Straw recycling granulation locomotive

A granulator and locomotive technology, applied in the field of agricultural machinery, can solve the problems of safety and fire hazards, time-consuming and labor-intensive, and large space occupation, and achieve the effects of improving work efficiency, convenient and quick operation, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

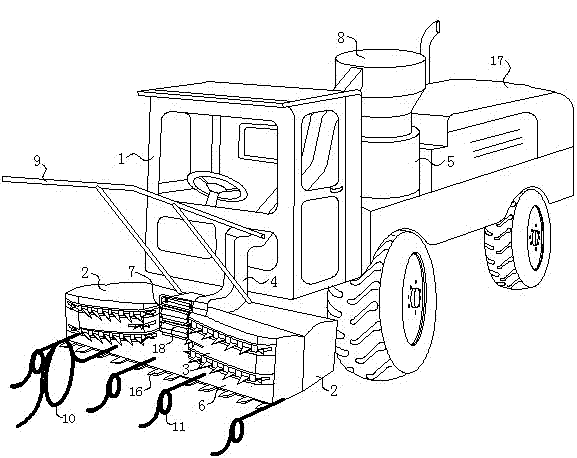

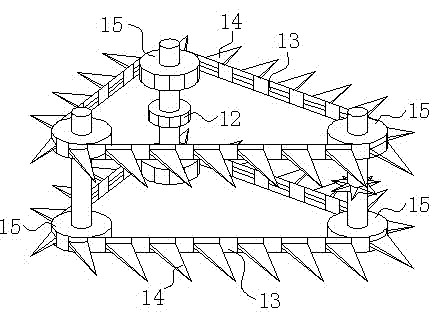

[0014] The straw recovery and granulation operation locomotive of the present invention is composed of a locomotive 1, a harvester 2, a gathering feeder 3, a material lifting cylinder 4 and a rolling granulator 5. The harvester 2 is connected to the bottom of the front end of the cab of the locomotive 1, and an inwardly inclined retracting feeder 3 is respectively provided on both sides of the cutting tooth plate 6, and a camera is arranged between the two retracting feeders 3. Feed port 7, feed port 7 is to be provided with inwardly to roll the feed roller 18 in front of the door, and interlockingly forms with the guillotine cutter and the kneading roller of setting inside. The intake port 7 sends the material to the hopper 8 of the rolling granulator 5 through the conveyor belt in the material lifting cylinder 4, and the front-stretched centralizer 9 is fixed on the chassis of the harvester 2, and the rolling granulator 5 fixed seats are on the chassis of locomotive 1. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com