Mine-type all-steel radial truck tire tread rubber and preparation method thereof

A radial tire and tread rubber technology, applied in the field of tire tread rubber, can solve the problems of insufficient crack resistance and fracture resistance of grooves, and achieve improved crack resistance and fracture resistance, fatigue resistance, and tear resistance. The effect of crack strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

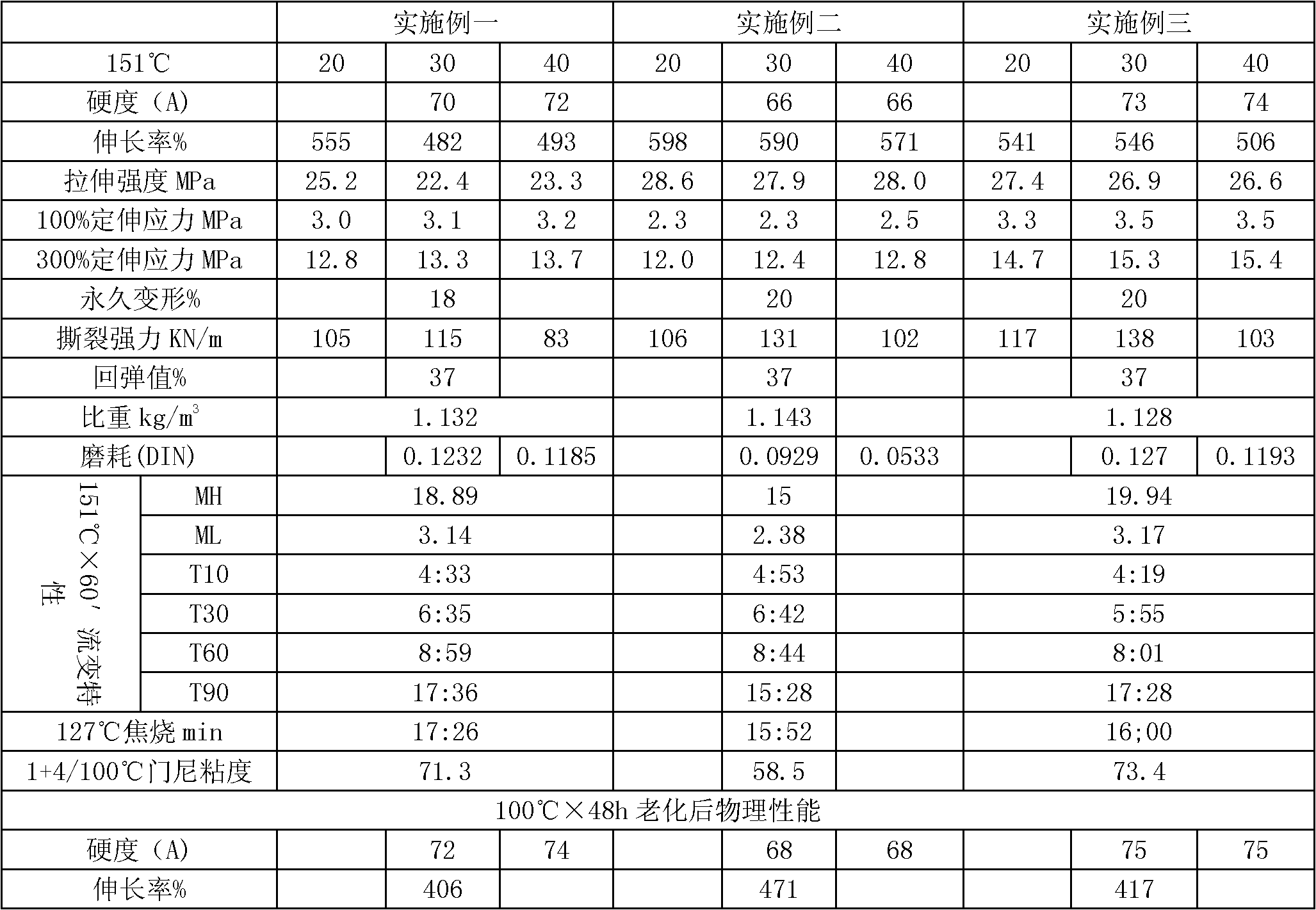

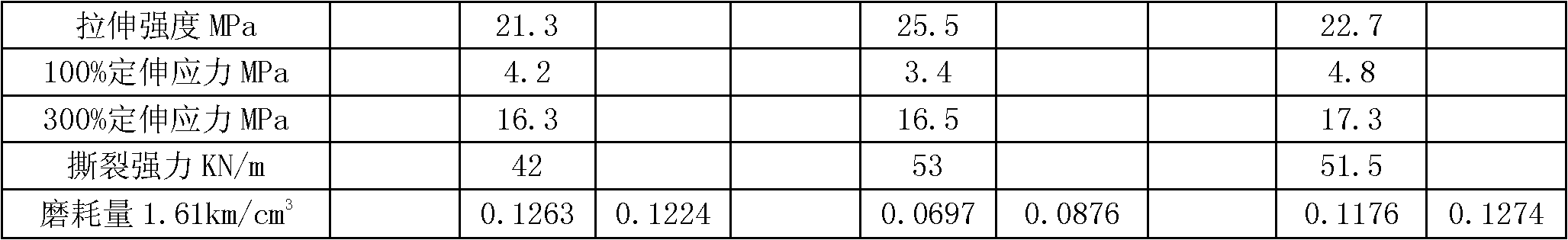

Examples

Embodiment 1

[0037] Embodiment one: a kind of preparation method of mine-type all-steel radial truck tire tread rubber comprises the following process steps:

[0038] (1) One-stage mixing: Put 70kg of natural rubber, 30kg of styrene-butadiene rubber and 0.15kg of peptizer SJ-103 in the mixing room for 10 seconds of plasticizing raw rubber, then add 18kg of N234 carbon black, 10kg white carbon black, 2kg silane coupling agent, 2.5kg zinc oxide, 1kg stearic acid, 1kg plasticizer and 1kg anti-crack resin RT260, continue mixing for 15 seconds, then add 8kg N234 carbon black to the mixing chamber for Mix for 15 seconds, and finally inject 1 kg of aromatic oil into the mixing chamber for 10 seconds of mixing. After mixing, deglue is carried out to obtain a section of masterbatch; The pressure is 5.0 Bar, the cooling circuit water temperature of the mixing chamber is 40°C, the rotor cooling circuit water temperature is 35°C, and the glue discharge temperature is 140°C;

[0039] (2) Stand still f...

Embodiment 2

[0043] Embodiment two: a kind of preparation method of mine-type all-steel radial truck tire tread rubber comprises the following process steps:

