Antibacterial stainless steel composite steel plate and its manufacturing method

An antibacterial stainless steel and composite steel plate technology, applied in the field of metallurgy, can solve the problems of increased manufacturing cost, limitation of element types, and difficulty of preparation process control, and achieves the effect of taking into account corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

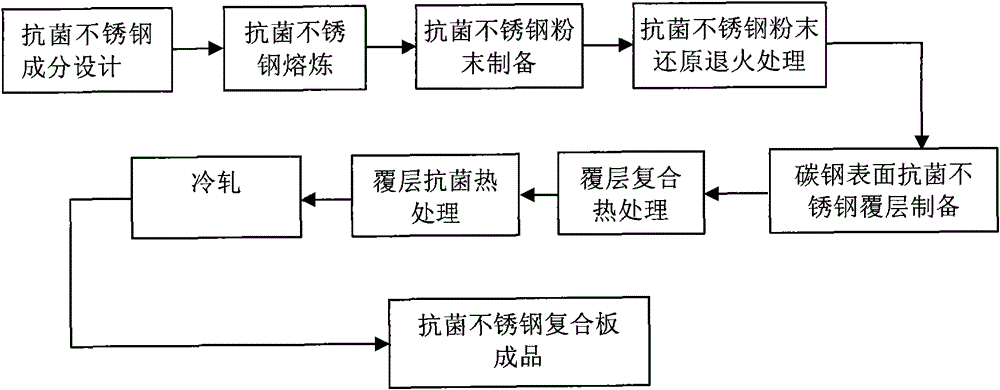

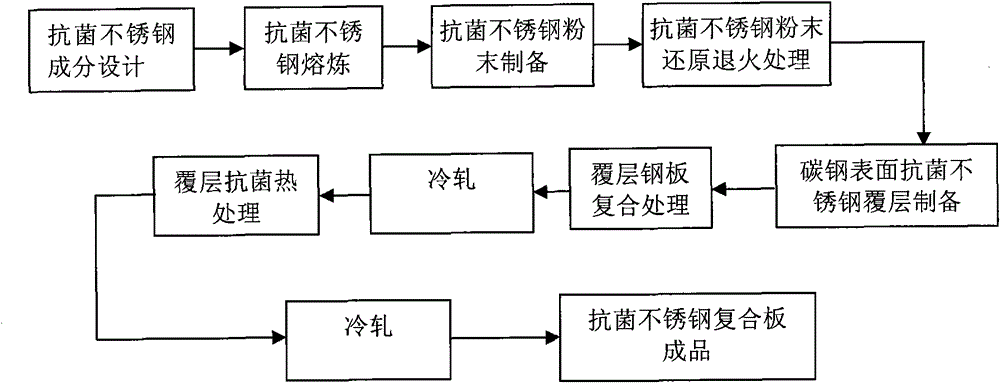

[0062] The preparation process of embodiment 5 and embodiment 7 is as follows figure 2 As shown, its specific process parameters are shown in Table 3-Table 6.

[0063] Table 3 Preparation process of antibacterial stainless steel powder

[0064]

[0065] Example 4

3mm

1500℃

1.8MPa

5-38μm

450℃

Ammonia solution gas

0.25%

Example 5

3mm

1500℃

1.8MPa

5-38μm

450℃

Ammonia solution gas

0.18%

Example 6

3mm

1500℃

1.8MPa

5-40μm

450℃

Ammonia solution gas

0.18%

Example 7

3mm

1500℃

1.8MPa

5-40μm

450℃

Ammonia solution gas

0.20%

Example 8

4mm

1480℃

1.8MPa

5-58μm

400℃

Ammonia solution gas

0.10%

Example 9

4mm

1480℃

1.7MPa

5-58μm

300℃

Ammonia solution gas

0.15%

Example

10

4mm

1480℃

1.7MPa

5-58μm

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com