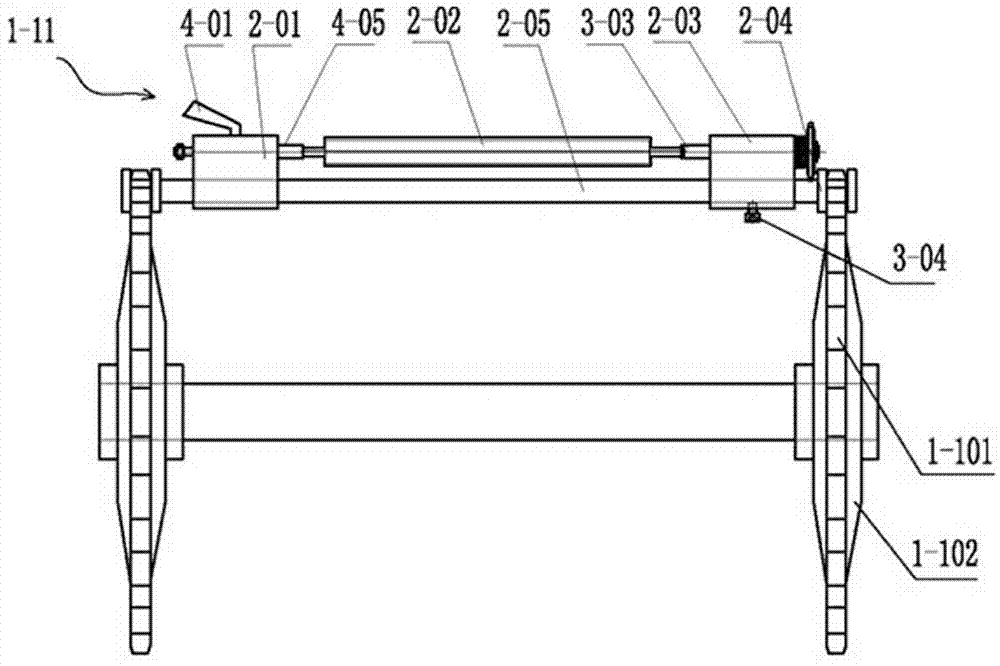

[0039] In order to achieve the purpose of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0040] Ultraviolet light surface quality change technology - referred to as UV (Ultrasonic-Violet) technology, is considered to be an environmentally friendly green technology, also known as 3E technology, namely energy saving (energy), environmental protection (environment), economy (economy). According to the different electromagnetic wavelengths of UV light, it has four functions: 1) UV light cures LCD sealing and frame sealing glue; 2) UV light exposure process; 3) UV light cleaning (sterilization); 4) UV UV light modification quality (ultraviolet light surface quality change). It is widely used in: printing (screen printing, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com