A kind of manufacturing method of no fishy smell Luo Han Guo compound plant drink

A technology of plant beverage and Luo Han Guo, which is applied in the field of food processing, can solve the problems of absorption and loss of nutrients, and achieve the effect of ensuring purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

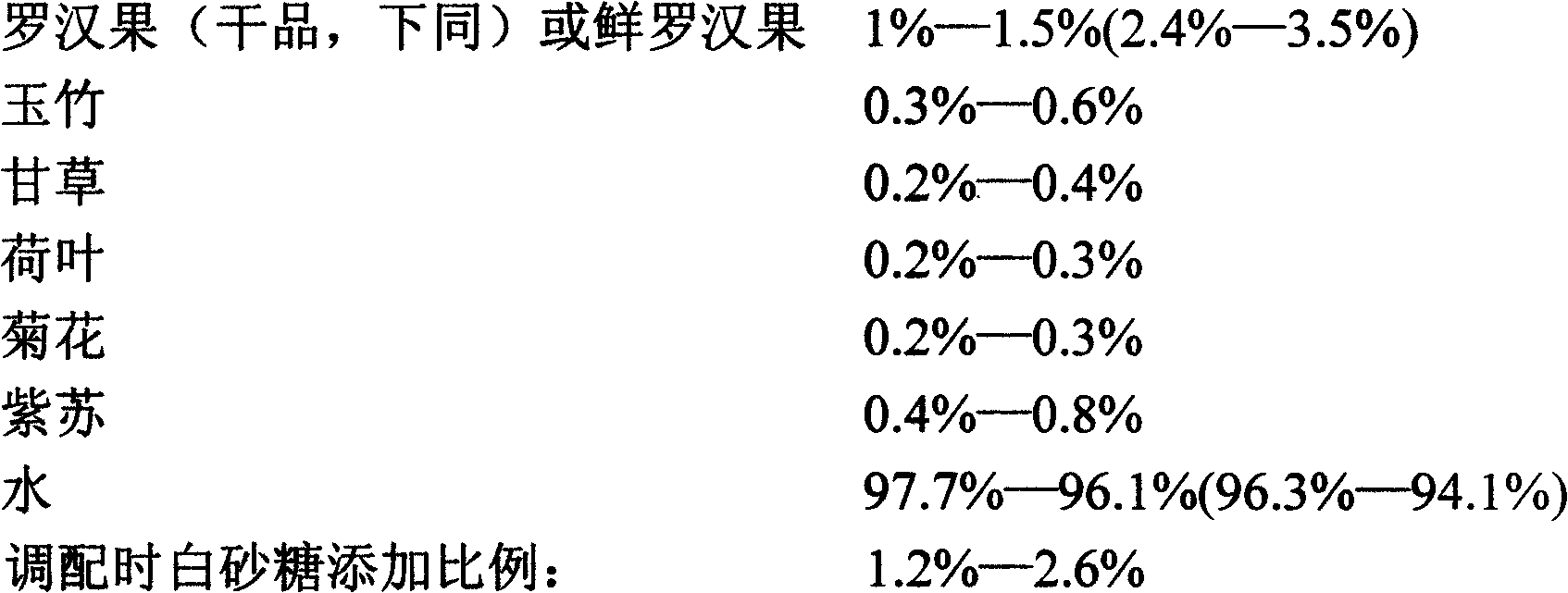

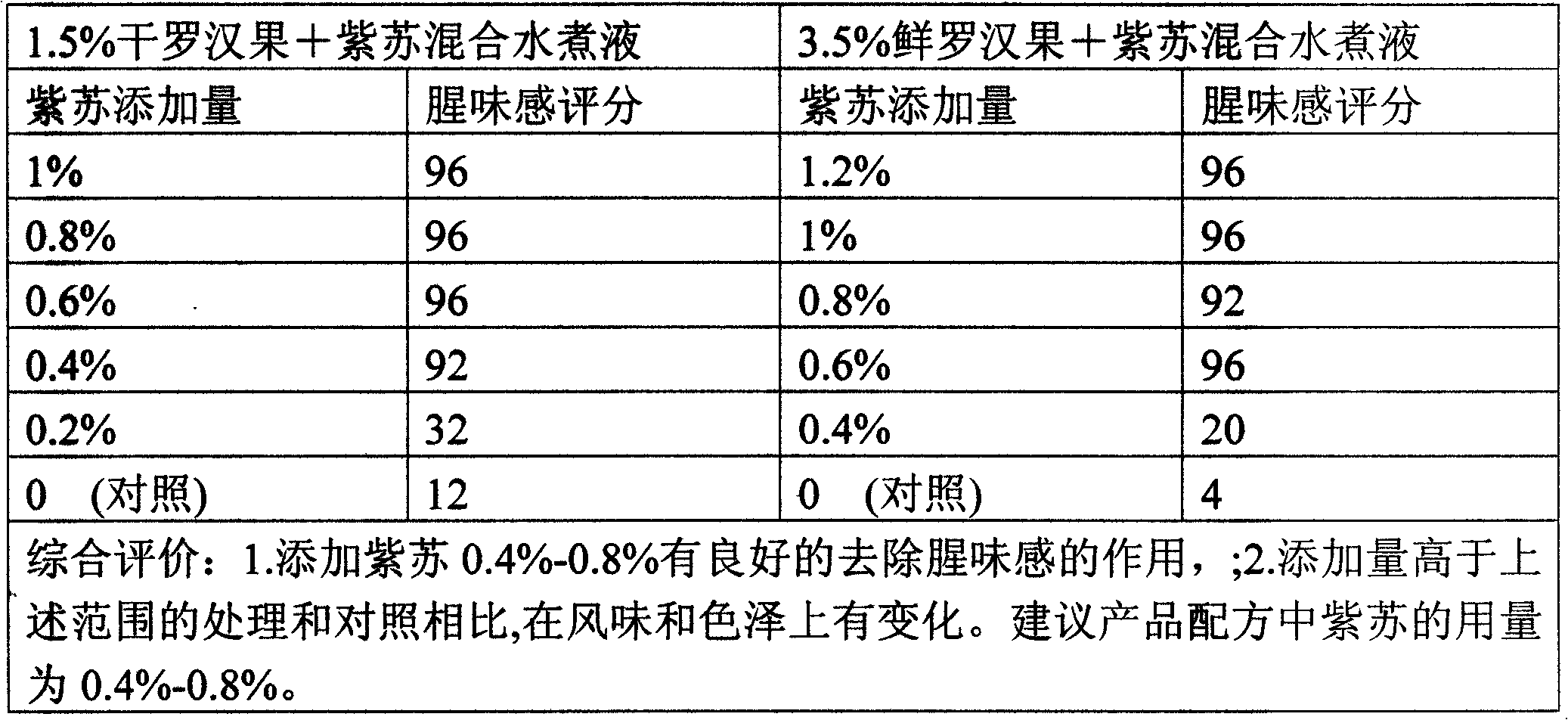

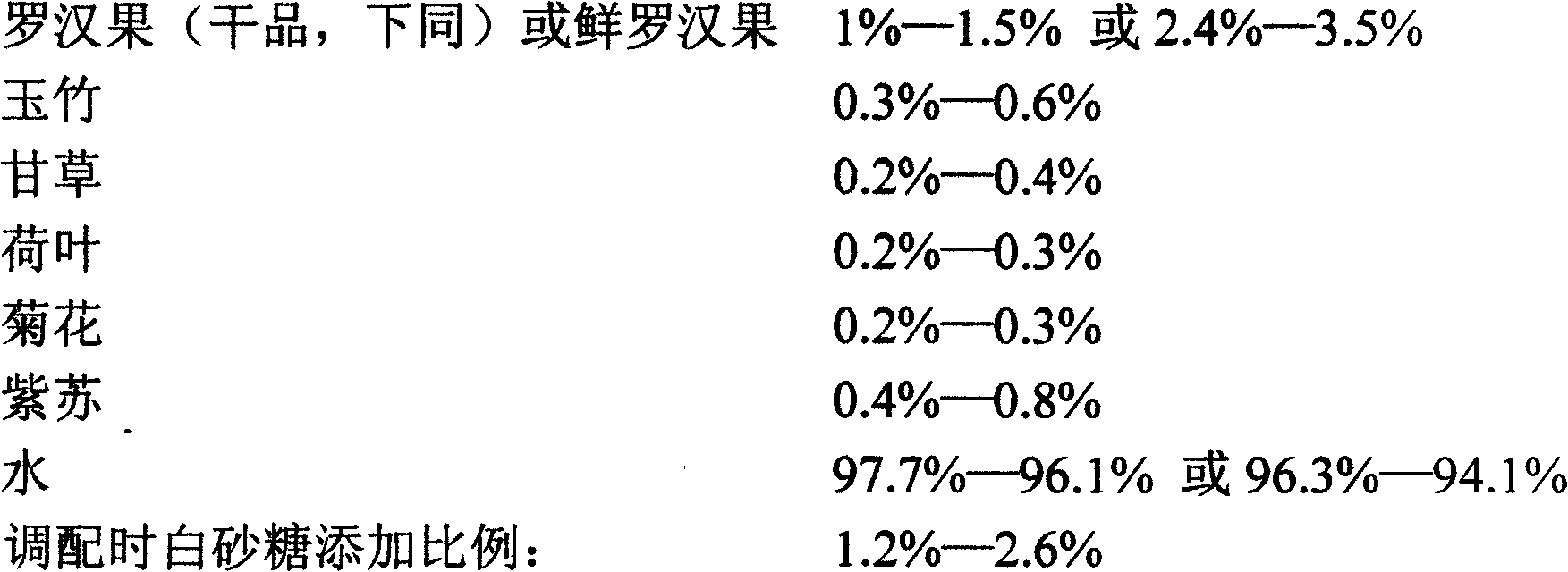

Method used

Image

Examples

example 1

[0031] Crush 12 kg of Luo Han Guo (dry product, the same below) in batches with a screw press or a homemade wooden clamp crusher. The seeds are required to be in a single separated shape, and 3 kg of 2mm-3mm segments of polygonatum, 3 kg of 2.5mm Left and right thick sliced licorice, 2 kg 2cm 2 -5cm 2 Large and small lotus leaves, 2 kg of blooming chrysanthemums, 5 kg of perilla chopped to 3mm-5mm, put them into a stainless steel tank and soak in double water for 2 hours, pour