[0044] (1) One-stage mixing: put 80kg of natural rubber, 20kg of styrene-butadiene rubber and 0.1kg of peptizer SJ-103 in the mixing room for 20 seconds of plasticizing raw rubber, and then add 19kg of N234 carbon black, 15kg white carbon black, 3kg silane coupling agent, 3.5kg zinc oxide, 2kg stearic acid, 2kg plasticizer and 2kg anti-crack resin RT260, continue mixing for 20 seconds, then add 10kg N234 carbon black to the mixing chamber for Mix for 20 seconds, and finally inject 2kg of aromatic oil into the mixing chamber for mixing for 15 seconds. After mixing, perform glue removal to obtain a section of masterbatch; The pressure is 5.5 Bar, the cooling circuit water temperature of the mixing chamber is 40°C, the rotor cooling circuit water temperature is 35°C, and the debinding temperature is 150°C;

[0045] (2) Stand still for...

Embodiment 3

[0049] Embodiment three: a kind of preparation method of mine-type all-steel radial truck tire tread rubber comprises the following process steps:

[0050] (1) One-stage mixing: Put 90kg of natural rubber, 10kg of styrene-butadiene rubber and 0.2kg of peptizer SJ-103 in the mixing room for raw rubber mastication for 30 seconds, then add 23kg of N234 carbon black, 20kg white carbon black, 4kg silane coupling agent, 4.5kg zinc oxide, 3kg stearic acid, 3kg plasticizer and 3kg anti-crack resin RT260, continue mixing for 35 seconds, then add 11kg N234 carbon black to the mixing chamber for Mix for 35 seconds, and finally inject 3kg of aromatic oil into the mixing chamber for 30 seconds of mixing. After mixing, deglue is carried out to obtain a section of masterbatch; the rotor speed during the section of mixing is 45rmp. The pressure is 6.0 Bar, the cooling circuit water temperature of the mixing chamber is 40°C, the rotor cooling circuit water temperature is 35°C, and the debindin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com