An electrodialysis concentration salt production device

An electrodialysis and electrode technology, which is applied in the field of water treatment, can solve the problems of a large amount of energy consumption and increase the cost of salt production, and achieve the effects of reducing energy consumption, prolonging service life, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

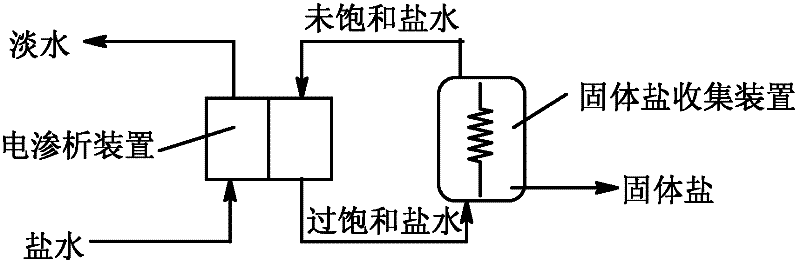

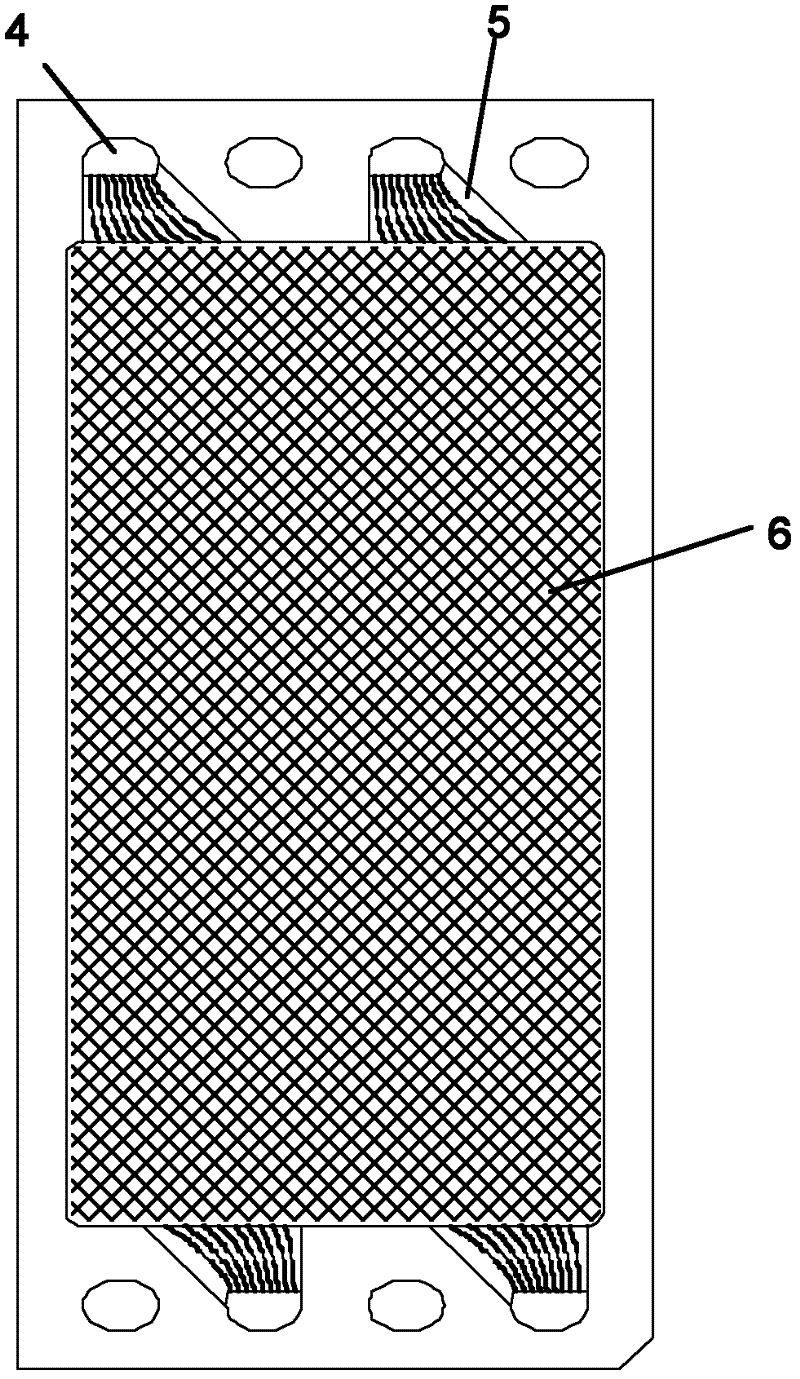

[0028] according to Figure 1-6 The principle structure shown is to install an electrodialysis concentrated salt production device, which includes an electrodialysis mechanism, a solid salt separation and collection mechanism, and a solid salt separation and collection mechanism including membrane stacks, electrodes, separators and flow channel partitions. The electrodes are platinum coatings with a thickness of 3 microns. Platinum-coated titanium electrodes, the separator is a composite elastic separator, made of PVC, the thickness of the separator is 0.8mm, each water distribution port 4 is connected with a water distribution channel plate 5, and each water distribution channel plate 5 is distributed with 12 water distribution channels, the width of the water distribution channel is 0.4mm, and the depth is 0.4mm; the solid salt separation and collection mechanism includes a supersaturated brine inlet 9, an unsaturated brine outlet 10, an inclined plate 11, and a solid salt di...

Embodiment 2

[0031] An electrodialysis concentrated salt production device, including an electrodialysis mechanism, a solid salt separation and collection mechanism, and a solid salt separation and collection mechanism including membrane stacks, electrodes, separators and flow channel partitions, wherein the electrode is a titanium-coated ruthenium electrode with a coating thickness of 5 microns, wherein The coating is made of TiO 2 , RuO 2 , IrO 2 The eutectic, wherein the mass ratio is 5:3:1. The thickness of the composite elastic partition is 0.7mm, and each channel opening is processed with 10 water distribution channels, the width of the water distribution channel is 0.5mm, and the depth is 0.5mm; the negative membrane adopts AMT homogeneous ion exchange membrane; the positive membrane adopts CMS2 1- Divalent separation homogeneous ion exchange membrane; its membrane resistance is 0.4Ω / cm 2 ;Crosslinking degree is 85%, film thickness is 0.10mm; electrodialysis current density is 70...

Embodiment 3

[0034] With the same device shown in Example 2, industrial waste water containing 3.0% sodium sulfate was used as the influent to enter the electrodialysis dilute chamber. Membrane stack electrodes are made of titanium-coated ruthenium electrodes with a coating thickness of 15 microns; the composite elastic separator is a PC board with a thickness of 0.8 mm, and each channel opening is processed with 10 water distribution channels with a width of 0.6 mm and a depth of 0.6 mm. mm; the negative membrane adopts AMV homogeneous ion exchange membrane; the positive membrane adopts CMF2 1-2 valence separation homogeneous ion exchange membrane; its membrane resistance is 0.6Ω / cm 2 ; The degree of cross-linking is 75%, the film thickness is 0.15mm; the current density of electrodialysis is 700A / m 2 , the membrane surface flow velocity is 15m / s, and the electrodialysis operating water temperature is 35°C. After concentrated operation by electrodialysis, the fresh water in the fresh wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com