Ribbon machine condition collector

A ribbon loom and collector technology, applied in the field of weaving industry, can solve the problems of large consumables, misoperation, delay, etc., and achieve the effect of optimizing production process, reducing consumption and waste, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

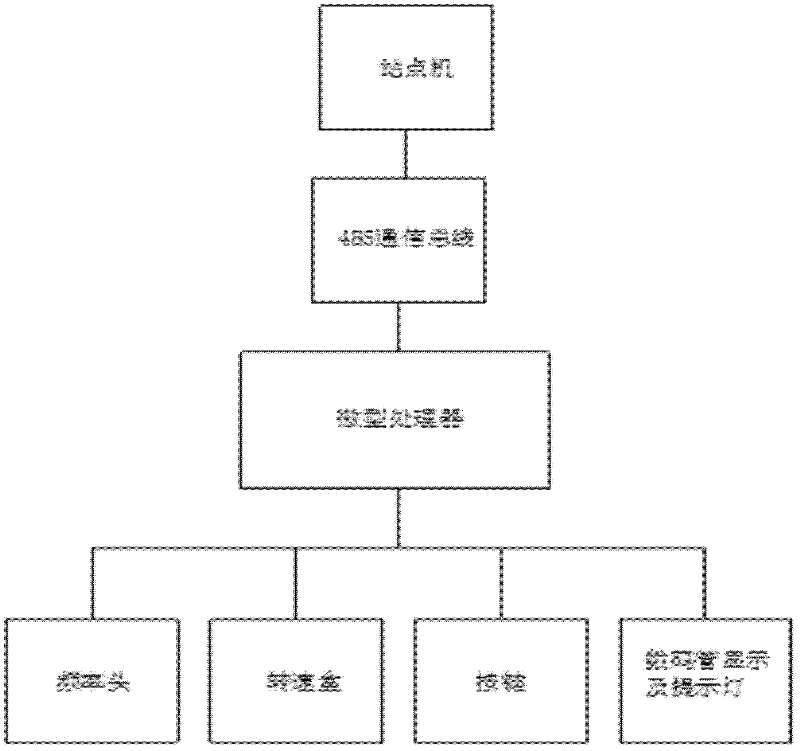

[0027] Such as figure 1 The ribbon loom working condition collector shown is connected by the station computer and the single-board computer through the RS485 communication bus; the ribbon loom working condition collector includes a single-board computer, a frequency measuring instrument, a rotational speed measuring instrument, buttons, and a digital display tube and prompt light; the single board computer collects the working condition data of the loom by measuring the swing frequency of the weaving shuttle and the rotational speed of the motor roller, and calculates and processes the data to obtain the longitude and latitude values of the loom , displayed on the digital display tube, and then transmitted to the station computer through the RS485 communication bus, and the station computer feedbacks and analyzes the webbing data through software.

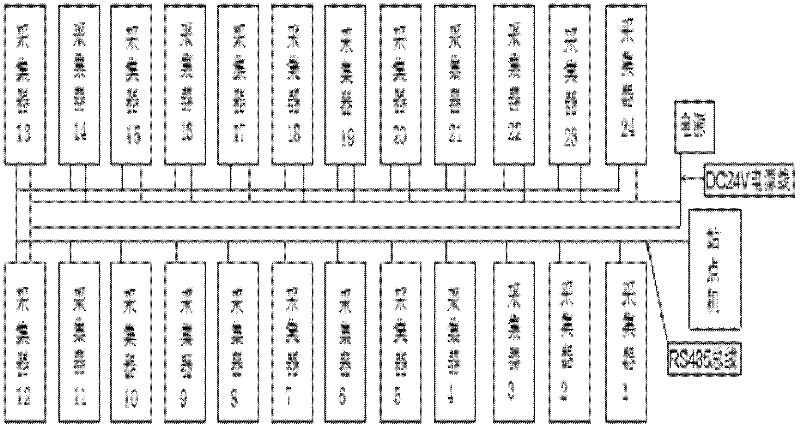

[0028] figure 2 Shown is the installation diagram of the device of the present invention. Multiple single-board computers a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com