A method for obtaining yeast strains tolerant to multiple inhibitors

A technology for yeast strains and inhibitors is applied in the field of obtaining yeast strains tolerant to multiple inhibitors, which can solve the problems of increased cost, obvious inhibition effect, environmental sensitivity of inhibitors, etc., to improve tolerance, promote industrial production, The effect of stable growth traits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

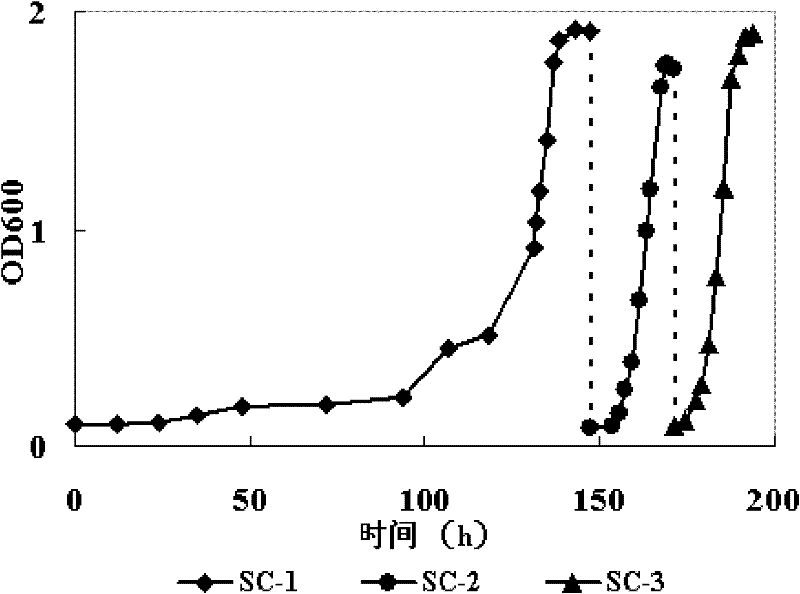

[0024] A method for obtaining yeast strains resistant to multiple inhibitors (using Angelica (SC) as the starting bacterium to obtain tolerant bacteria by subculture in a low-sugar medium containing cellulose hydrolyzate inhibitors), comprising the steps of:

[0025] 1. Preparation of seed medium and subculture medium

[0026] Seed medium: glucose 20g / L, peptone 20g / L, yeast powder 10g / L, sterilized at 121°C for 20min.

[0027] Subculture medium: glucose 20g / L, peptone 20g / L, yeast powder 10g / L, sterilized at 121°C for 20min, adding cellulose hydrolyzate inhibitors furfural, phenol and acetic acid before inoculation, so that the content of furfural was 1.3g / L L, the content of acetic acid is 5.3g / L, and the content of phenol is 0.5g / L.

[0028] 2. Subculture

[0029] Angel yeast was inoculated in 100mL seed medium and cultured at 30°C and 150rpm for 10h. then by OD 600 The initial cell concentration of =0.1 was inoculated in a fermenter containing 3L subculture medium, cul...

