High vacuum distillation purification device

A high-vacuum, falling-film evaporator technology, used in vacuum distillation, evaporation, evaporator accessories, etc., can solve the problems of low yield and content of carbonized or cracked products, easy oxidation of materials, small processing capacity, etc. The effect of short time, reduction of thermal polymerization or thermal decomposition, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

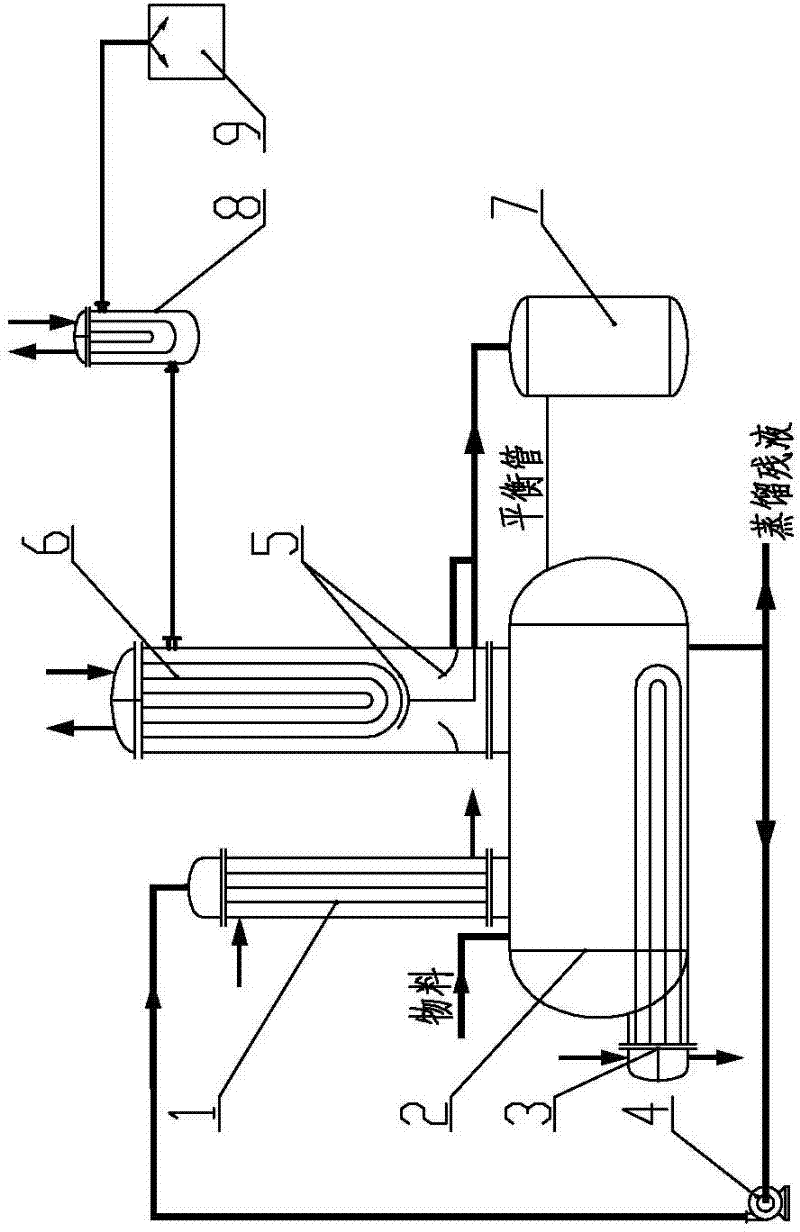

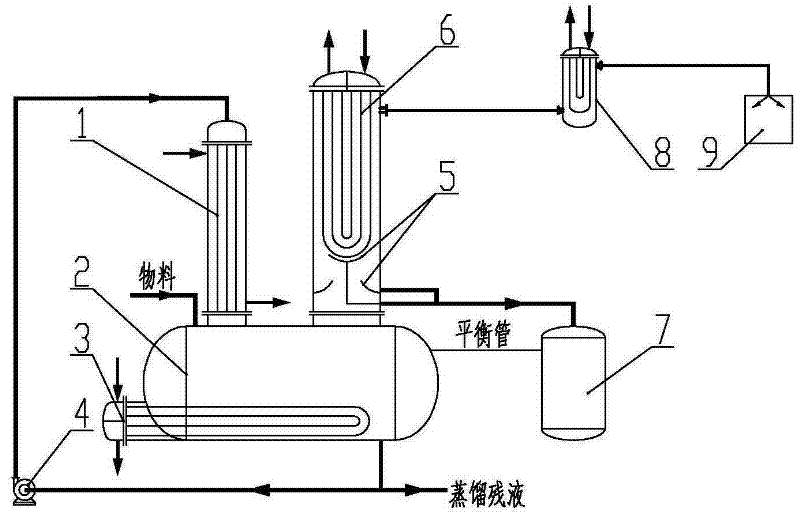

[0024] As can be seen from the figure below, the device of the present invention at least includes a falling film evaporator 1, a gas-liquid separator 2, a U-shaped tube heater 3, a material circulation pump 4, a liquid receiving pan 5, a U-shaped tube condenser 6, and a liquid receiving tank 7, cold trap 8, vacuum pump unit 9 and connecting pipeline,

[0025] The feed port at the top of the falling film evaporator 1 is connected with the discharge port of the material circulation pump 4, the suction port of the material circulation pump 4 is connected with the discharge port at the bottom of the gas-liquid separator 2, and the liquid receiving tank 7 The feed port is connected to the discharge port of the U-shaped tube condenser 6, the gas-liquid separator 2 is connected to the liquid receiving tank 7 through a balance pipe, and the air inlet of the cold trap 8 is connected to the exhaust of the U-shaped tube condenser 6. The air inlet of the vacuum pump unit 9 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com