Heat accumulating type external hot coal middle-low temperature pyrolysis furnace

A low-temperature pyrolysis and regenerative technology, used in coke ovens with vertical carbonization chambers, coke ovens, special forms of dry distillation, etc., can solve the problems of low gas calorific value, reduced lump coal ratio, and high operating costs. The effect of high calorific value of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Following accompanying drawing, the present invention is described further:

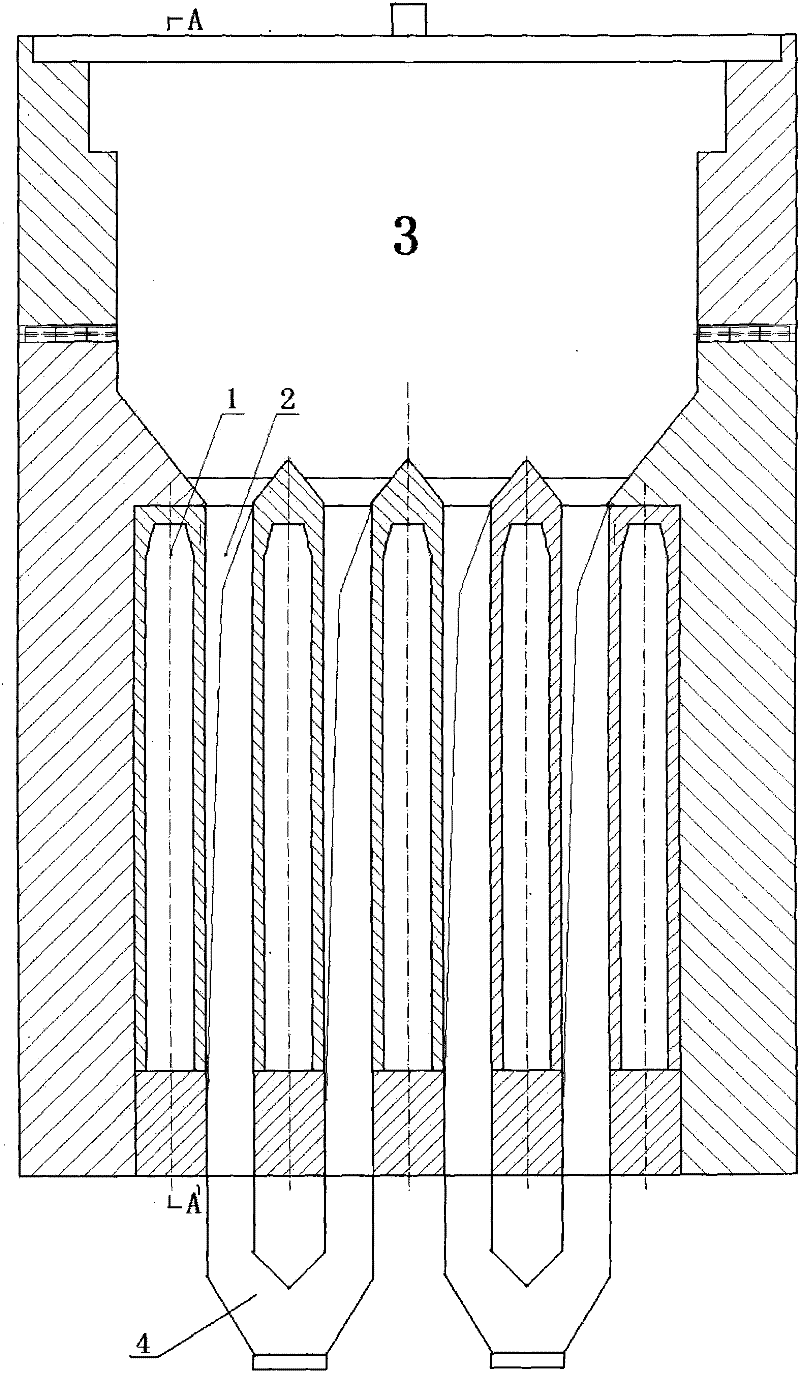

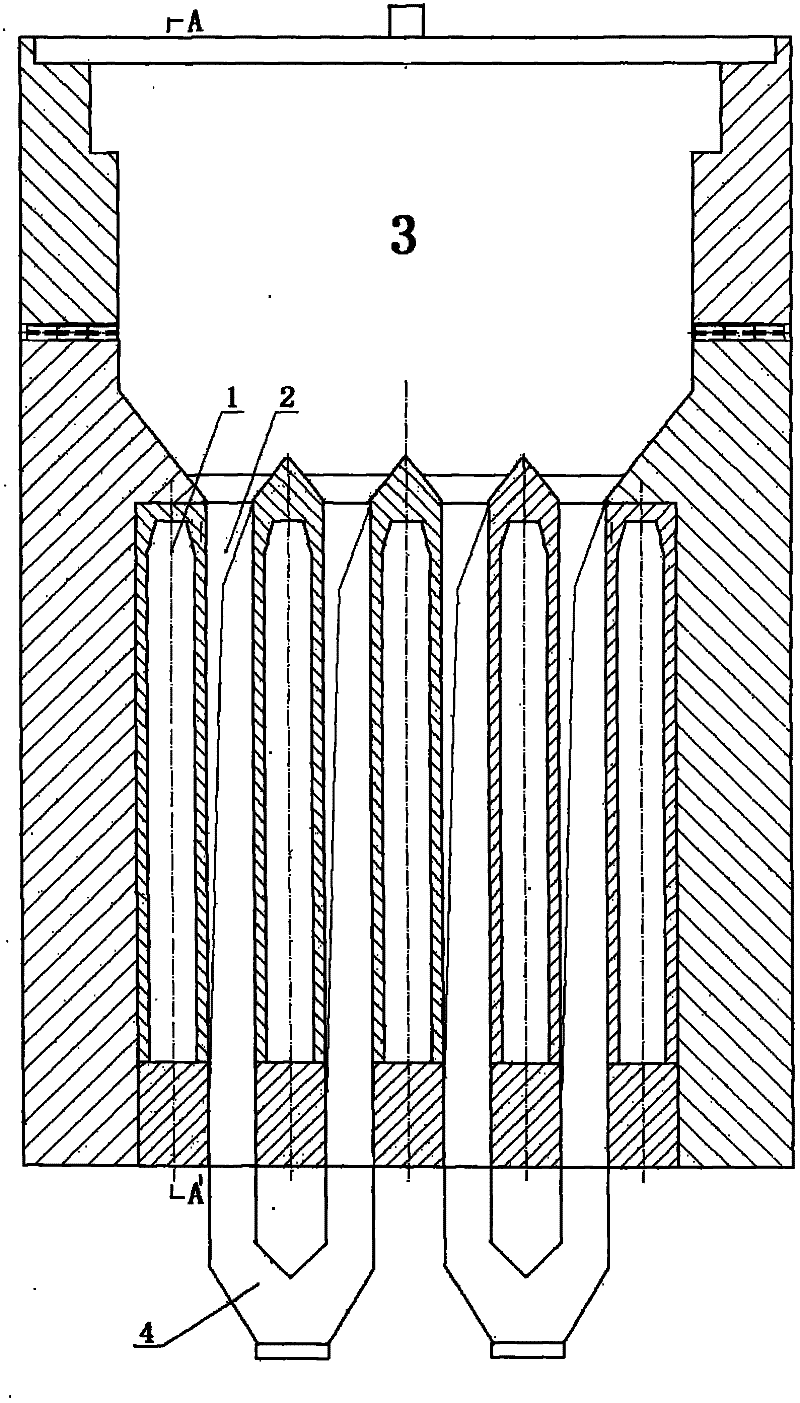

[0017] Such as figure 1 As shown, a regenerative external thermal coal medium-low temperature pyrolysis furnace is characterized in that it includes a combustion chamber 1, and a carbonization