Non-electric CO2 Refrigeration Dehumidification Air Conditioner

A carbon dioxide, refrigeration and dehumidification technology, applied in safety devices, mining equipment, earthwork drilling and mining, etc., can solve the problems of normal supply, large consumption, high battery capacity requirements, etc., and achieve good effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

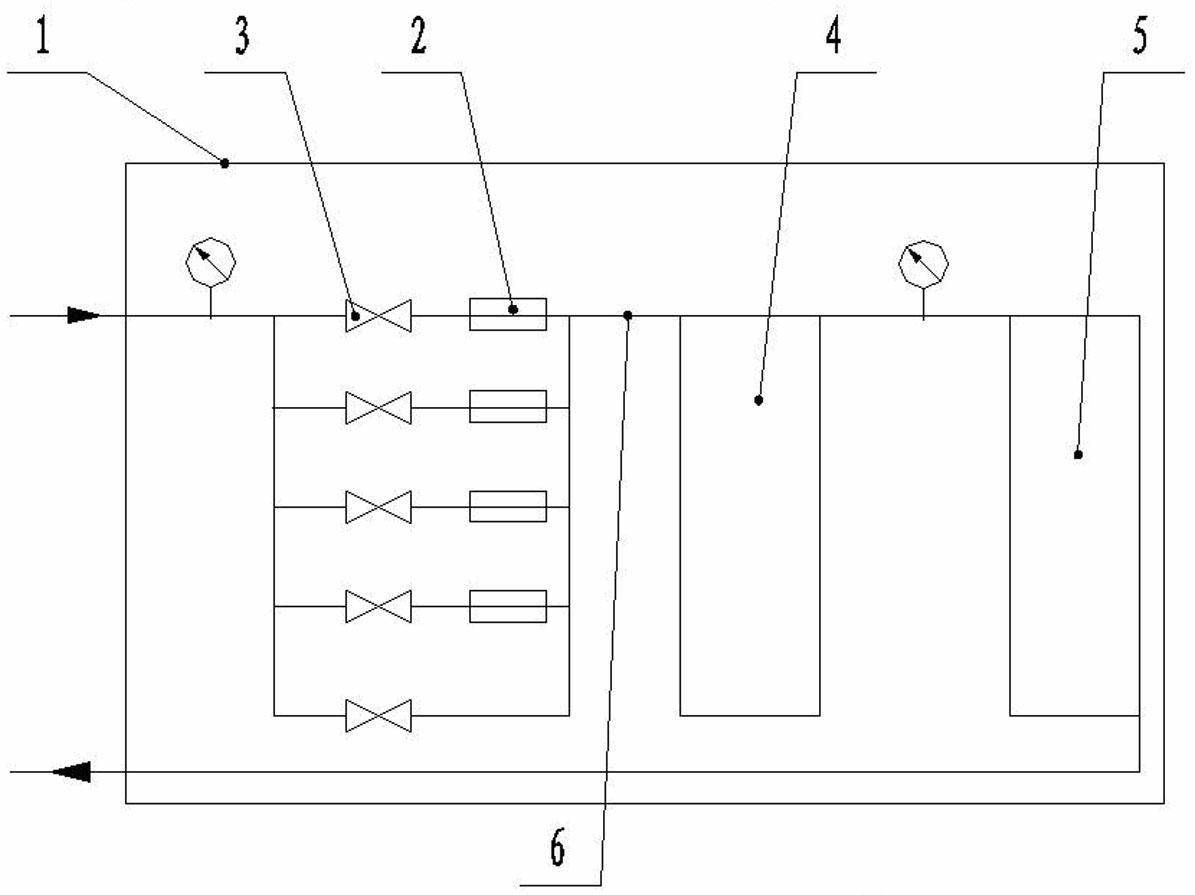

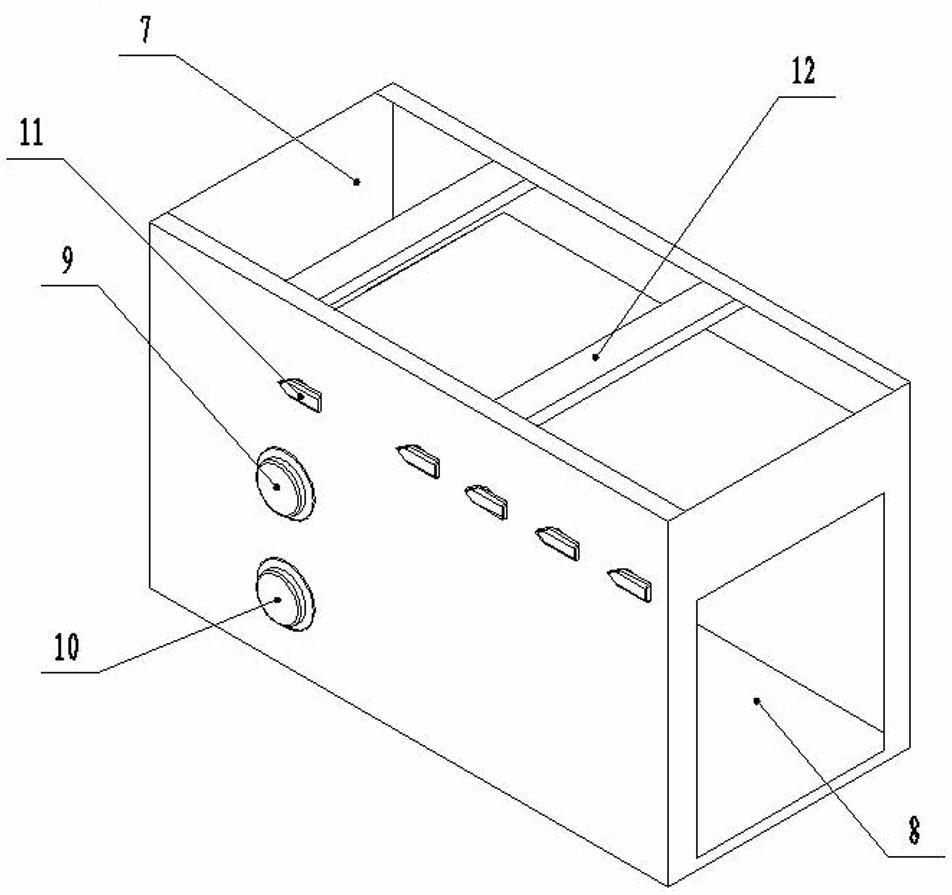

[0014] The box body 1 is assembled from panels processed from sheet metal. After the panels are processed, they are treated with corrosion resistance. The throttling pressure reducer 2 and the control valve 3 are installed on the inner side of the box body 1, the evaporator is installed at the air outlet 