Calcium 1-phosphonate-uracil mixed solution and its preparation method and application

A technology of uracil and calcium phosphonate, which is applied in the field of 1-calcium phosphonate-uracil mixture and its preparation and application, can solve problems such as gaps, affecting the quality of agricultural products, and nonconformity, so as to improve yield and quality, improve Safety, the effect of protecting the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

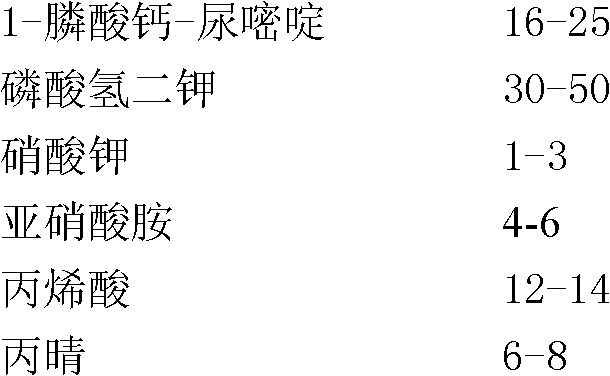

[0017] Embodiment 1: 1-calcium phosphonate-uracil mixed solution, it is mainly made up of the component of following weight ratio:

[0018]

[0019] The preparation method of 1-calcium phosphonate-uracil mixed solution, it comprises the following steps:

[0020] A. Mix 48g of dipotassium hydrogen phosphate with 300ml of water and 12ml of 85% phosphoric acid to make a phosphoric acid working solution, and control the pH value of the phosphoric acid working solution at 5.9;

[0021] B. Add water to 12g of uracil to 4000ml to obtain a uracil solution, add water to 70mg of creatine phosphokinase to 100ml to obtain a creatine phosphokinase solution, add the phosphate working solution and creatine phosphokinase solution to the uracil solution, and then obtain The mixed solution was put into a flask, and then the flask containing the mixed solution was placed in a constant temperature water tank at 37°C, stirred at a speed of 130 rpm for 50 minutes, then stirred at a speed of 100 ...

Embodiment 2

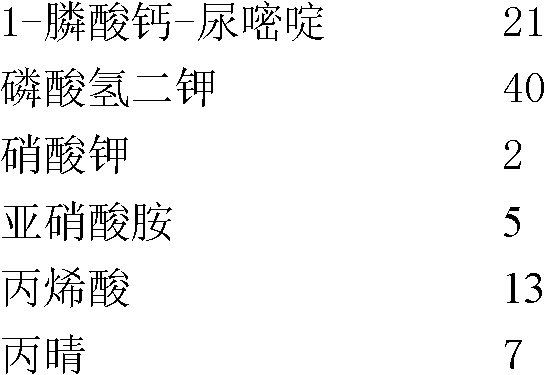

[0025] Embodiment 2: 1-calcium phosphonate-uracil mixed solution, it is mainly made up of the component of following weight ratio:

[0026]

[0027] The preparation method of 1-calcium phosphate-uracil mixed solution, it comprises the following steps:

[0028] A. Mix 55g of dipotassium hydrogen phosphate with 300ml of water and 13ml of 85% phosphoric acid to make a phosphoric acid working solution, and control the pH value of the phosphoric acid working solution at 6.0;

[0029] B. Add water to 15g of uracil to 4000ml to obtain a uracil solution, add 80mg of creatine phosphokinase to 100ml of water to obtain a creatine phosphokinase solution, add the phosphate working solution and creatine phosphokinase solution to the uracil solution, and then obtain The mixed solution was put into a flask, and then the flask containing the mixed solution was placed in a constant temperature water tank at 38°C, stirred at a speed of 135 rpm for 40 minutes, then stirred at a speed of 110 rp...

Embodiment 3

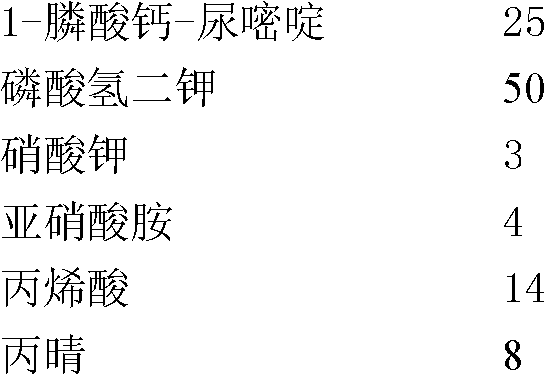

[0033] Embodiment 3: 1-calcium phosphonate-uracil mixed solution, it is mainly made up of the component of following weight ratio:

[0034]

[0035] The preparation method of 1-calcium phosphonate-uracil mixed solution, it comprises the following steps:

[0036] A. Mix 40g of dipotassium hydrogen phosphate with 300ml of water and 10ml of 85% phosphoric acid to make a phosphoric acid working solution, and control the pH value of the phosphoric acid working solution at 5.8;

[0037] B. Add water to 10 g of uracil to 4000 ml to obtain a uracil solution, add 60 mg of creatine phosphokinase to 100 ml of water to obtain a creatine phosphokinase solution, add the phosphate working solution and creatine phosphokinase solution to the uracil solution, and then obtain The mixed solution was put into a flask, and then the flask containing the mixed solution was placed in a constant temperature water tank at 36°C, stirred at a speed of 125 rpm for 60 minutes, then stirred at a speed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com