Container automatic disinfection inspection system and its disinfection inspection method

An automatic disinfection and container technology, which is applied in the direction of disinfection, water supply equipment, sanitary equipment for toilets, etc., can solve the problems of lack of disinfection, short spraying distance, and difficult alignment, so as to improve the efficiency of disinfection operations, eliminate spraying dead ends, The effect of improving the disinfection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

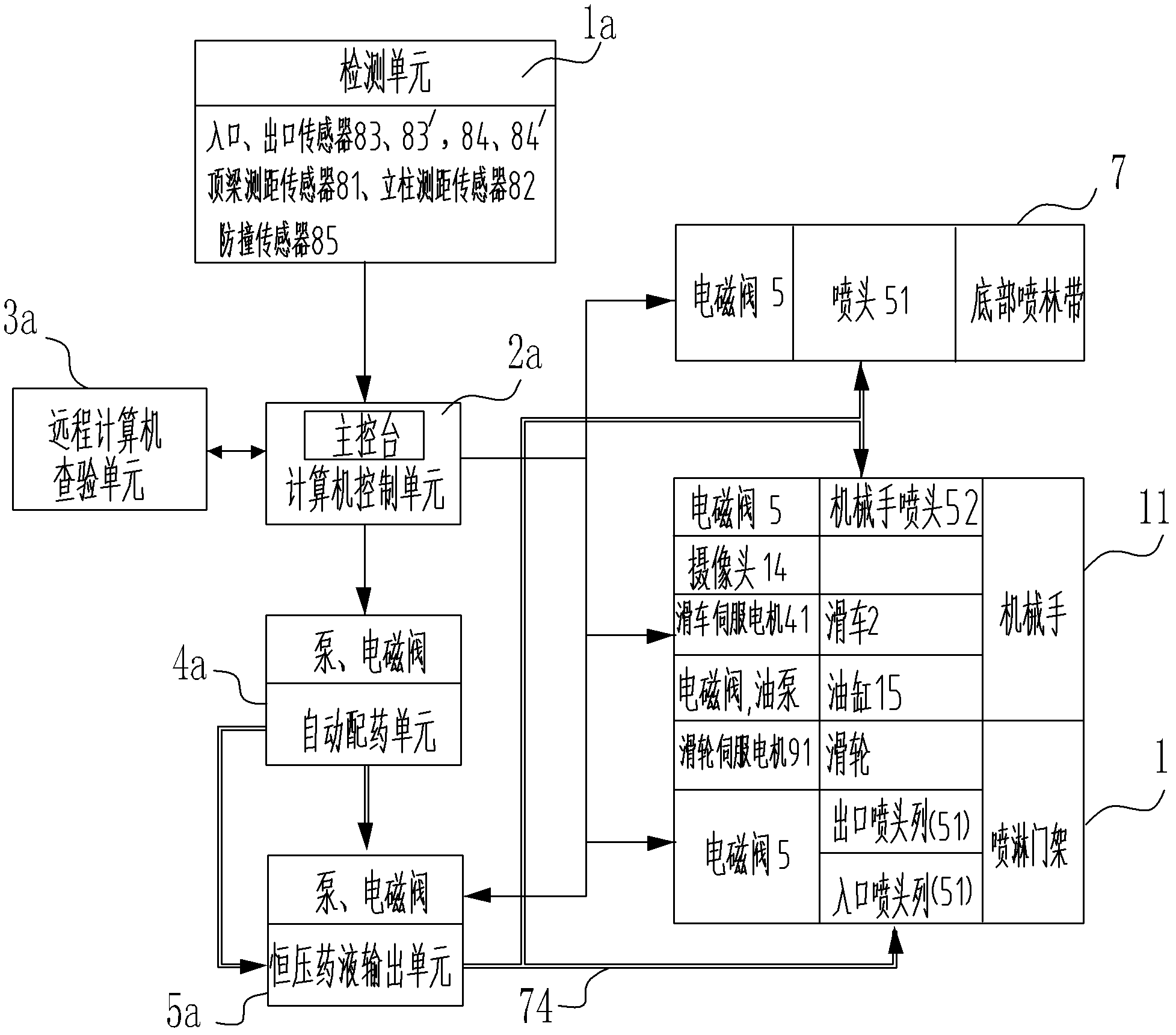

