Decolorizing method of (meth)acrylic acid

A technology of methacrylic acid mother and acrylic acid is applied in the field of decolorizing chemical raw materials in the process of refining and purification, which can solve the problem of high operating costs and achieve the effects of low energy consumption and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

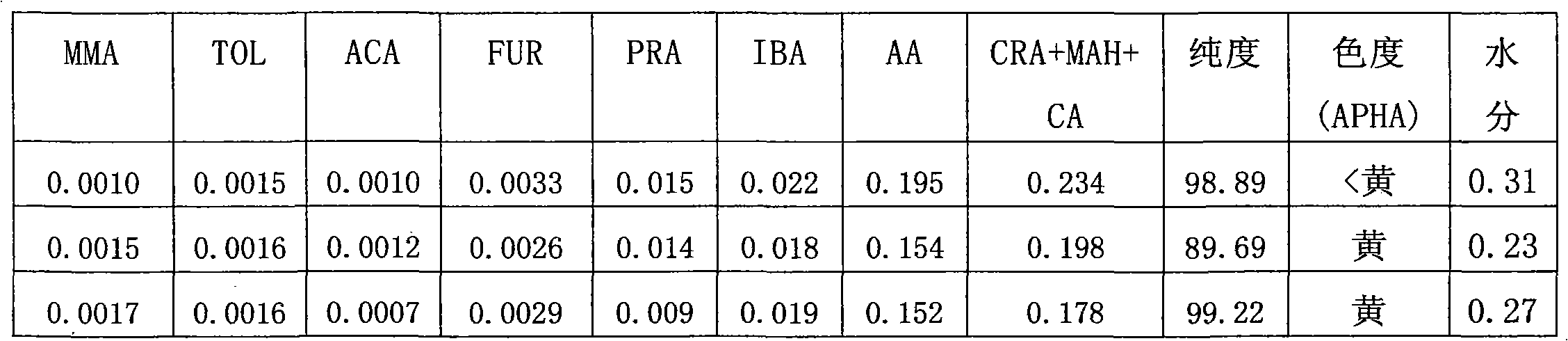

Examples

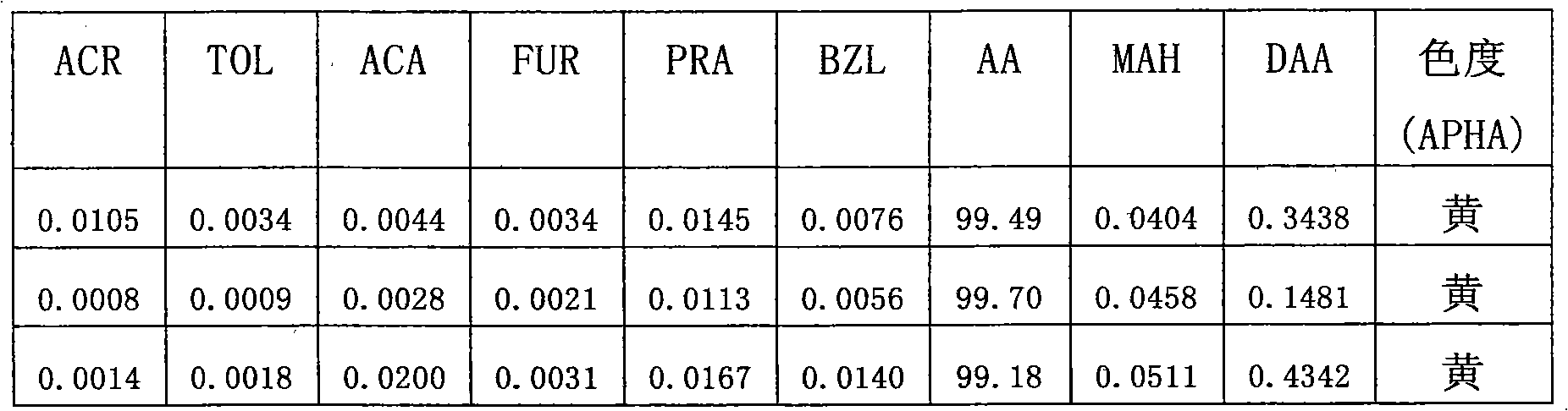

Embodiment 1

[0036] (1) Get the acrylic acid mother liquor and carry out crystallization

[0037] Get a certain amount of rough rectification, acrylic acid mother liquor (1 ton-100 tons, can be adjusted according to the needs of production capacity) that purity is 90-95% by weight, pump it to crystallizer with certain rate (crystallizer size is 1m 3 -100m 3 , can be adjusted according to production capacity requirements), and at the same time, the refrigerator is turned on for refrigeration. Methanol or ethanol as the heat exchange medium enters from the shell of the crystallizer, and the temperature of the crystallization tube is slowly cooled from normal temperature to -17°C. The cooling rate is 1°C / min. The crystallization time is controlled to be 30-40 minutes, the crystallization pressure is controlled to be 40-60 kPaG, and the temperature of the acrylic acid is lowered from normal temperature to -15--20° C., so that all acrylic acid crystals are attached to the wall of the crystall...

