Analysis method and analysis system for gas phase combustion products of cigarettes

A technology of gas-phase combustion and analysis method, which is applied in the direction of analysis materials, material separation, measurement devices, etc., and can solve the problems of insufficient research and discussion on the formation mechanism of volatile organic compounds in flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

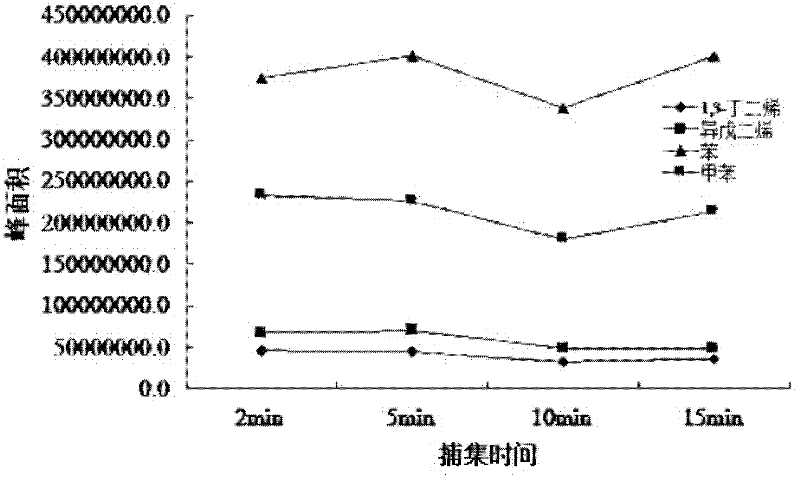

Examples

Embodiment Construction

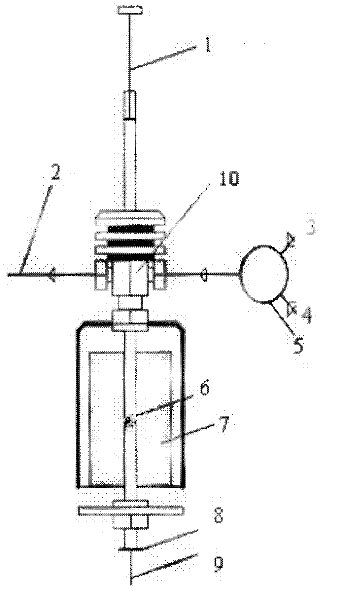

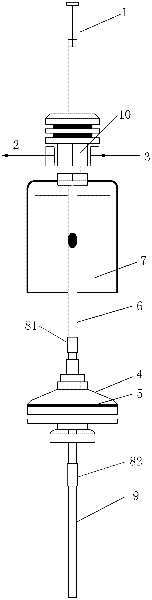

[0027] The scheme of the present invention will be further described below in conjunction with the accompanying drawings.

[0028] Such as figure 2 As shown, the analysis system of the cigarette gas phase combustion product of the present invention comprises a cracker and a thermal desorption-mass chromatography spectrometer equipped with a special thick liquid film capillary chromatographic column for volatile organic compounds (VOC) combined with the cracker (ATD-GC / MS), the cracker main body adopts SGE micro-furnace cracker (PyrojectorII), it has been transformed, and it comprises injector, air inlet chamber 10, cracking furnace chamber 7, quartz tube 6, inlet The sampler includes a sampling rod 1, which is connected to one end of the quartz tube 6 after passing through the air inlet chamber 10, the quartz tube 6 is located in the cracking furnace chamber 7, and the other end of the quartz tube 6 extends out of the cracking furnace chamber 7. Connected with the inlet of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com