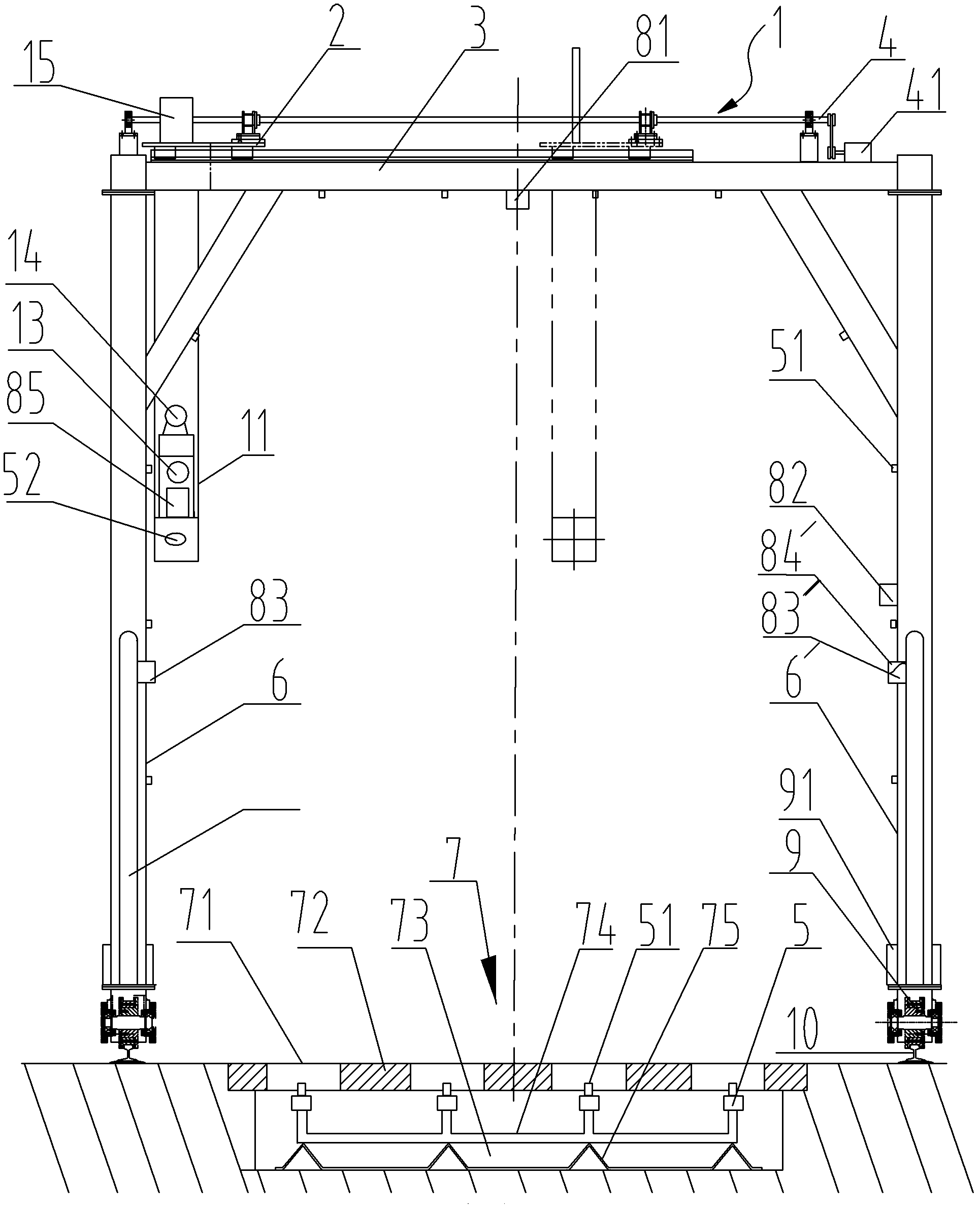

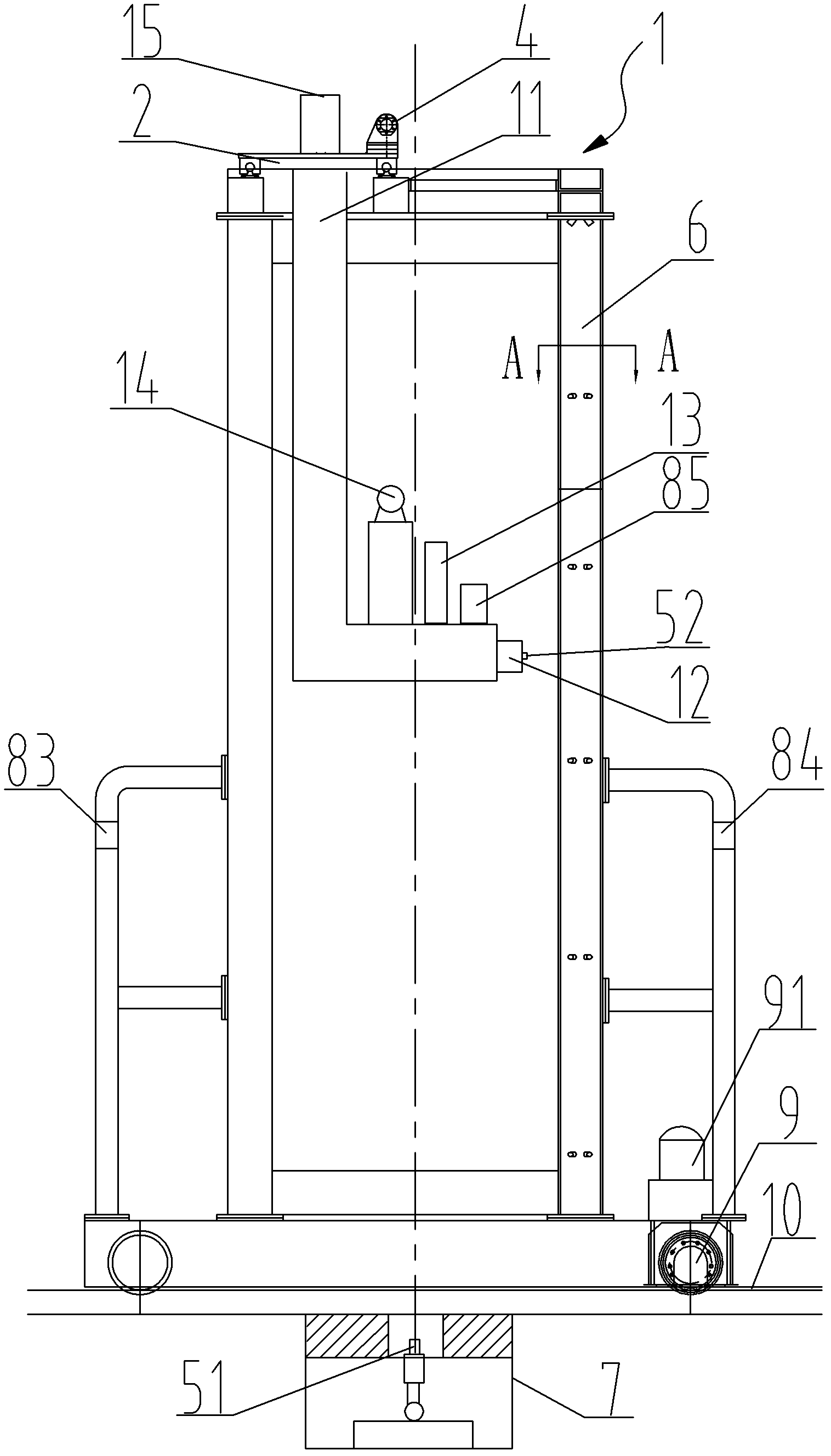

[0033] figure 1 It shows a container automatic disinfection inspection system, the single line in the figure represents the electrical connection, and the double line represents the liquid medicine pipeline connection. The system includes a computer control unit 2a equipped with a main console, an automatic dispensing unit 4a and a constant pressure liquid medicine output unit 5a, a detection unit 1a made up of a plurality of sensors, a remote computer inspection unit 3a, and a sprayer located in the disinfection channel. Shower frame 1 and manipulator 11. Each sensor of the detection unit is connected with the computer control unit, the automatic dispensing unit is connected with the nozzle 51 of the spray gantry and the nozzle 52 of the manipulator through the constant pressure medicine liquid output unit through the drug delivery tube 74, and the computer control unit is electrically connected by controlling the actuator An automatic dispensing unit 4a, a constant pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com