A kind of regeneration method of activated clay waste residue

A technology of activated clay waste residue and sulfuric acid solution, which is applied in separation methods, filter regeneration, chemical instruments and methods, etc., and can solve the problems of land occupation, pollution of the surrounding environment, waste of material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

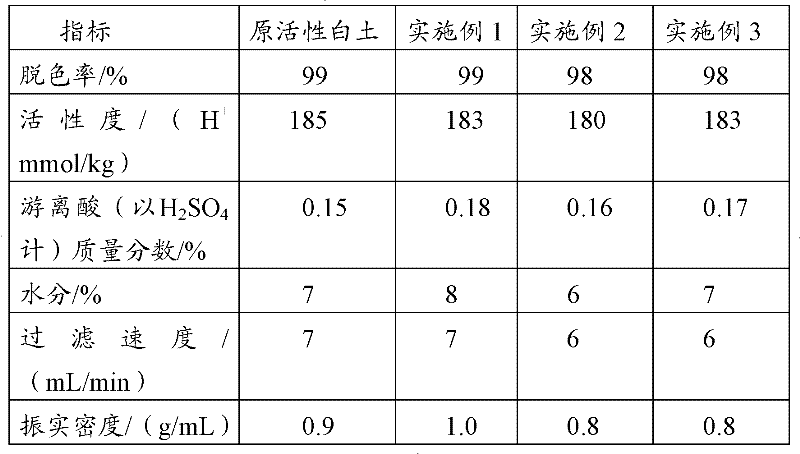

Examples

Embodiment 1

[0025] The activated clay produced by Guangzhou Qitong Chemical Co., Ltd. is used for the decolorization and filtration of oils, and the activated clay waste generated from oil treatment is clarified and dried, and then mixed with a sulfuric acid solution with a concentration of 50% by mass at a mass ratio of 1:1. The mud is made into a brick shape with a size of about 5cm×5cm×5cm.

[0026] Put the finished solid in a furnace and burn it at 650°C. After 14 minutes, the solid is smokeless and tasteless, and the whole body is red. Take it out, air it to room temperature, and then pulverize with a pulverizer.

Embodiment 2

[0028] The activated clay produced by Guangzhou Qitong Chemical Co., Ltd. is used for the decolorization and filtration of oils, and the activated clay waste generated from oil treatment is clarified and dried, and then mixed with a sulfuric acid solution with a concentration of 40% by mass at a mass ratio of 0.5:1. The mud is made into a spherical shape about 5 cm in diameter.

[0029] Put the finished solid into a furnace and burn it at 600°C. After 18 minutes, the solid is smokeless and tasteless, and the whole body is red. Take it out, air it to room temperature, and then pulverize with a pulverizer.

Embodiment 3

[0031] The activated clay produced by Guangzhou Qitong Chemical Co., Ltd. is used for the decolorization and filtration of oils. The activated clay waste generated from oil treatment is clarified and dried, and then mixed with a sulfuric acid solution with a concentration of 60% by mass at a mass ratio of 1.5:1. The mud is made into granules.

[0032] Put the finished solid in a furnace and burn it at 700°C. After 11 minutes, the solid is smokeless and tasteless, and the whole body is red. Take it out, air it to room temperature, and then pulverize with a pulverizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com