Fog sealing layer material and preparation method thereof

A technology of fog sealing layer material and water-based epoxy resin, which is used in building thermal insulation materials, building components, buildings, etc. Problems such as the use of fog seal material can not be observed, and the effect of good adhesion, recovery performance and excellent wear resistance can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of mist seal material of the present invention is realized by the following steps:

[0031] Step 1: After heating and melting 20 parts by weight of asphalt and 10 parts by weight of asphalt regeneration agent, that is, tall oil pitch, mix evenly with 5 parts by weight of penetration aid, kerosene; add 1 part by weight of asphalt emulsifier to 20 parts by weight. Stir in water at 50°C in parts by weight to completely dissolve the asphalt emulsifier; then add the aqueous solution of the asphalt emulsifier and the melted mixture into a colloid mill shearer to prepare component A of the mist seal layer material.

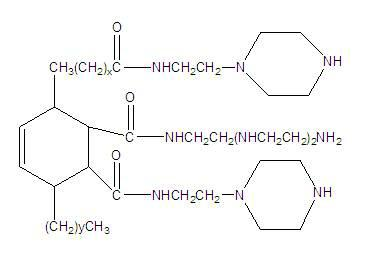

[0032] The structure of the asphalt emulsifier is

[0033]

[0034] Step 2: Mix 20 parts by weight of the water-based epoxy resin, that is, the epoxy resin E44 with an effective content of 60% after emulsification, and the water-based epoxy resin curing agent, that is, the 703 curing agent, and mix evenly, wherein the water-based epoxy r...

Embodiment 2

[0037] The preparation method of mist seal material of the present invention is realized by the following steps:

[0038] Step 1: After heating and melting 30 parts by weight of asphalt and 20 parts by weight of asphalt regenerant, namely plant asphalt, mix evenly with 10 parts by weight of permeation aid, namely diesel oil; add 10 parts by weight of asphalt emulsifier to 35 parts by weight Stir in water at 60°C to completely dissolve the asphalt emulsifier; then add the asphalt emulsifier aqueous solution and the molten mixture into the colloid mill shearer to make component A of the mist sealant material.

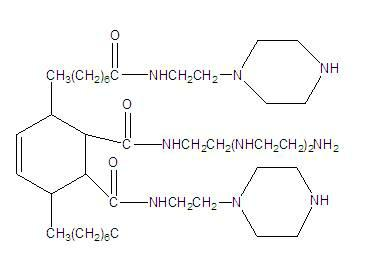

[0039] The structure of the asphalt emulsifier is

[0040]

[0041] Step 2: the water-based epoxy resin of 35 parts by weight, that is, the product obtained after emulsification of epoxy resin E44 with an effective content of 60%, and the water-based epoxy resin curing agent, that is, 120 curing agent, are mixed uniformly, wherein the water-based epoxy resin curing ag...

Embodiment 3

[0044] The preparation method of mist seal material of the present invention is realized by the following steps:

[0045] Step 1: After heating and melting 40 parts by weight of asphalt and 20 parts by weight of asphalt regenerant, i.e. rubber extraction oil, mix evenly with 15 parts by weight of penetration aid, i.e. rapeseed oil; add 10 parts by weight of asphalt emulsifier to 50 parts by weight A portion of water at 70°C, stirred to completely dissolve the bitumen emulsifier; then add the aqueous solution of the bitumen emulsifier and the melted mixture into the homogenizer to make component A of the fog seal material.

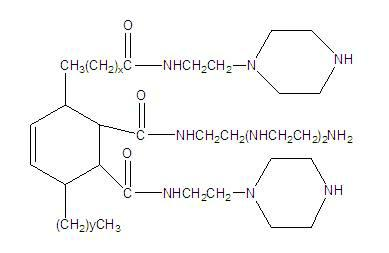

[0046] The structure of the asphalt emulsifier is

[0047]

[0048] Step 2: the water-based epoxy resin of 50 parts by weight, that is, the product obtained after emulsification of epoxy resin E44 with an effective content of 60%, and the water-based epoxy resin curing agent, that is, 120 curing agent, are mixed uniformly, wherein the water-based epoxy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com