into the hanging basket of the extraction tank, add water to 1000L, Boil for 20 minutes and raise the hanging basket to obtain about 880L of extract. Discharge the slag in the hanging basket into a 300L jacketed pot, add 150L of water, boil it, keep it for 15 minutes, and perform secondary extraction. After the slag is separated, the secondary extraction liquid is sent to the extraction tank to make the total amount of extraction liquid reach 1000L , Filtered through a double filter with 5 micron pore s...

example 2

[0033] Crush 30 kg of fresh Luo Han Guo in batches with a screw press or a self-made wooden clamp crusher. The seeds are required to be in a single separated shape, and 3 kg of 2mm-3mm small pieces of polygonatum (dry product, the same below), 3 kg of 2.5 Flake licorice with a thickness of about mm, 2 kg 2 cm 2 -5cm 2 Large and small lotus leaves, 2 kilograms of blooming chrysanthemums, 5 kilograms of perilla chopped to 3mm-5mm, put them in a stainless steel tank and soak in double water for 2 hours, pour into the hanging basket of the extraction tank, and add water to 1000L , Boil for 20 minutes and raise the hanging basket to get about 830L of extract. Drain the slag in the hanging basket into a 300L jacketed pot, add 200L of water, boil it, keep it warm for 15 minutes, and perform secondary extraction. After the slag is separated, the secondary extraction liquid is sent to the extraction tank to make the total amount of extraction liquid reach 1000L , Filtered through a doub...

example 3

[0035] The process formula is basically the same as in Example 1 or Example 2, except that the 1000L of the mixture obtained after two extractions is filtered, pumped into the precipitation tower, cooled and settled for 48 hours, after removing the precipitate, it enters the blending process. The obtained product does not produce precipitation and is stable for a long time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com