A kind of braised beef seasoning paste and preparation method thereof

A technology for braised beef and seasoning paste, which is applied in the field of food processing, can solve the problems that the natural flavor of braised beef cannot be maintained for a long time, the fragrance retention time is short, and the simulation degree is not high, and the color and luster are attractive, the meat is rich and natural, and the taste is good. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

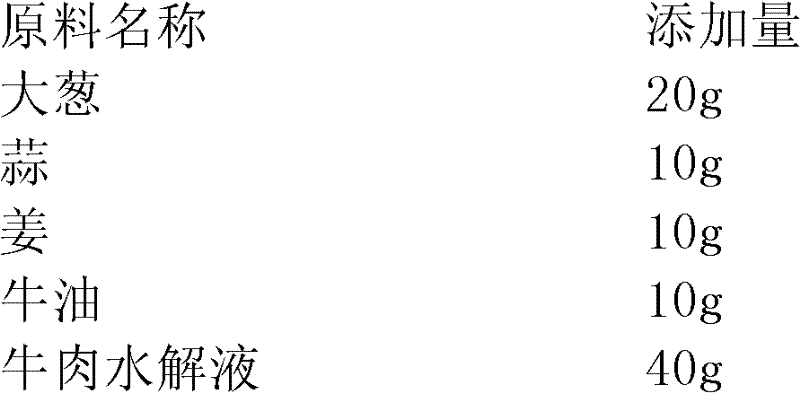

[0018] The raw materials and the addition amount of the braised beef seasoning paste are as follows:

[0019]

[0020]

[0021] Prepare the above-mentioned braised beef seasoning paste through the following steps:

[0022] Ground the fresh beef, added papain whose weight is 1.0% of the weight of the fresh beef, and hydrolyzed it at 60°C for 0.5 hour to obtain a beef hydrolyzate.

[0023] Take scallions, garlic, and ginger, remove the dried leaves, wash, chop, grind them through a colloid mill, put them in a reaction kettle, add water, butter, soybean oil, beef hydrolyzate, cinnamon powder, anise powder, and peppercorns after stirring Flour, grass fruit powder, soy sauce, glucose, anise oleoresin, cinnamon oleoresin, seal the reaction kettle, stir and heat to 125°C, and keep it warm for 100 minutes; then stop heating, cool to 60°C, add BHA, modified starch, malt Dextrin, after stirring for 20 minutes, passed through a colloid mill, and passed through a 40-mesh sieve to o...

Embodiment 2

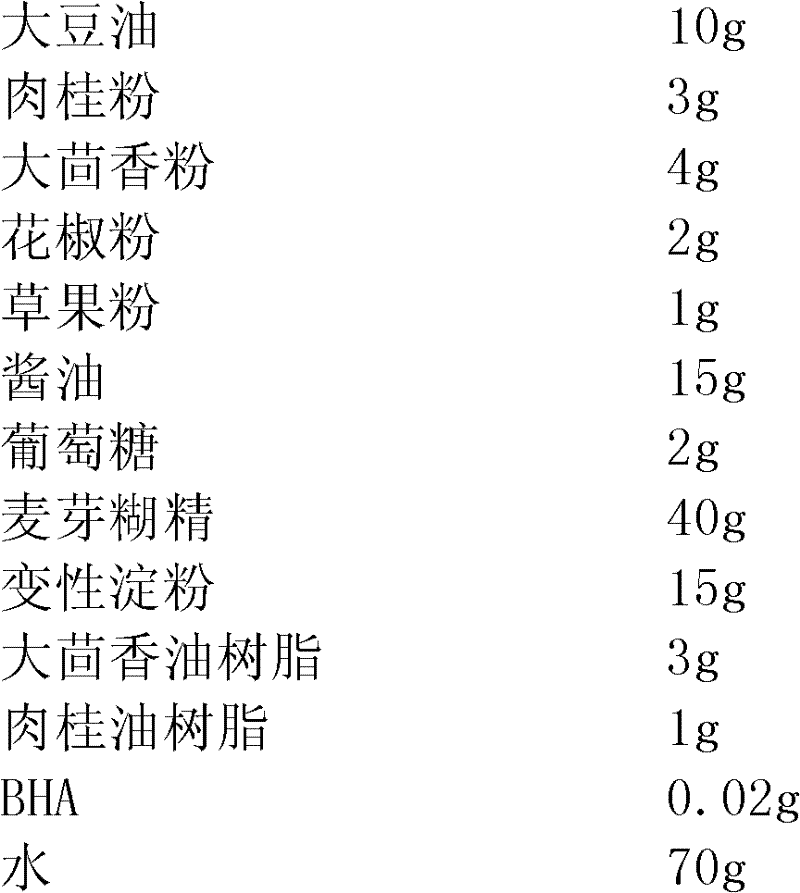

[0025] The raw materials and addition amount of braised beef seasoning paste are as follows:

