Method and device for preparing micro-nano composite periodic structure with femtosecond laser beam

A micro-nano composite, periodic structure technology, applied in the fields of laser nano-processing and holographic lithography, can solve the problems of lack of flexibility, monotonous periodic structure patterns, etc., and achieve the effect of improving diversity and enriching patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

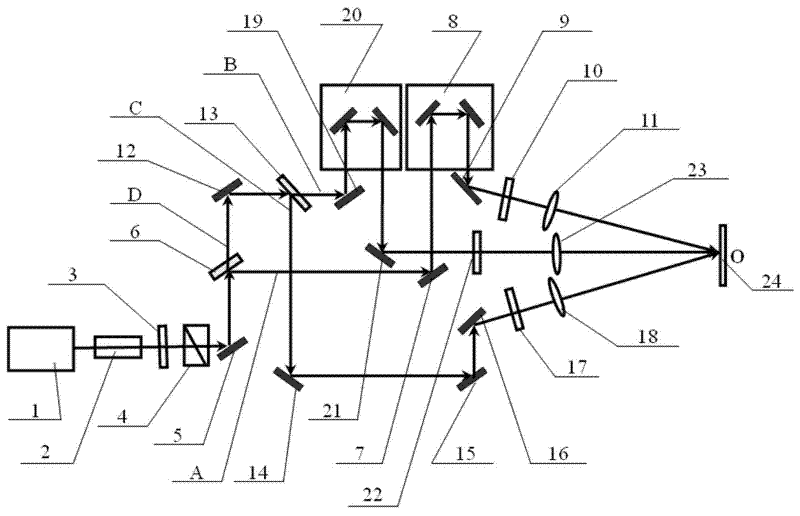

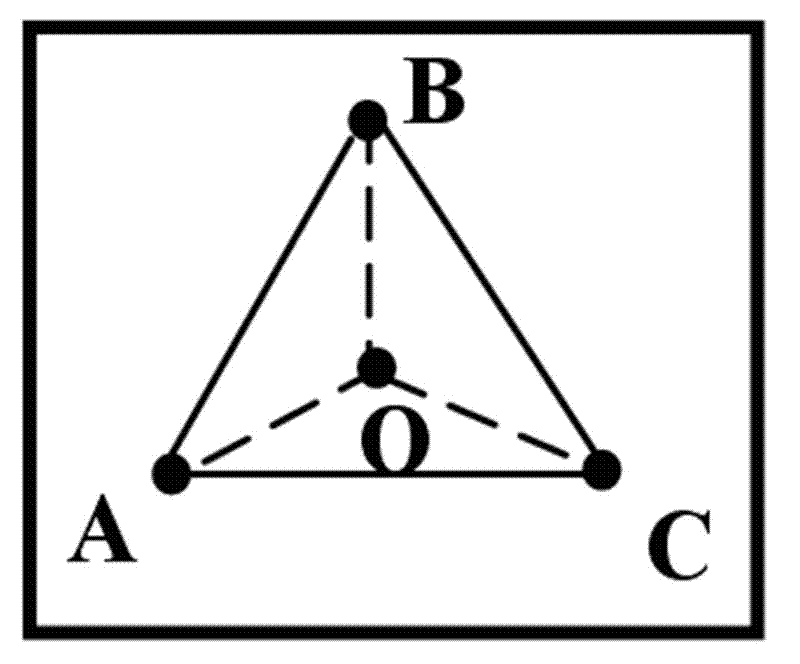

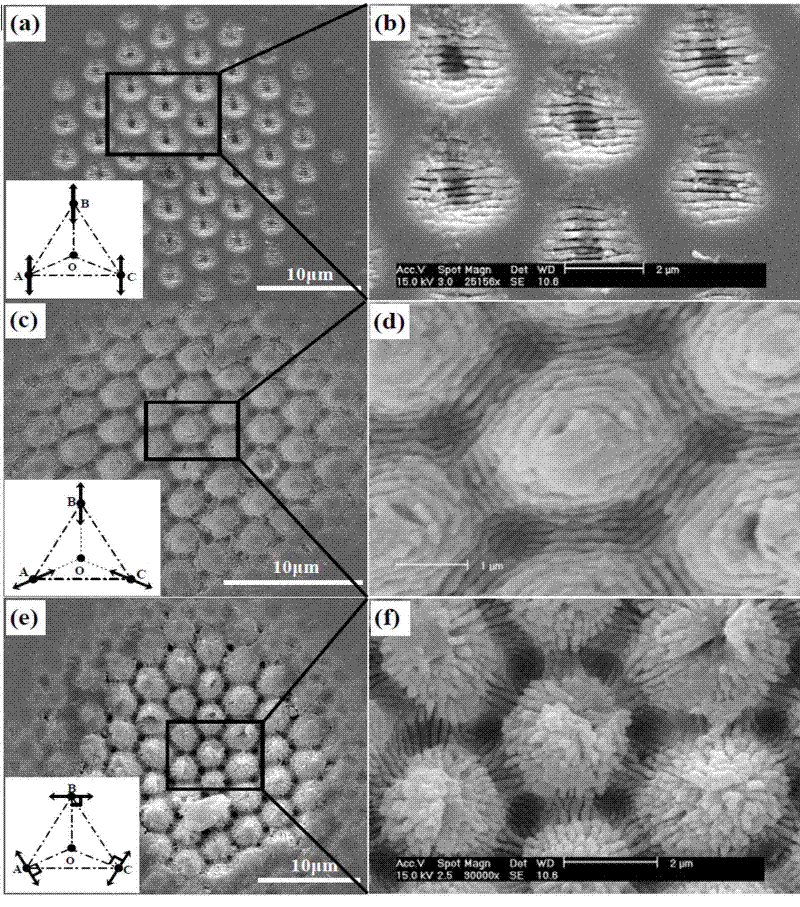

[0042] The specific implementations of the method and device for preparing a micro-nano composite periodic structure by a femtosecond laser beam of the present invention will be described in detail below with reference to the accompanying drawings.

[0043] See attached figure 1 , The femtosecond laser beam is generated by the femtosecond laser light source 1, through the electronic shutter 2 through the first half-wave plate 3 and the first Glan prism 4 to adjust the energy and polarization direction, and then through the first total mirror 5 reflected to the first After the beam splitter 6 is divided into two beams A and D, the energy ratio of the two beams is 1:2. The reflected light beam A is reflected by the second total mirror 7 to the first time delay optical path system 8, and the emitted light is reflected by the third total mirror 9 and irradiated on the sample 24 through the second half-wave plate 10 and the first converging lens 11 . The transmitted light beam D is r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com