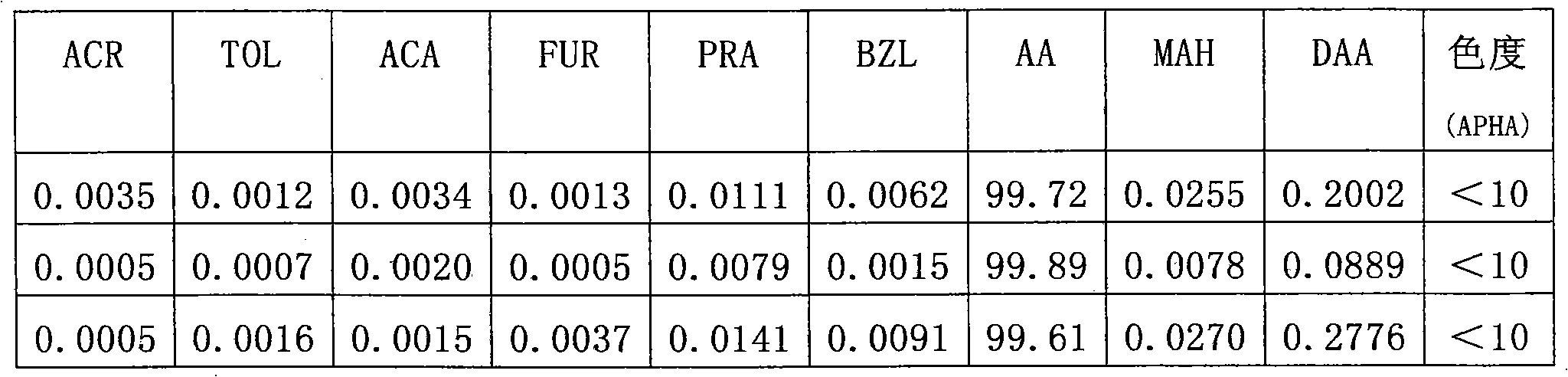

Embodiment 2

[0050] (1) Get methacrylic acid mother liquor and carry out crystallization

[0051] Same as Example 1, get a certain amount of crude distillation, methacrylic acid mother liquor (1 ton-100 tons, can be adjusted according to production capacity needs) with a purity of 90-95% by weight, and pump it to Crystallizer (the crystallizer size is 1m 3 -100m 3 , can be adjusted according to production capacity requirements), and at the same time, the refrigerator is turned on for refrigeration. Methanol or ethanol as the heat exchange medium enters from the shell of the crystallizer, and the temperature of the crystallization tube is slowly cooled from normal temperature to -18°C. The cooling rate is 1.5°C / min. The crystallization time is controlled to be 30-40 minutes, the crystallization pressure is controlled to be 20-50 kpaG, the temperature of the methacrylic acid is lowered from normal temperature to -15--20° C., so that all methacrylic acid crystals are attached to the crystal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com