Method for simulating simulation splash in high speed impact

A simulation method, high-speed impact technology, applied in the field of high-speed impact simulation splash simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

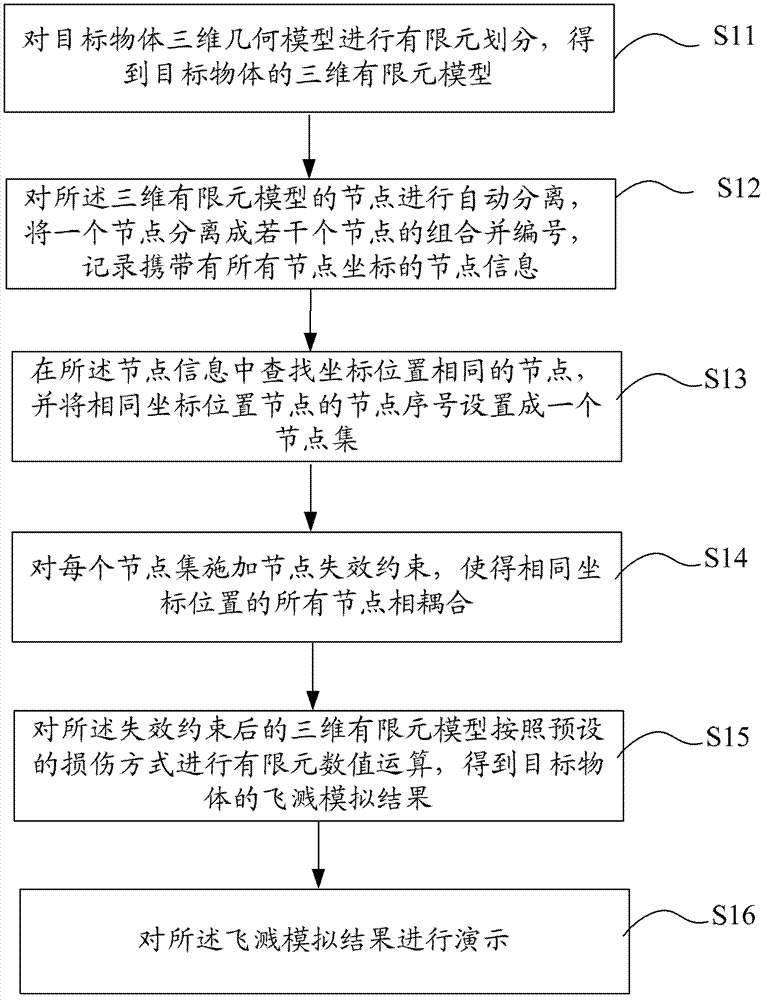

Method used

Image

Examples

Embodiment 1

[0066] In the embodiment of the present application, the target object is the human maxilla, simulating the splash effect after the human maxilla is penetrated by the steel ball.

[0067] First construct the 3D geometric model of the skull, and then use the finite element preprocessing software ANSA to divide the 3D geometric model of the skull into finite elements to obtain the 3D finite element model of the skull, as shown in Figure 7 As shown, it is an oblique view of the finite element model of the human skull, and the area shown at 100 in the figure is the maxilla, Figure 8 Posterior view of the finite element model for the human skull.

[0068] Then use Matlab software to Figure 7 In the area shown in 100, the nodes are automatically separated and coupled to prepare for the subsequent simulated impact. And after the automatic node separation and coupling, the finite element calculation software Ls-dyna is used to perform finite element numerical calculation on the c...

Embodiment 2

[0071] In the embodiment of the present application, the target object is a human mandible, simulating the splash effect after the human mandible is penetrated by a bullet.

[0072] Before simulating the human mandible being penetrated by bullets, first construct the 3D geometric model of the mandible, and then use the finite element pre-processing software ANSA to perform finite element division on the 3D geometric model of the skull to obtain the 3D finite element model of the mandible, as shown in Figure 10 Shown is the front view of the finite element model of the mandible, Figure 11 Posterior view of the finite element model for the mandible.

[0073] In the embodiment of this application, the finite element calculation software Ls-dyna is finally used to perform finite element numerical calculations on the three-dimensional finite element model after the failure constraint according to the preset damage mode, and obtain the splash simulation after the mandible is penet...

Embodiment 3

[0075] In the embodiment of the present application, a steel plate is selected as the target object to simulate the splash effect after the steel plate is penetrated by explosive explosion.

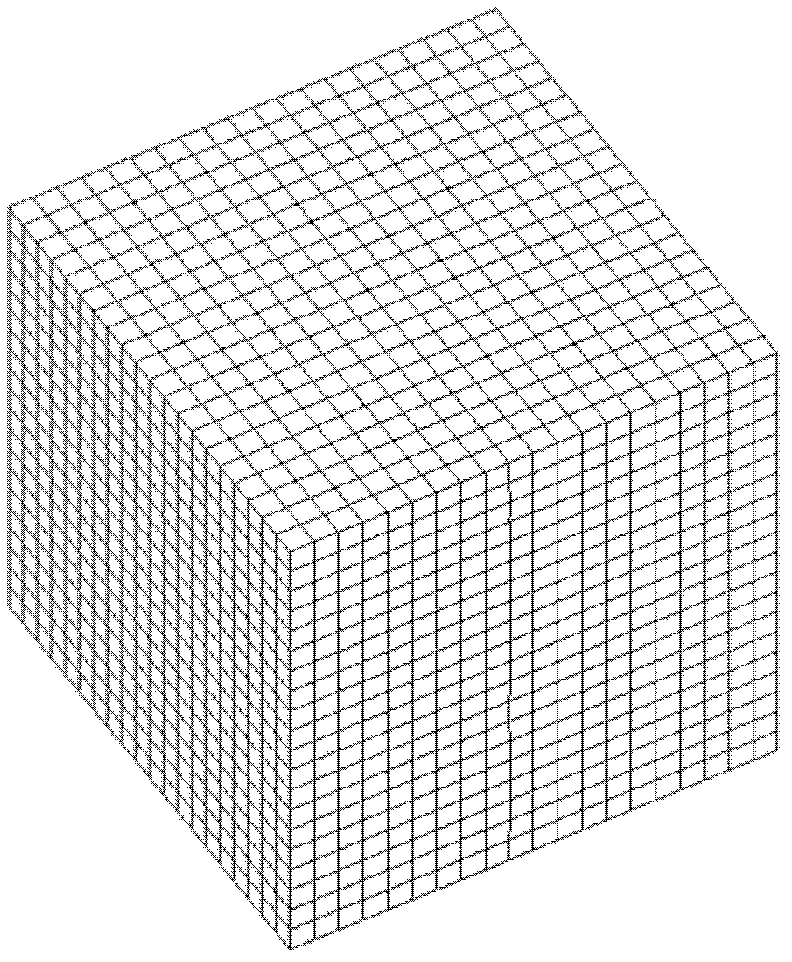

[0076] Same as the previous two embodiments, before the simulated steel plate is penetrated by the explosive explosion, it is also necessary to be able to construct a three-dimensional geometric model of the steel plate, such as Figure 13 Shown is the three-dimensional geometric model of the steel plate, 400 in the figure is the steel plate, and 500 is the explosive.

[0077] In the embodiment of this application, the finite element calculation software Ls-dyna is finally used to carry out finite element numerical calculations on the three-dimensional finite element model after the failure constraint according to the preset damage mode, and obtain the splash simulation of the steel plate penetrated by the explosive explosion results, such as Figure 14 Shown is the splash simulation res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com