Servo-controlled hydraulic vibration excitation system for high-speed rail track subgrade testing

A servo control and track technology, applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc., can solve the problem that the excitation system is difficult to meet the requirements of high-speed rail track roadbed testing, and it is difficult to meet the high vibration frequency at the same time. and high excitation force, large hydraulic system flow, etc., to achieve the effect of good system dynamic response, small dynamic load, and small hydraulic system flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, which are not intended to limit the protection scope thereof.

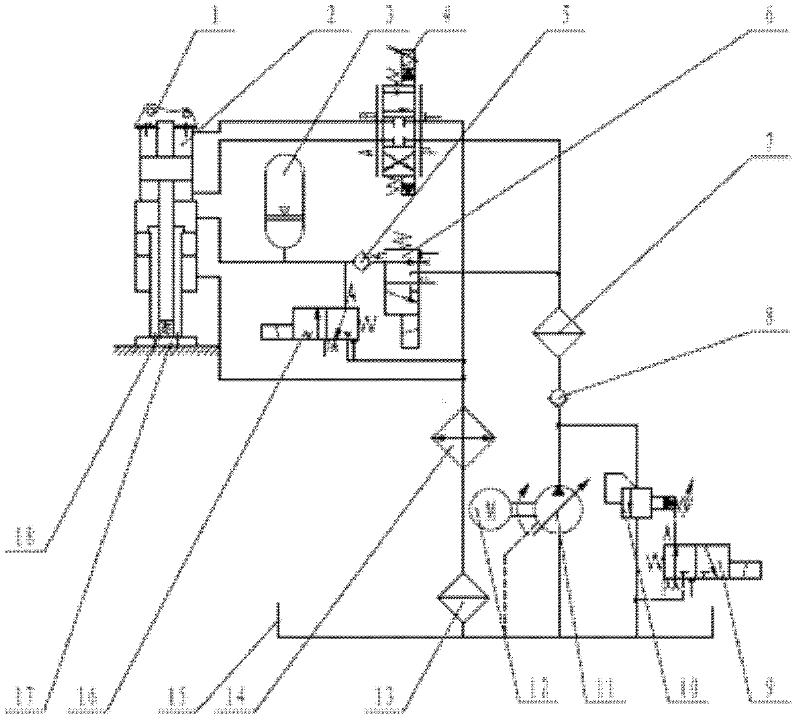

[0030] A servo-controlled hydraulic vibration excitation system for high-speed rail track subgrade testing. The system as figure 1 As shown: the oil pump 11 is coaxially connected with the motor 12, the oil suction port of the oil pump 11 communicates with the oil tank 15 through the oil pipe, and the oil pressure port of the oil pump 11 is connected to the oil inlet of the relief valve 10 and the inlet of the first check valve 8 through the oil pipe. The oil ports communicate with each other, the oil outlet of the overflow valve 10 communicates with the oil tank 15 through the oil pipe, the control port of the overflow valve 10 communicates with the A port of the second electromagnetic reversing valve 9, and the T port of the second electromagnetic reversing valve 9 It communicates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com