Semiconductor laser and light field splicing method for realizing large-angle uniform irradiation

A uniform irradiation and laser technology, applied in the field of lasers, to achieve the effects of narrow spectral width, uniform radiation, and high radiation power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

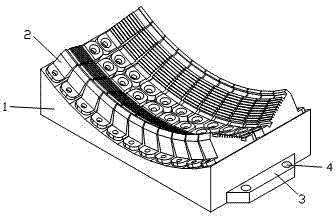

[0033] Embodiment 1 (the embodiment of semiconductor laser described in the present invention, see Figure 1-Figure 3 ):

[0034] A semiconductor laser that realizes large-angle uniform irradiation is characterized in that it includes a base 1 whose upper surface is an arc surface and at least one set of laser array unit groups arranged in the direction of the fast axis; the laser array unit group consists of at least one in the slow The laser array unit 2 arranged in the axial direction is composed of; the number of the laser array unit group is the required angle of irradiation of the laser in the fast axis direction / the full width at half maximum angle of the slow axis of the bar 21; the number of laser array units 2 in the laser array unit group : The laser irradiates the required angle in the direction of the slow axis / the angle at half maximum of the slow axis of the bar 21;

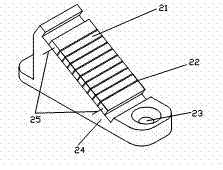

[0035] The laser array unit includes a triangular wedge-shaped tube base 24, a semiconductor l...

Embodiment 2

[0043] Embodiment 2 (the embodiment of the element splicing method of the semiconductor laser described in the present invention, see figure 1 —3):

[0044]Realize the method for splicing the light field of the semiconductor laser of large-angle uniform irradiation, it is characterized in that carrying out according to the following steps:

[0045] 1) Calculate the number of laser array unit groups: the required angle of irradiation of the laser in the direction of the fast axis / the angle of the full width at half maximum of the slow axis of the laser;

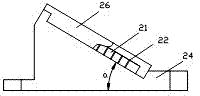

[0046] 2) Determine the angle α of the triangular wedge-shaped tube seat: it is the complementary angle of the fast axis full width at half maximum angle of the laser;

[0047] 3) Calculate the number of bars 21 included in the semiconductor laser core group: total output power required by the laser / output power of each bar;

[0048] 4) Calculate the number of laser array units 2 in the laser array unit group: the required a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Luminous power | aaaaa | aaaaa |

| Luminous power | aaaaa | aaaaa |

| Luminous power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com