Surfacing repair material for mold

A technology for repairing materials and molds, which is applied in the field of surfacing repairing materials and surfacing materials for mold repairing. It can solve the problems of high surface quality, high wear resistance, and high hardness, and achieve high-temperature softening resistance and strong corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

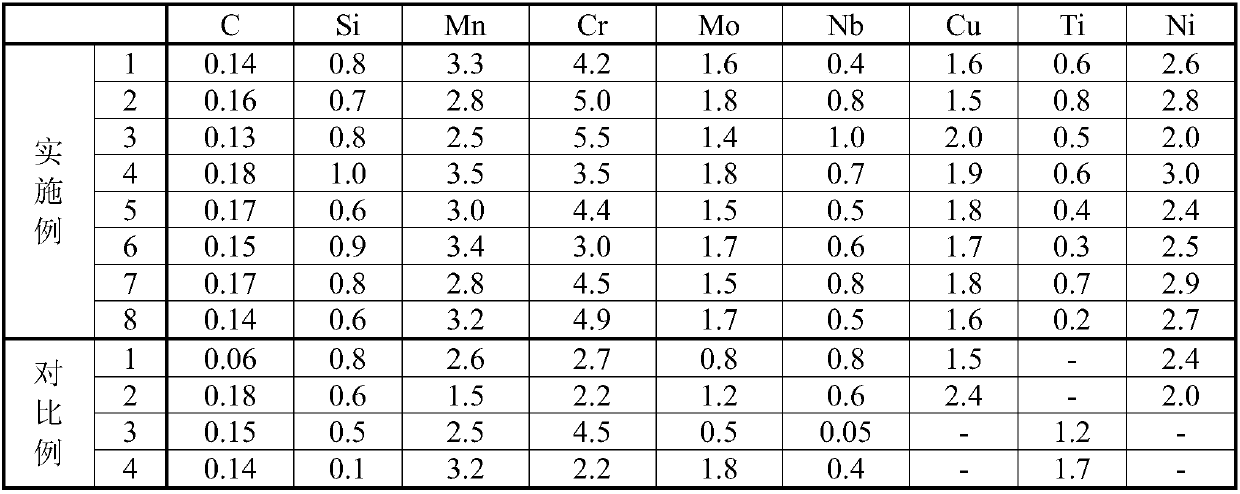

[0043] Make a welding wire with a diameter of 2.0mm, and the composition is shown in Table 1.

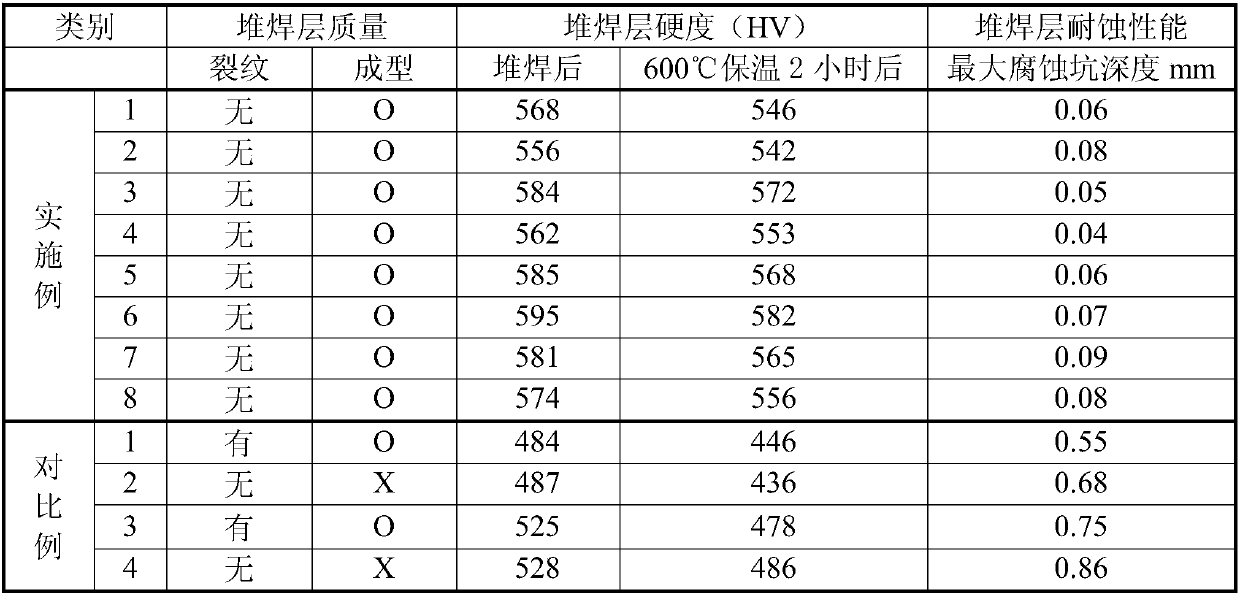

[0044] The welding test is TIG welding, the shielding gas is pure argon, the flow is 8L / min, the current is 120A, and the voltage is 13V. The quality and performance of the surfacing layer are shown in Table 2.

Embodiment 3-4

[0046] Make welding wire with a diameter of 2.4mm, and the composition is shown in Table 1.

[0047] The welding test is TIG welding, the shielding gas is pure argon, the flow is 10L / min, the current is 140A, and the voltage is 14V. The quality and performance of the surfacing layer are shown in Table 2.

Embodiment 5-6

[0049] Make welding wire with a diameter of 1.6mm, and the composition is shown in Table 1.

[0050] The welding test is gas shielded welding, and the shielding gas is 98%Ar+2%CO 2 , The flow rate is 12L / min, the current is 240A, and the voltage is 25V. The quality and performance of the surfacing layer are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com