chamber 2 arranged in parallel with the combustion chamber 1, the carbonization chamber 2 and the coal preheating bin 3 on the top connect.

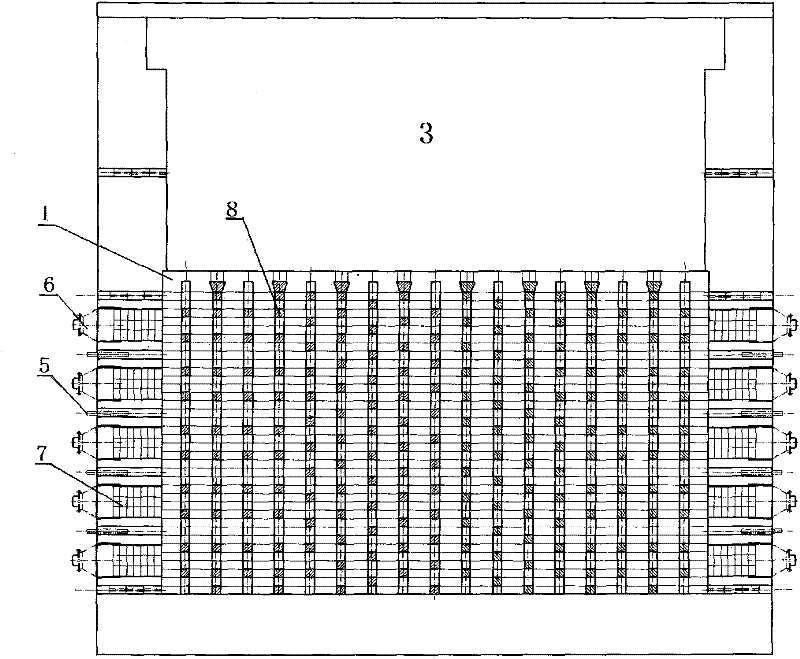

[0018] Such as figure 2 As shown, the end of the combustion chamber 1 is arranged at intervals from bottom to top with regenerators 6, and regenerators 7 are arranged in the regenerators 6; The chamber 1 is provided with a clean gas inlet 5 .

[0019] The heat storage body 7 is made of high alumina, mullite or corundum.

[0020] The combustion chamber 1 is provided with a reinforcement structure 8, the reinforcement structures 8 are arranged in a staggered manner, the reinforcement structure 8 plays a role in supporting the combustion chamber 1 in the combusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com