Curable silicone rubber composition

A silicone rubber composition, silicon bonding technology, applied in the direction of thin material handling, transportation and packaging, coating, etc., can solve the problem of unsatisfactory surface release properties of cured materials, and achieve excellent formability and processing characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

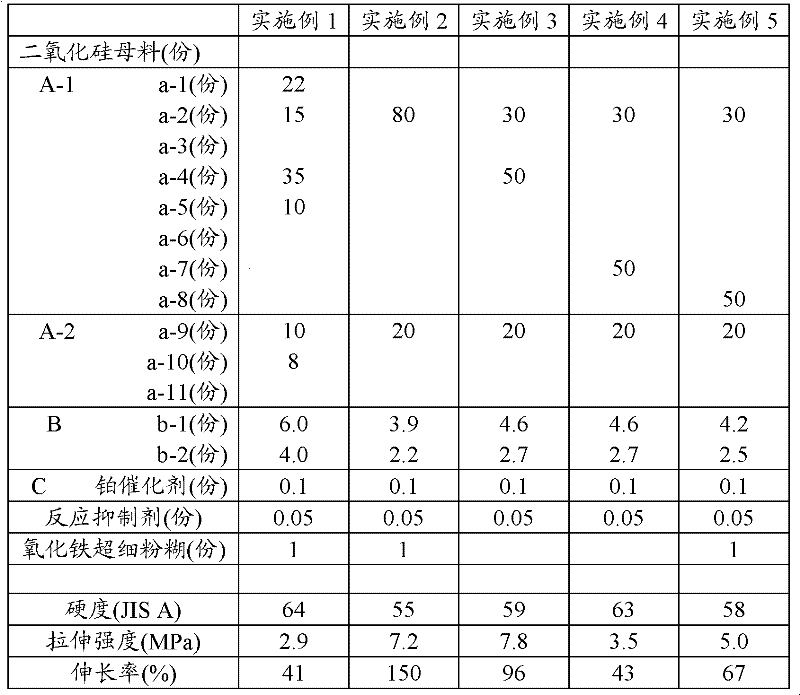

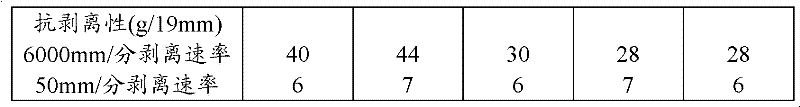

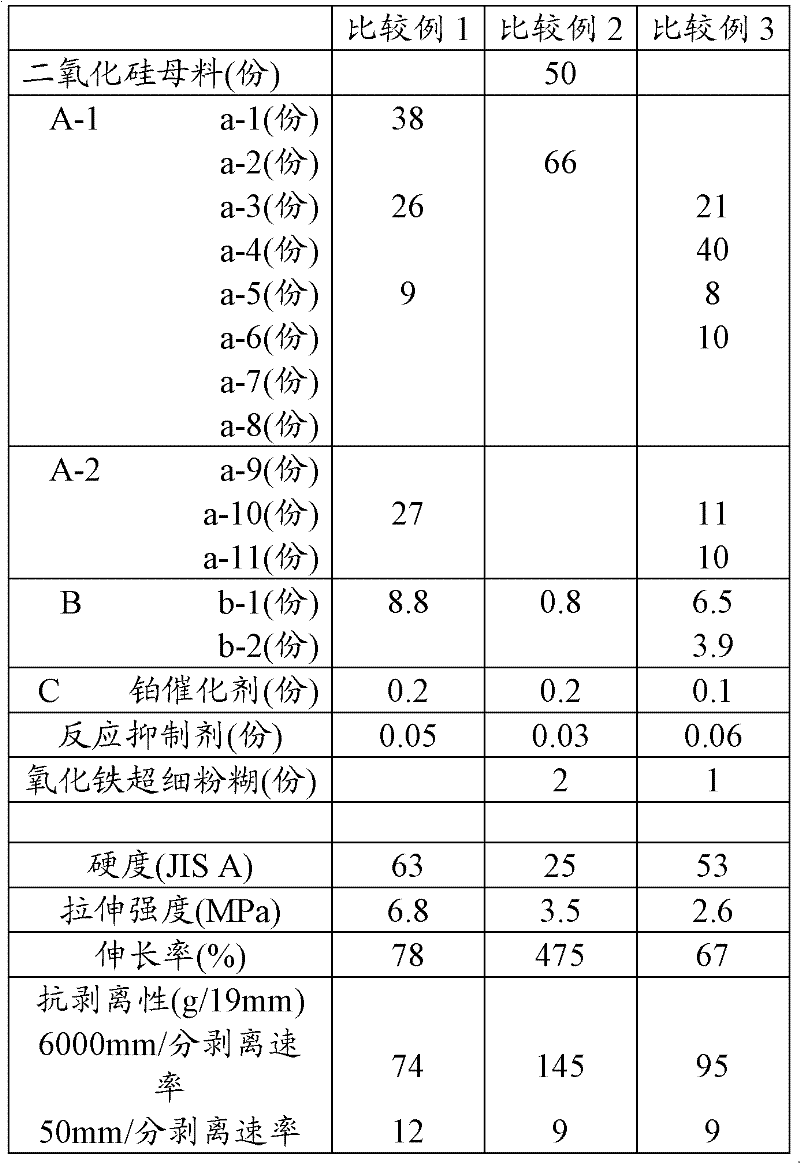

Embodiment 1-5

[0055] The materials shown in Table 1 were mixed until uniform in the amount ratios shown in Table 1 to manufacture a curable silicone rubber composition. The resulting composition was press cured at 120°C for 10 minutes and then kept in an oven at 200°C for an additional 4 hours to produce a 2 mm thick cured sheet. The resulting cured sheet was used to measure hardness, tensile strength, elongation and peel resistance according to the following methods. The results are listed in Table 1.

[0056] Test, measurement and evaluation methods

[0057] The properties of the cured silicone material (hardness, tensile strength, elongation and peel resistance) were measured using the following methods.

[0058] (1) Hardness

[0059] The hardness was measured using a Type A durometer specified in JIS K 6253.

[0060] (2) Tensile strength and elongation

[0061] Tensile strength and elongation were measured according to the method specified in JIS K 6251.

[0062] (3) Peel r...

Embodiment 6

[0097] The following were introduced into a planetary mixer and mixed for 2 hours: 30 parts of quartz powder (Tatsumori Co., Ltd.) having an average particle diameter of 5 μm, 3 parts of 2 Surface hydrophobized pyrogenic silica (Nippon Aerosil) of the BET specific surface area of / g, and 100 parts of both ends of the molecular chain are terminated by trimethylsiloxy groups and have a viscosity of 40000mPa·s and A dimethylsiloxane-methylvinylsiloxane copolymer having a vinyl group content of 0.12% by mass. Added thereto was 1.2 parts of dimethylsiloxanemethylhydrogensiloxane terminated by dimethylhydrogensiloxy groups at both ends of the molecular chain and having a silicon-bonded hydrogen content of about 0.4% by mass. alkane copolymer, 0.05 parts of 1-ethynyl-1-cyclohexanol, and 0.25 parts of isopropanol chloroplatinic acid solution having a platinum concentration of 0.7%, and stirred for 30 minutes. The resulting composition was poured into a 6 mm thick mold and press-cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com