8, the pneumatic fan 5 is installed behind the evaporator, and the high-pressure pressure gauge 9 showing the inflow and outflow of carbon dioxide is installed on the side of the pneumatic fan 5 And low pressure gauge 10.

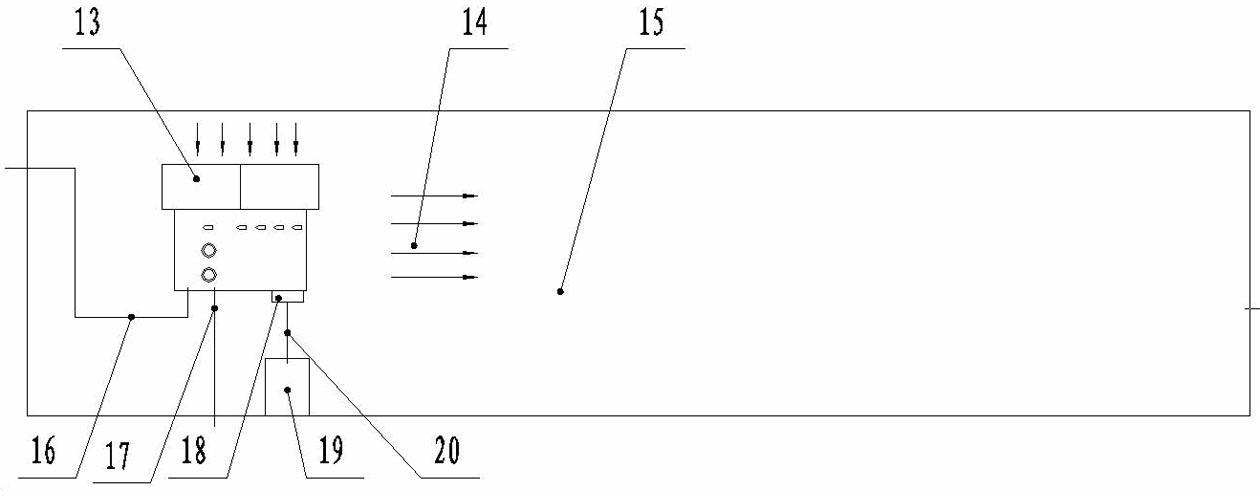

[0015] Liquid carbon dioxide enters the drier 22 from the liquid inlet thick pipe 16 and then filters out moisture therein, removes solid impurities therein through a fine mesh 23 , and then enters the elongated pipe 24 . When the liquid carbon dioxide passes through the slender tube, the pressure decreases and the flow rate increases. Due to the heat insulation of the thermal insulation material, the temperature of the liquid carbon dioxide decreases, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com