Cooking flavor green Chinese onion powder and preparation method thereof

A technology of green onion powder and scallion powder, which is applied in the field of food processing, can solve the problems of unsatisfactory kitchen flavor development trend and thin taste, and achieve the effects of low production cost, strong taste and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

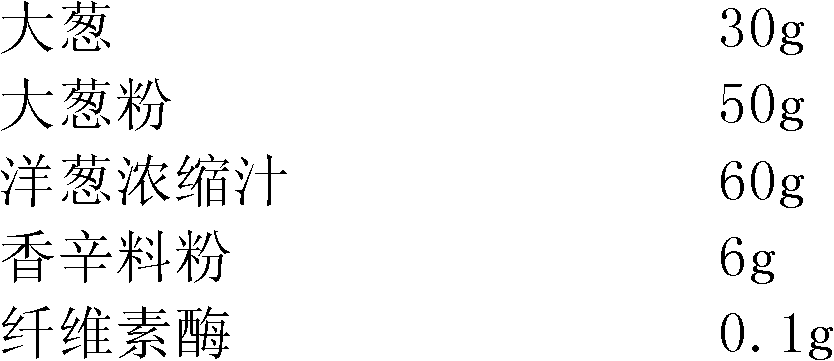

[0023] The raw materials and quality of cooking onion powder are as follows:

[0024]

[0025]

[0026] The spice powder is a mixture of anise powder, prickly ash powder and cinnamon powder in a ratio of 1:1:1 by weight.

[0027] The above-mentioned cooking seasoning powder is prepared by the following method:

[0028] (1) Take 30g green onion, remove the dry leaves, wash, chop, grind through a colloid mill, put it into a reaction kettle, add 0.1g of cellulase at the same time, stir and heat to 70°C, keep warm, and enzymatically hydrolyze for 1 hour to obtain Scallion enzymatic solution;

[0029] (2) Put 50g of scallion powder, 60g of concentrated onion juice, 6g of spice powder, 15g of edible oil, and 80g of water into the reaction kettle, mix with the scallion enzymatic solution, stir at the same time, airtight, heat to 125°C, and keep warm for 120 minutes;

[0030] (3) Stop heating, after cooling to 60°C, add 0.01g of BHA, 0.5g of xanthan gum, and 15g of maltodextri...

Embodiment 2

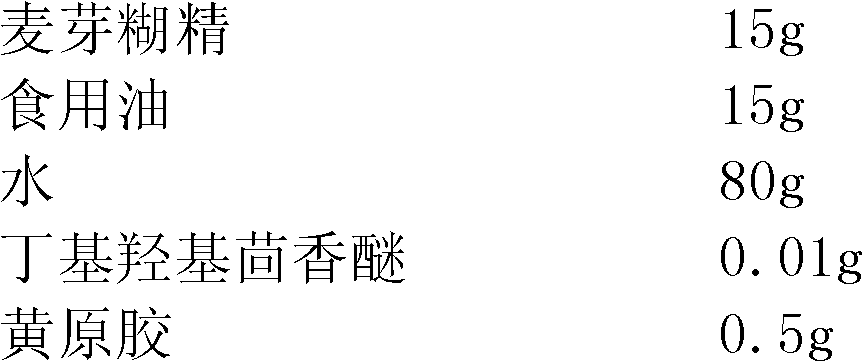

[0033] The raw materials and quality of cooking onion powder are as follows:

[0034]

[0035] The spice powder is a mixture of anise powder, prickly ash powder and cinnamon powder in a ratio of 1:1:1 by weight.

[0036] The above-mentioned cooking seasoning powder is prepared by the following method:

[0037] (1) Take 30g green onions, remove the dry leaves, wash, chop, crush them through a colloid mill, put them into a reaction kettle, add 0.1g of cellulase at the same time, stir and heat to 60°C, keep warm, and enzymatically hydrolyze for 0.5 hours to obtain Scallion enzymatic solution;

[0038] (2) Put 30g of scallion powder, 50g of concentrated onion juice, 5g of spice powder, 5g of edible oil, and 50g of water into the reaction kettle, mix with the scallion enzymatic solution, stir at the same time, airtight, heat to 120°C, and keep warm for 60 minutes;

[0039] (3) Stop heating, after cooling to 50°C, add 0.01g of BHA, 0.5g of xanthan gum, and 10g of maltodextrin, ...

Embodiment 3

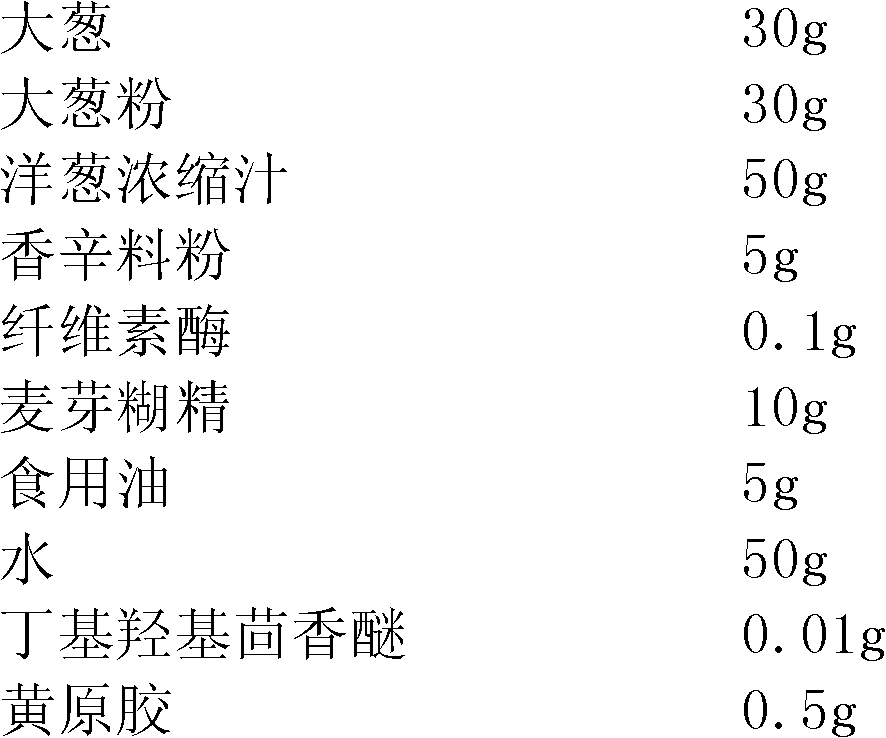

[0042] The raw materials and quality of cooking onion powder are as follows:

[0043]

[0044] The spice powder is a mixture of anise powder, prickly ash powder and cinnamon powder in a ratio of 1:1:1 by weight.

[0045] The above-mentioned cooking seasoning powder is prepared by the following method:

[0046] (1) Take 50g of scallions, remove the dried leaves, wash, chop, pulverize through a colloid mill, put them into a reaction kettle, add 0.3g of cellulase at the same time, stir and heat to 80°C, keep warm, and enzymatically hydrolyze for 2 hours to obtain Scallion enzymatic solution;

[0047] (2) Put 50g of scallion powder, 100g of concentrated onion juice, 10g of spice powder, 20g of edible oil, and 100g of water into the reaction kettle, mix with the scallion enzymatic solution, stir at the same time, airtight, heat to 130°C, and keep for 3 hours;

[0048] (3) Stop heating, after cooling to 70°C, add 0.05g of BHA, 1g of xanthan gum, and 20g of maltodextrin, stir fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com