Embodiment 2

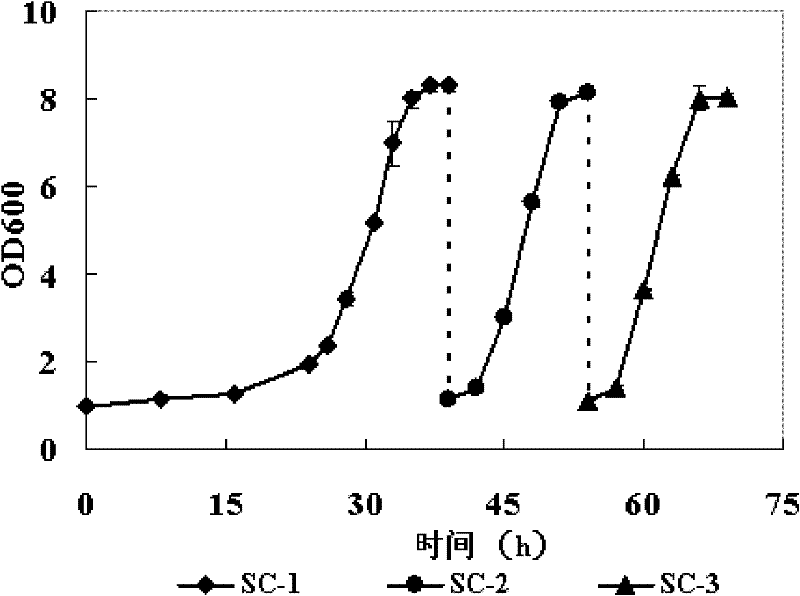

[0035] A method for obtaining yeast strains resistant to multiple inhibitors (taking Angelia yeast as the starting bacterium and utilizing subculture to obtain tolerant bacteria in a high-sugar medium containing cellulose hydrolyzate inhibitors), comprising the following steps:

[0036] 1. Preparation of seed medium and subculture medium

[0037] Seed medium: glucose 20g / L, peptone 20g / L, yeast powder 10g / L, sterilized at 121°C for 20min.

[0038] Subculture medium 1: Glucose 100g / L, peptone 20g / L, yeast powder 10g / L, sterilized at 121°C for 20min, adding cellulose hydrolyzate inhibitors furfural, phenol and acetic acid before inoculation, so that the content of furfural was 1.04g / L, the content of acetic acid is 4.24g / L, and the content of phenol is 0.4g / L.

[0039] Subculture medium 2: Glucose 100g / L, peptone 20g / L, yeast powder 10g / L, sterilized at 121°C for 20min, inhibitors of cellulose hydrolyzate inhibitors furfural, phenol and acetic acid were added before inoculatio...

Embodiment 3

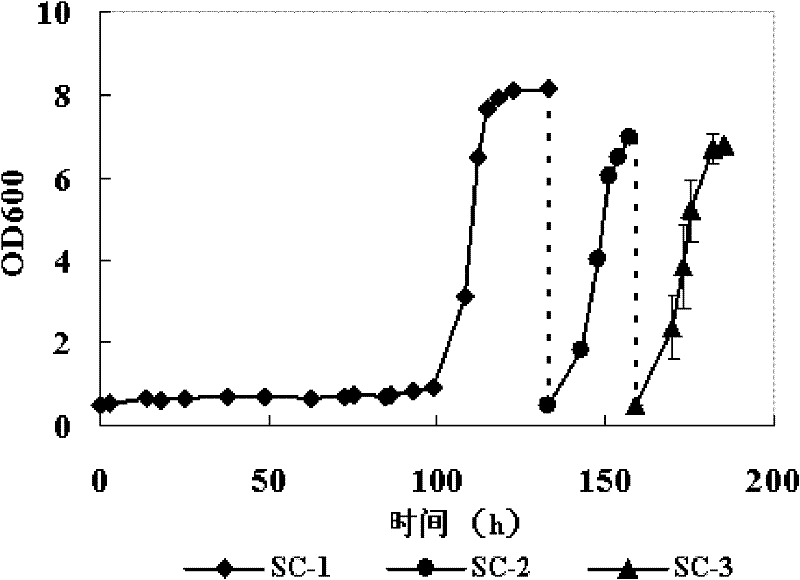

[0049] A method for obtaining yeast strains resistant to multiple inhibitors (using Saccharomyces cerevisiae BY4741 as the starting bacterium to obtain tolerant bacteria by subculture in a low-sugar medium containing cellulose hydrolyzate inhibitors), comprising the following steps:

[0050] 1. Preparation of seed medium and subculture medium

[0051] Seed medium: glucose 20g / L, peptone 20g / L, yeast powder 10g / L, sterilized at 121°C for 20min.

[0052] Subculture medium: glucose 20g / L, peptone 20g / L, yeast powder 10g / L, sterilized at 121°C for 20min, before inoculation, add cellulose hydrolyzate inhibitors: furfural, phenol and acetic acid, so that the content of furfural is 1.04g / L, the content of acetic acid is 4.24g / L and the content of phenol is 0.4g / L.

[0053] 2. Subculture

[0054] Saccharomyces cerevisiae BY4741 was cultured in 250 mL of 100 mL seed medium at 30° C. and 150 rpm for 10 h. then by OD 600 The initial cell concentration of =0.1 was inoculated in a 250...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com