[0026]

[0027]

[0028] Prepare the above-mentioned braised beef seasoning paste through the following steps:

[0029] Ground the fresh beef, added papain whose weight is 0.8% of the weight of the fresh beef, and hydrolyzed it at 65° C. for 0.5 hour to obtain a beef hydrolyzate.

[0030] Take scallions, garlic, and ginger, remove the dried leaves, wash, chop, grind them through a colloid mill, put them in a reaction kettle, add water, butter, salad oil, beef hydrolyzate, cinnamon powder, anise powder, and peppercorns after stirring Flour, grass fruit powder, soy sauce, glucose, anise oleoresin, cinnamon oleoresin, seal the reaction kettle, stir and heat to 120°C, and keep it warm for 80 minutes; then stop heating, cool to 60°C, add BHA, modified starch, malt Dextrin, stirred for 15 minutes, passed through a colloid mill, and then passed through a 40-mesh sieve to obtain brais...

Embodiment 3

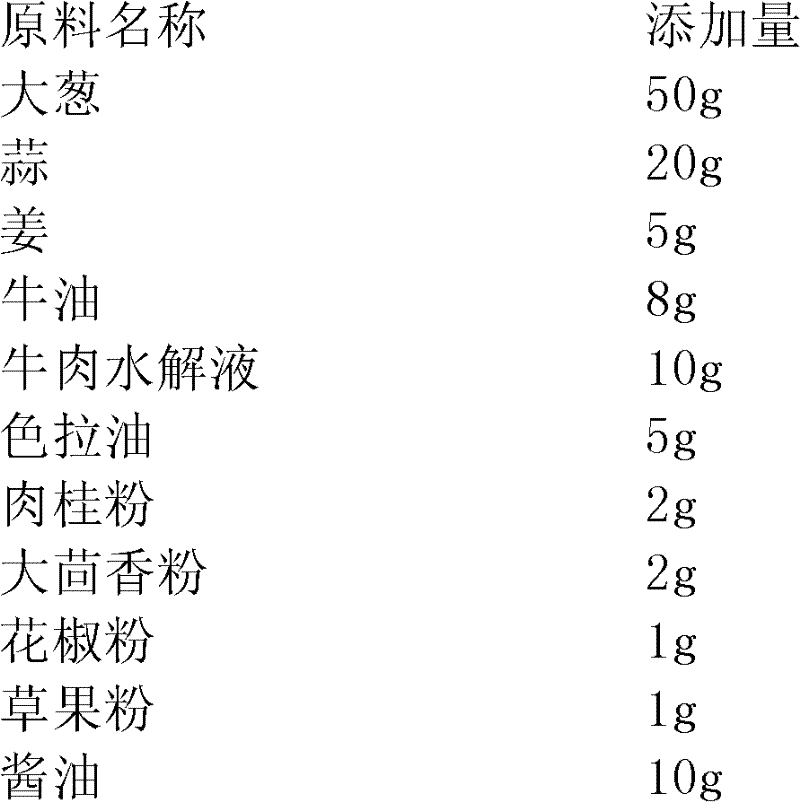

[0032] The raw materials and addition amount of braised beef seasoning paste are as follows:

[0033]

[0034]

[0035] Prepare the above-mentioned braised beef seasoning paste through the following steps:

[0036] Ground the fresh beef, added papain whose weight is 1.2% of the weight of the fresh beef, and hydrolyzed at 65° C. for 1 hour to obtain the beef hydrolyzate.

[0037] Take scallions, garlic, and ginger, remove the dried leaves, wash, chop, grind them through a colloid mill, put them in a reaction kettle, add water, butter, salad oil, beef hydrolyzate, cinnamon powder, anise powder, and peppercorns after stirring Flour, grass fruit powder, soy sauce, glucose, anise oleoresin, cinnamon oleoresin, seal the reaction kettle, stir and heat to 130°C, and keep it warm for 160 minutes; then stop heating, cool to 70°C, add BHA, modified starch, malt Dextrin, stirred for 30 minutes, passed through a colloid mill, and then passed through a 40-mesh sieve to obtain braised...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com