Flue gas wet desulfurization cooling device

A wet desulfurization and cooling device technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as blockage of primary cooling nozzles, waste of energy and waste water, and failure of primary cooling, so as to reduce construction and The effect of operating cost, reducing equipment construction cost and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

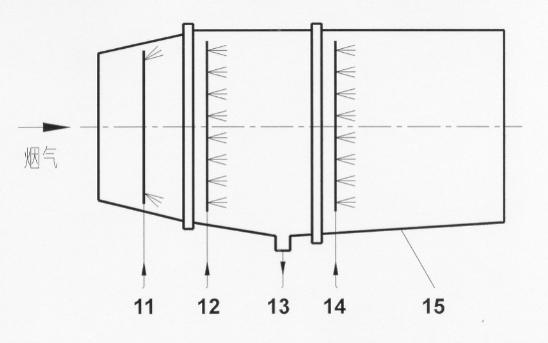

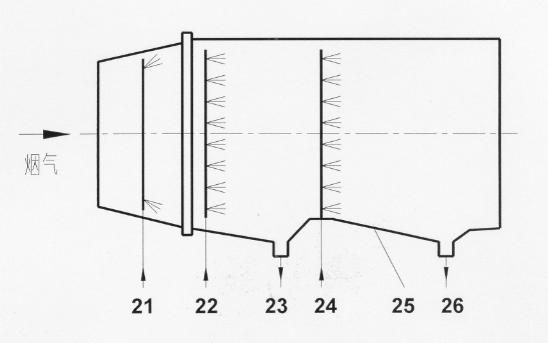

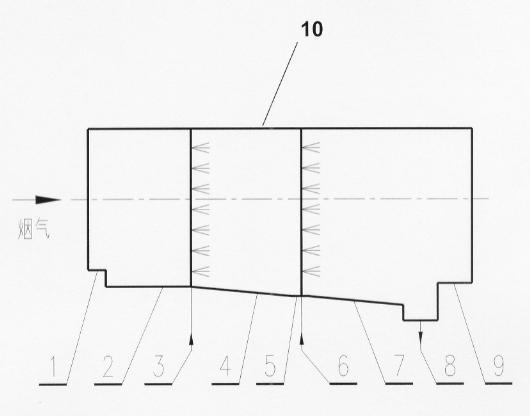

[0029] see image 3 , the present invention provides a flue gas wet desulfurization cooling device, which is mainly composed of a cylinder 10 , a primary cooling system 3 and a secondary cooling system 6 . The primary cooling system 3 and the secondary cooling system 6 are provided with only one discharge port 8 , and the discharge port 8 is provided at the rear end of the cylinder body 10 .

[0030] The primary cooling system 3 is air mist cooling, which is composed of several spray guns, which are evenly installed on the bracket, and the gas (compressed air) and liquid (process water) sources of the spray guns can enter from the upper part and both sides of the cylinder 10.

[0031] The secondary cooling system 6 is composed of several hollow cone nozzles, which are evenly installed on the support, and the cooling slurry can enter from the top of the cylinder 10, and can also enter from the bottom of the cylinder 10. In order to prevent the cooling slurry from clogging the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com