Multi-frequency ultrasonic parallel radiation gas-liquid mass-transfer reaction device

A gas-liquid mass transfer and reaction device technology, applied in the field of ultrasonic chemistry, can solve the problems of low energy utilization efficiency, single ultrasonic frequency, no gas-liquid two-phase flow, etc., and achieves diversified experimental operating conditions and high sound field density value. , layout scientific and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be further explained below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

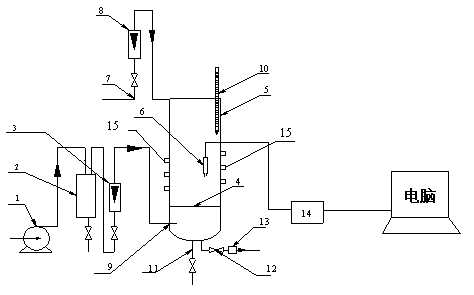

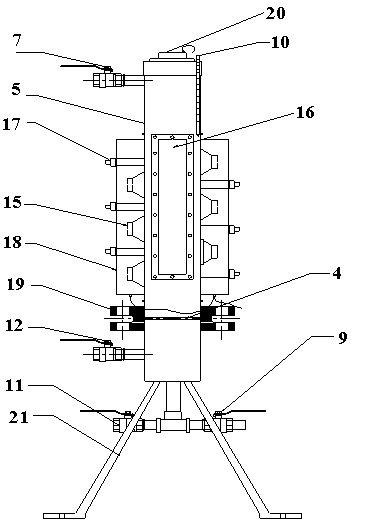

[0027] Such as figure 1 As shown, a multi-frequency ultrasonic parallel radiation gas-liquid mass transfer reaction device includes a compressor 1, a gas buffer tank 2, a gas flow meter 3, a distribution plate 4, an ultrasonic bubbling reaction tower 5, a double conductivity probe 6, a liquid Phase inlet 7, liquid flow meter 8, air inlet 9, temperature measuring device 10, sewage outlet 11, water outlet 12, liquid seal 13, bubble characteristic parameter measuring instrument 14, ultrasonic transducer 15 and connecting pipeline; Machine 1, gas buffer tank 2, gas flow meter 3, ultrasonic bubbling reaction tower 5, double conductance probe 6 and bubble characteristic parameter measuring instrument 14 are connected successively; 8. The liquid phase inlets 7 are connected successively....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com