Embedded circuit board and manufacturing method thereof

A circuit board and embedded technology, applied in the direction of circuit, printed circuit, printed circuit, etc., can solve the problems of high processing difficulty, low BT heat dissipation coefficient, and inability to provide heat dissipation effect, etc., and achieve the goal of reducing processing difficulty and high heat dissipation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

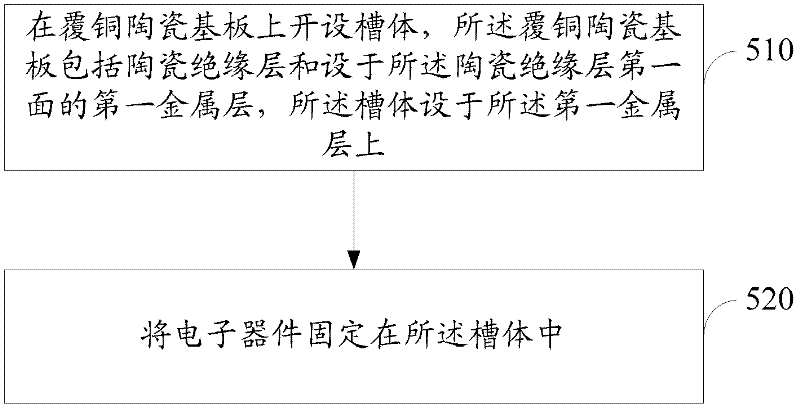

[0016] An embodiment of the present invention provides an embedded circuit board. The copper-clad ceramic base circuit board has high heat dissipation performance and low processing difficulty. Embodiments of the present invention also provide corresponding manufacturing methods. Each will be described in detail below.

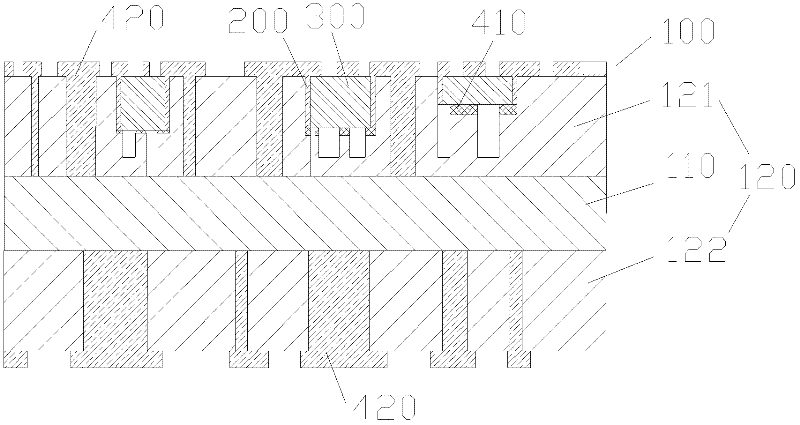

[0017] Please refer to figure 1 , an embodiment of the present invention provides an embedded circuit board, including:

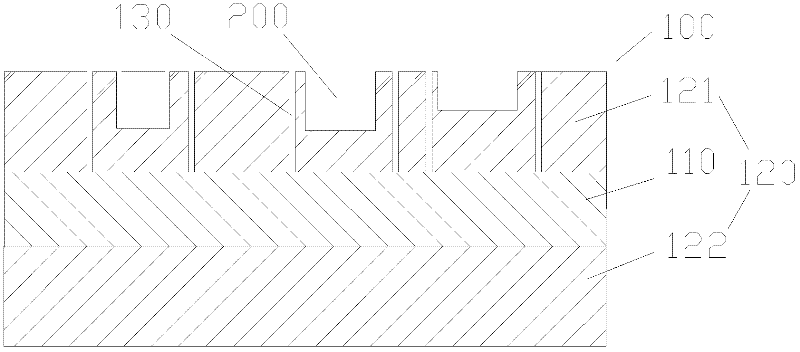

[0018] The copper-clad ceramic substrate 100 , the tank body 200 set on the copper-clad ceramic substrate 100 , and the electronic device 300 fixed in the tank body 200 .

[0019] The copper-clad ceramic substrate 100 may be a single-sided copper-clad laminate or a double-sided copper-clad laminate, including a ceramic insulating layer 110 and a metal layer 120 disposed on at least one surface of the ceramic insulating layer 110 . If it is a double-sided copper clad laminate, the metal layer 120 includes: a first metal layer 121 disposed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com