Waterproof, anti-corrosion and breathable expanded polytetrafluoroethylene material modified film for packaging bottle cap and preparation method thereof

A technology of polytetrafluoroethylene and packaging bottle caps, applied in chemical instruments and methods, packaging, transportation and packaging, etc., can solve the problems of acid and alkali solution corrosion, bottle caps cannot be opened, and affect economic benefits, and achieve welding Good compactness and the effect of preventing pressure balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

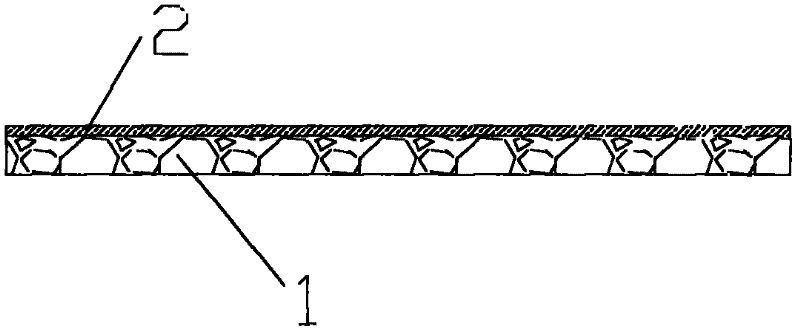

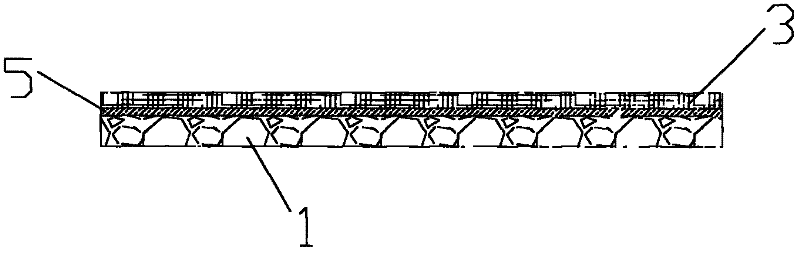

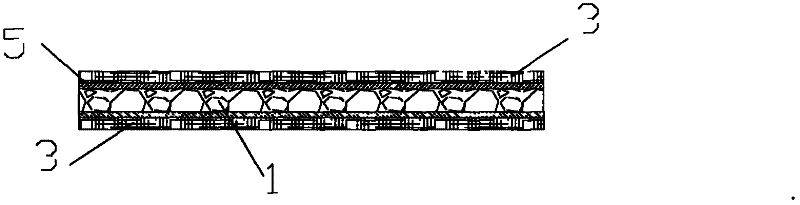

[0043] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0044] Such as Figure 1-4 Shown, a kind of expanded polytetrafluoroethylene material modified film of packaging bottle cap waterproof, anti-corrosion and breathable, comprises the expanded polytetrafluoroethylene microporous film layer 1 of enhancing oleophobic ability and with described enhanced oleophobic The ability of the expanded polytetrafluoroethylene microporous film layer 1 to connect the modified treatment layer.

[0045]The invention realizes the pressure balance and prevents the container from bursting, collapsing or leaking, realizes the requirements of waterproof, dustproof, oilproof, breathable, antioxidatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com