Networked measuring system for rotating speeds and friction power consumption of group gas centrifuges

A measurement system and centrifuge technology, applied in electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of large signal attenuation, long measurement period, poor anti-interference ability, etc., and achieve low electromagnetic radiation interference, The effect of short measurement period and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with accompanying drawing:

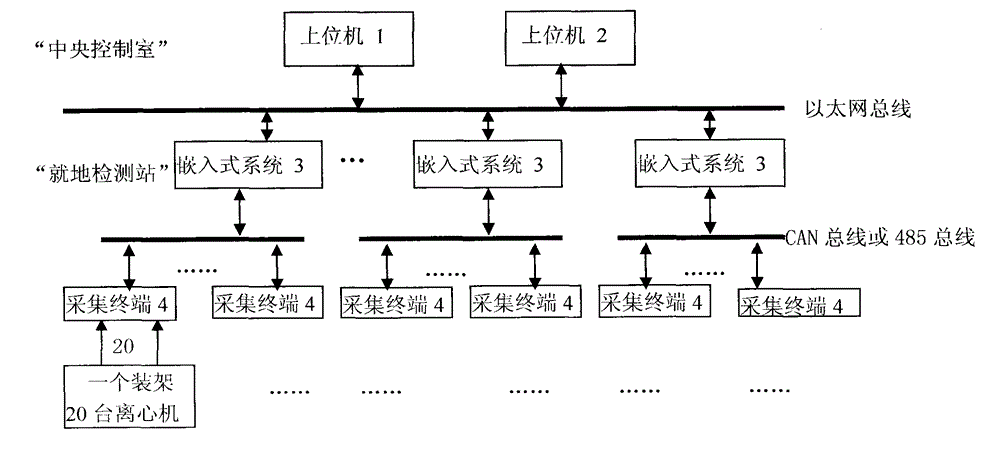

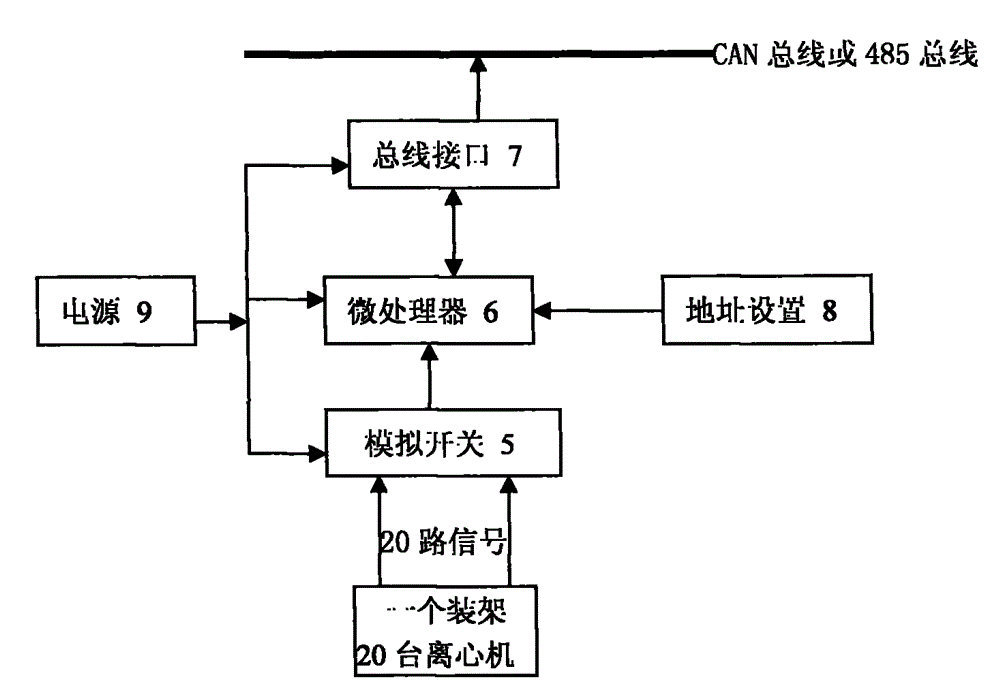

[0025] refer to figure 1 , a grouped gas centrifuge speed and friction power consumption network measurement system, including a "central control room", the first host computer 1 and the second host computer 2 of the "central control room" communicate with at least one " The embedded system 3 of the "on-site detection station" is bidirectionally connected, and the embedded system 3 of each "in-situ detection station" is bidirectionally connected with the collection terminal 4 of at least one "in-situ detection station" through the CAN bus or the 485 bus, and each The acquisition terminal 4 can collect the frequency signals of 20 centrifuges in one rack, and the acquisition terminal 4 is directly installed on the rack, the signal transmission distance is short, the anti-interference ability is strong, the installation is simple and convenient, saving space and reducing costs. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com