Dyeing technology of ramie strips and manufacturing method of spinning

A production method, ramie technology, applied in dyeing, yarn, textiles and papermaking, etc., can solve problems such as broken needles and missing needles, waste, easy fiber strips to be broken, etc., to achieve increased added value, high economic benefits, and not easy to break strip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Embodiment 1: produce 24Nm pure hemp brown knitting yarn

[0078] 1. Make ramie fiber strips into coil-shaped ramie balls

[0079]

[0080] 2. Put the ramie balls into the nylon mesh bag, fix the ramie fiber strips along the axial center hole from the outside, with moderate tightness, so as to prevent the ramie fiber strips from being disordered.

[0081] 3. Put the fixed ramie balls into the hanging cage.

[0082] 4. Hang the cage with ramie balls into the yarn dyeing machine.

[0083] 5. Carry out ramie fiber strip dyeing

[0084] Dyeing process: pre-treatment → dyeing → post-treatment

[0085] ①, pre-processing

[0086]

[0087] Such a cycle not only ensures uniform dyeing, but also ensures that the fiber strips do not flocculate.

[0088] ②, dyeing

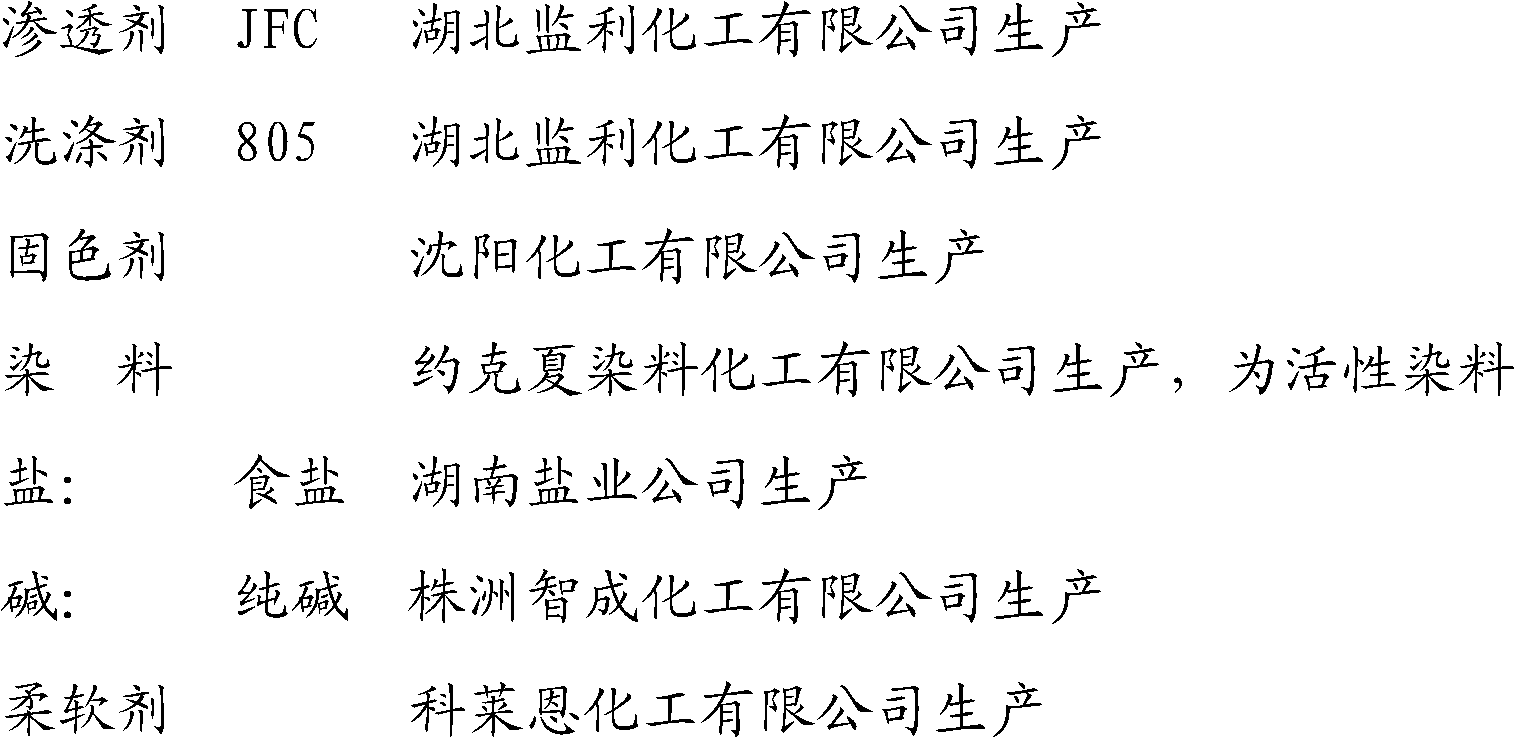

[0089] Dye: reactive dye (brown) 3BE-N: 0.63%, 3BF-N: 0.51%, B: 23%.

[0090] Bath ratio: 1:4

[0091] Add dissolved dye at room temperature, run for 5 minutes, add dissolved salt, heat up to 60°C, run for...

Embodiment 2

[0137] Embodiment 2: produce 60Nm ramie viscose hemp gray spinning yarn (30% ramie / 70% viscose)

[0138] 1, according to the method for step 1~10 of embodiment 1, ramie fiber strip is dyed into black ramie black fiber strip.

[0139] 2, according to the method for step 11~13 of embodiment 1, make combed ramie black fiber strip.

[0140] 3. Combining and drafting the combed ramie black fiber strips to make a semi-finished product that meets the technological requirements and has evenness.

[0141] Main process conditions:

[0142]

[0143] 4. Pre-combining ramie white fiber strips, combining and drawing to make a semi-finished product that meets the process requirements and is evenly dry. The main process conditions are the same as 3.

[0144]5. Pre-combining, merging, drafting and making semi-finished products that meet the technical requirements and evenly dry the viscose white fiber strips. The main process conditions are the same as in 3.

[0145] 6. Process flow of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com