Solvent-free epoxy glass flake paint and manufacturing method

A technology of epoxy glass and manufacturing method, applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of decreased adhesion, penetration resistance and impact resistance, increased coating porosity and shrinkage, Solvent is easy to stay inside the coating and other problems, to achieve the effect of enhancing stability and anti-settling, small coating shrinkage, compact structure and good penetration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

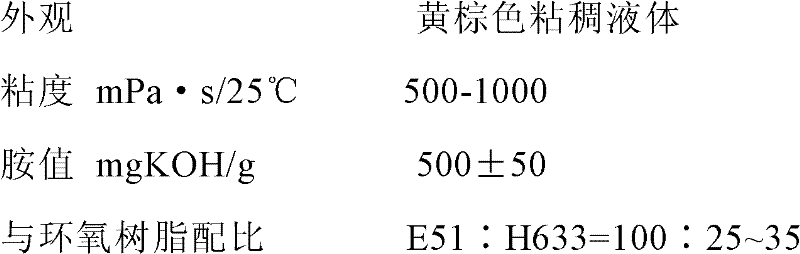

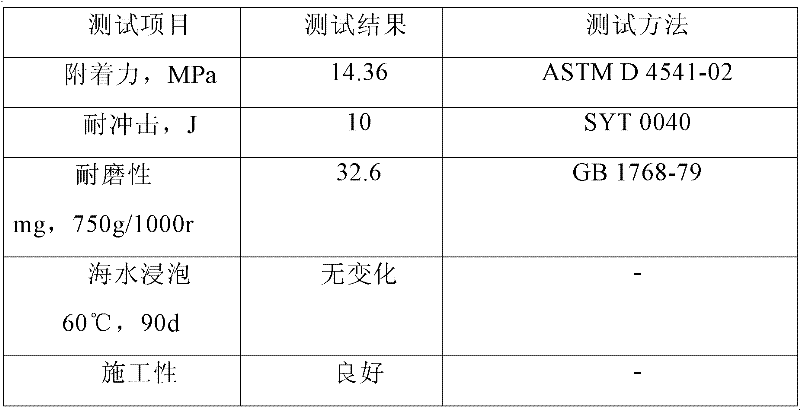

[0026] Embodiment 1: the manufacture method of solvent-free epoxy glass flake paint, in the feed tank of stainless steel, add 1 weight part bisphenol A type epoxy resin E51, add 0.13 weight part active diluent 660A to disperse and dissolve again, add 0.0008 parts by weight of silicone oil, 0.002 parts by weight of EP 2440 adhesion promoting resin, high-speed stirring, adding 0.002 parts by weight of carbon black, 0.09 parts by weight of titanium dioxide, 0.15 parts by weight of aluminum tripolyphosphate, 0.05 parts by weight of organic bentonite flow Change additive 881-B, and then use a sand mill to grind for 0.5~1h, then add 0.4 parts by weight of 80-mesh glass flakes, mix well, and make A liquid; B liquid is composed of epoxy curing agent H633, and it is used by 1 weight Part A liquid is mixed evenly with 0.2 weight part B liquid. All raw materials used are commercially available.

[0027] The workability and coating performance test results of solvent-free epoxy glass fla...

Embodiment 2

[0030] Embodiment 2: the manufacture method of solvent-free epoxy glass flake coating, in the feed bucket of stainless steel, add 1 weight part bisphenol A type epoxy resin E51, add 0.1 weight part reactive diluent 660A to disperse and dissolve again, add 0.0005 parts by weight of silicone oil, 0.001 parts by weight of EP 2440 adhesion promoting resin, high-speed stirring, adding 0.001 parts by weight of carbon black, 0.05 parts by weight of titanium dioxide, 0.1 parts by weight of aluminum tripolyphosphate, 0.01 parts by weight of organic bentonite flow Change additive 881-B, then grind it with a sand mill for 0.5~1h, then add 0.1 parts by weight of 80-mesh glass flakes, mix evenly, and make A liquid; B liquid is composed of epoxy curing agent H633, and it is used by 1 weight Part A liquid is mixed with 0.2 weight part B liquid. All raw materials used are commercially available.

Embodiment 3

[0031] Embodiment 3: the manufacture method of solvent-free epoxy glass flake paint, in the feed tank of stainless steel, add 1 weight part bisphenol A type epoxy resin E51, add 0.15 weight part reactive diluent 660A to disperse and dissolve again, add 0.001 parts by weight of silicone oil, 0.005 parts by weight of EP 2440 adhesion promoting resin, high-speed stirring, adding 0.005 parts by weight of carbon black, 0.1 parts by weight of titanium dioxide, 0.2 parts by weight of aluminum tripolyphosphate, 0.05 parts by weight of organic bentonite flow Change additive 881-B, and then use a sand mill to grind for 0.5~1h, then add 0.5 parts by weight of 80-mesh glass flakes, mix well, and make A liquid; B liquid is composed of epoxy curing agent H633, and it is used by 1 weight Part A liquid is mixed with 0.25 weight part B liquid. All raw materials used are commercially available.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com