A kind of hydrate storage and boxing equipment

A hydrate and equipment technology, applied in mechanical equipment, gas/liquid distribution and storage, pressure vessels, etc., can solve the problems of solid-liquid separation and poultry, reduce investment and land occupation, prevent static electricity generation, and enhance sliding effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

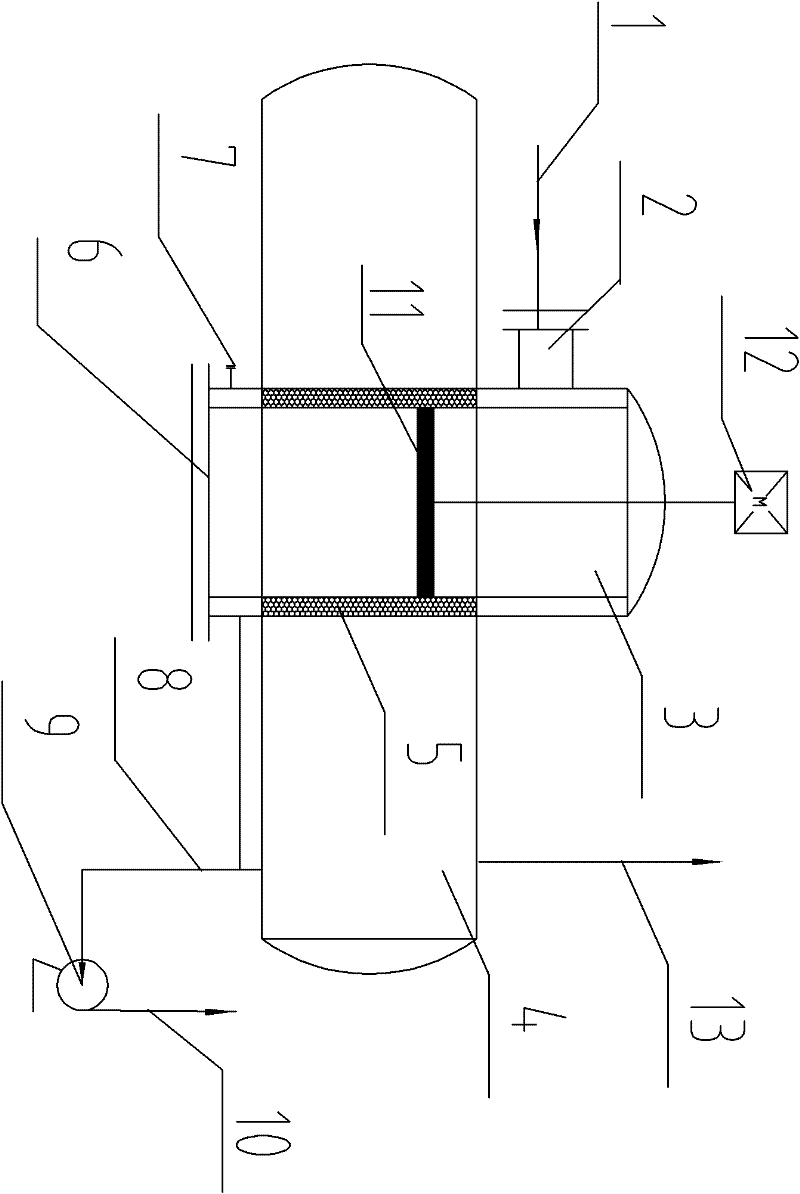

[0053] The solid hydrate storage equipment of the present invention, under the conditions of 2-10MPa pressure and temperature as the relevant operating temperature, sends the solid-liquid mixed phase material of water and hydrate into the hydrate collection tank and separates the solid hydrate by filtration. and then sent to the hydrate storage tank through the hydrate transportation facilities. It mainly includes the following equipment:

[0054] a. Hydrate collection tank 3

[0055] b. Hydrate solid-liquid separation tank 4

[0056] c. Filtration facility 5

[0057] e. Circulating water pump 9

[0058] d. Hydrate delivery piston 11

[0059] e. Hydrate transport motor 12

[0060] The above equipment is combined into one equipment, commonly known as hydrate storage and canning equipment;

[0061] Including the following steps:

[0062] ① Raw materials are transported into the storage tank

[0063] The hydrate solid-liquid mixed phase material from the hydrate reactor i...

Embodiment 2

[0071] The solid hydrate storage equipment of the present invention, under the conditions of 2-10MPa pressure and temperature as the relevant operating temperature, sends the solid-liquid mixed phase material of water and hydrate into the hydrate collection tank and separates the solid hydrate by filtration. and then sent to the hydrate storage tank through the hydrate transportation facilities. It mainly includes the following equipment:

[0072] a. Hydrate collection tank 3

[0073] b. Hydrate solid-liquid separation tank 4

[0074] c. Filtration facility 5

[0075] e. Circulating water pump 9

[0076] d. Hydrate delivery piston 11

[0077] e. Hydrate transport motor 12

[0078] Including the following steps:

[0079] ① Raw materials are transported into the storage tank

[0080] Transport the hydrate solid-liquid phase mixture material through the submarine hydrate transport equipment, and transport the solid-liquid mixed phase material to the feed nozzle 2 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com