A method for separating and purifying crude product l-alpha-glycerophosphocholine

A technology for separation and purification of glycerophosphocholine, applied in the direction of phosphorus organic compounds, etc., can solve the problems of complicated separation and purification, high cost, and achieve the effects of low energy consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

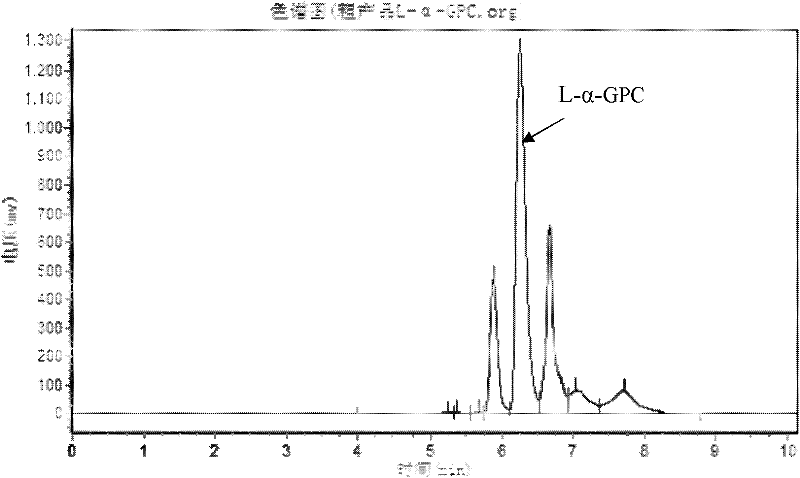

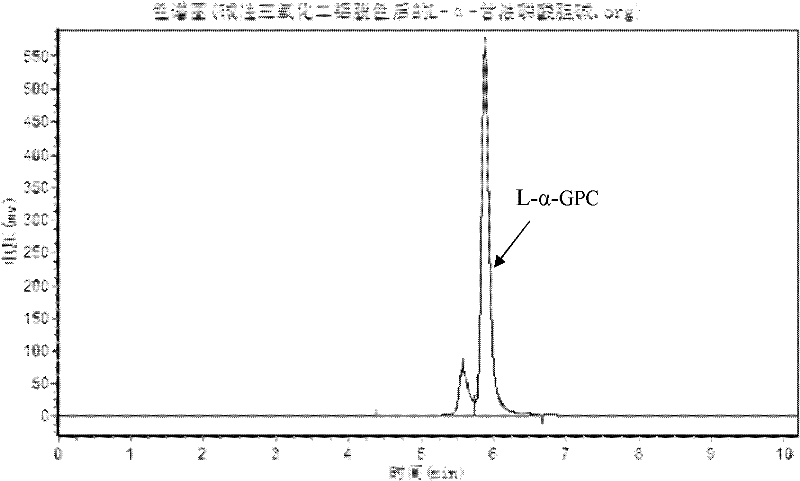

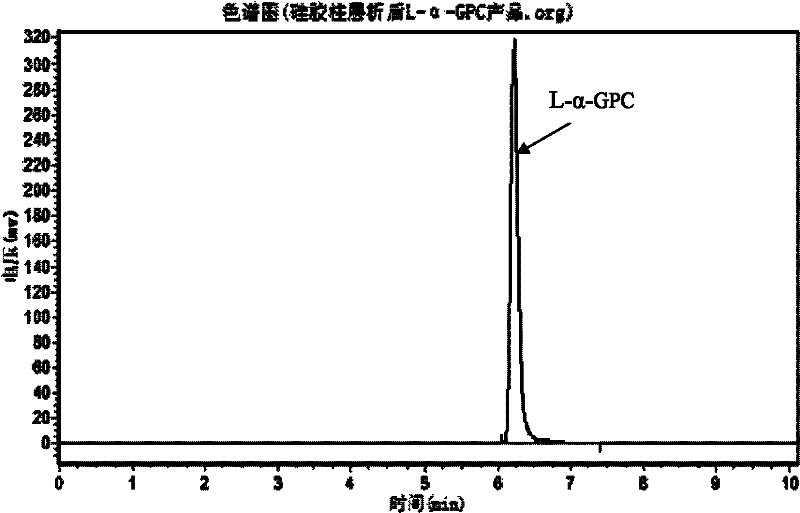

Image

Examples

Embodiment Construction

[0026] The crude product L-alpha-glycerophosphorylcholine used in the present invention is prepared by conventional methods or purchased from the market. The commercial manufacturers are Changshu Fujilai Pharmaceutical Chemical Co., Ltd., Qidong Yamei Chemical Co., Ltd. and Suzhou Industrial Park Yake Chemical Reagent Co., Ltd. company.

[0027] Non-limiting examples of the invention are as follows.

[0028] 1. Pretreatment of basic aluminum oxide and silica gel powder:

[0029] Spread basic aluminum oxide (100-200 mesh) in a container and bake in an oven at 250°C for 4 hours to obtain activated basic aluminum oxide; spread silica gel powder (100-200 mesh) In a container, bake in an oven at 105° C. for 30 minutes to obtain activated silica gel powder.

[0030] 2. Decolorization of crude product L-α-glycerophosphocholine by basic aluminum oxide:

[0031] Weigh the crude product L-α-glycerophosphocholine (dark brown), add absolute ethanol, stir and dissolve at 50°C, add 5-10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com