Emergency stopping system of continuous annealing production line and control method

A production line and annealing technology, which is applied in the field of emergency shutdown system and its control, can solve problems such as increased capital investment, steel pile accidents, broken belts, etc., and achieve the effects of reliable emergency shutdown protection, improved safety level, and increased redundant communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below, the present invention will be further described in conjunction with the accompanying drawings.

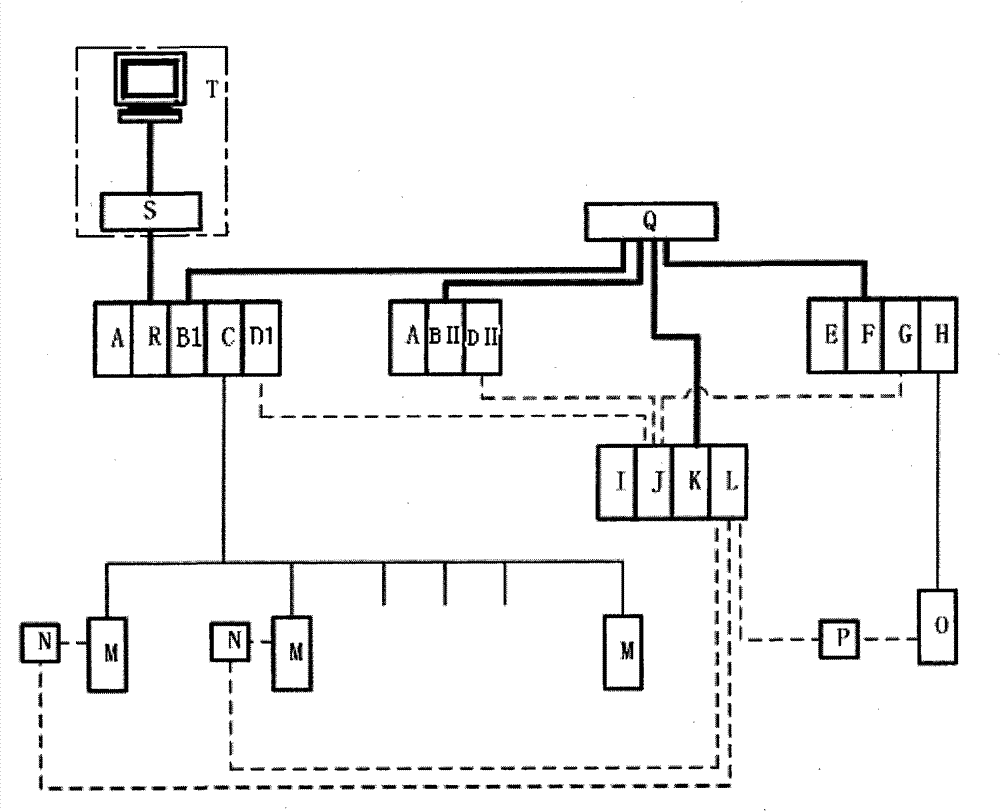

[0023] As can be seen from the accompanying drawings, the present invention mainly includes a man-machine interface T, a data exchange S, an Alstom full-line transmission control system high-speed processor A, a Siemens high-speed processor E, a Pierce emergency stop central processor I, a frequency converter M, a hydraulic emergency Stop relay P and Siemens fieldbus network remote input and output substation O, and the Ethernet switch Q added later, multiple transmission emergency stop relays N, hard-wired cables I and hard-wired cables II. Simultaneously, the present invention also correspondingly increases some modules in the three processors of Alstom, Siemens and Pierce, namely Alstom Ethernet communication module BI and BII, Alstom digital quantity output module DI, DII, Alstom Ethernet communication module R, Siemens Ethernet communication module F, Siemens dig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com