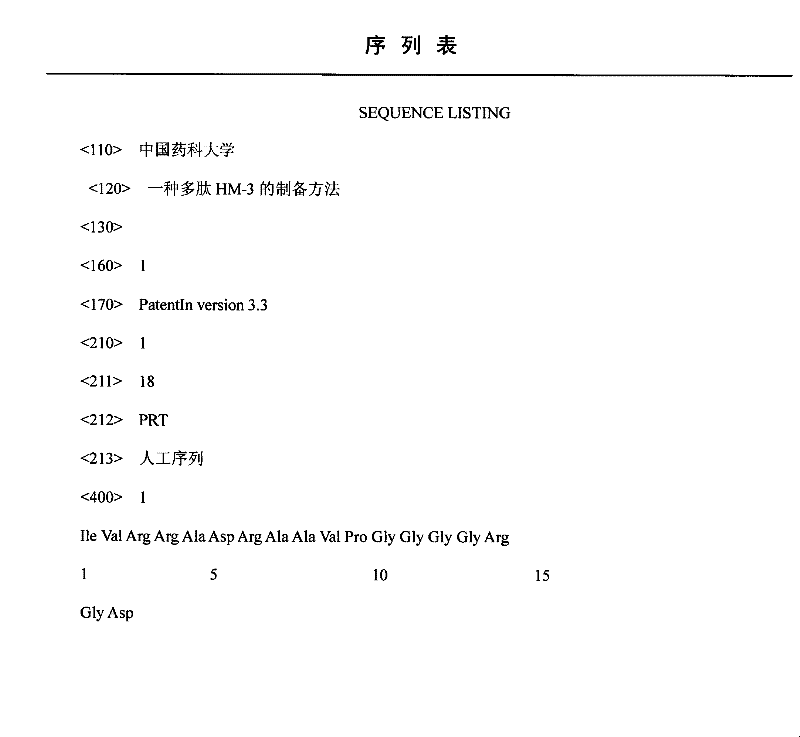

A kind of preparation method of polypeptide hm-3

A technology of HM-3 and polypeptide, applied in the field of biochemistry, can solve problems such as troublesome, time-consuming and large loss, and achieve the effect of reducing cost, reducing pollution and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Synthesis:

[0036] Weigh 14.7g of Fmoc-Asp(Otbu)-Wang resin, pour it into a 1L glass sand core reaction column, add CH 2 Cl 2 147ml to fully expand the resin.

[0037] Uncapping: Add 25ml of hexahydropyridine / DMF decapping solution, seal it and place it in a shaker for 5 minutes, the temperature is controlled at room temperature, drain the decapping solution after 5 minutes, wash with DMF once in the middle, and then add 20% 25ml of capping solution reacted for 15 minutes

[0038] Washing: drain the capping liquid, wash the resin with DMF for 6 times, drain, take 20 resins in a small test tube, add color detector, and heat at 115°C for 3 minutes.

[0039] Condensation: Weigh 2.025g of protected amino acid and HOBt, dissolve in 15ml of DMF and 2.33ml of DIC, then pour it into a reaction kettle for about 1.5 hours, and control the temperature at about 34°C.

[0040] Washing: Drain the reaction solution, wash the resin with DMF for 3 times, drain it, take 10-20 res...

Embodiment 2

[0062] 1. Synthesis:

[0063] Weigh 16.7g of Fmoc-Asp(Otbu)-CTC resin, pour it into a 1L reaction column with glass sand core, add CH 2 Cl 2 167ml to fully expand the resin.

[0064] Uncapping: Add 25ml of hexahydropyridine / DMF decapping solution, seal it and place it in a shaker for 5 minutes, the temperature is controlled at room temperature, drain the decapping solution after 5 minutes, wash with DMF once in the middle, and then add 20% 25ml of capping solution reacted for 15 minutes

[0065] Washing: drain the capping liquid, wash the resin with DMF for 6 times, drain, take 20 resins in a small test tube, add color detector, and heat at 115°C for 3 minutes.

[0066] Condensation: Weigh 4.815g of protected amino acid and HBTU, dissolve in 15ml of DMF and 2.47ml of DIEA, then pour it into a reaction kettle for about 1.5 hours, and control the temperature at about 34°C.

[0067] Washing: Drain the reaction solution, wash the resin with DMF for 3 times, drain it, take 10-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com