Beneficiation reagent and method for separating copper-molybdenum mixed concentrates

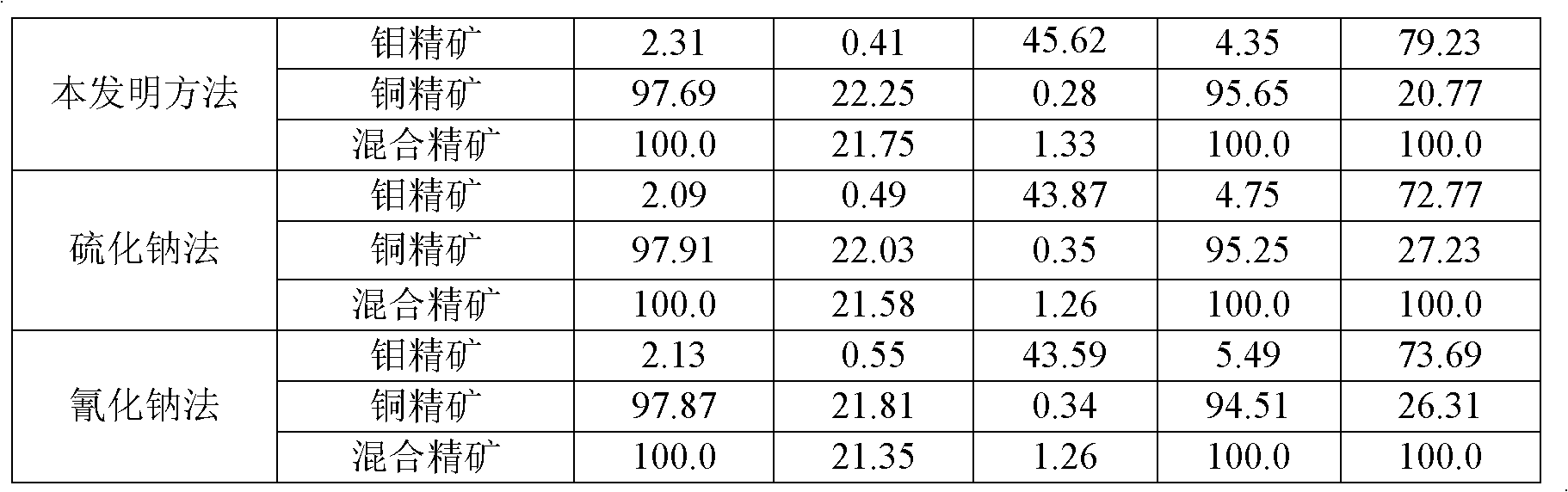

A copper-molybdenum mixed concentrate and beneficiation reagent technology, applied in solid separation, flotation, etc., can solve the problems of fast consumption of Knox reagent, lack of industrial application prospects, loss of inhibition efficiency, etc., and achieve high molybdenum recovery rate, The effect of strong adaptability and less dosage of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

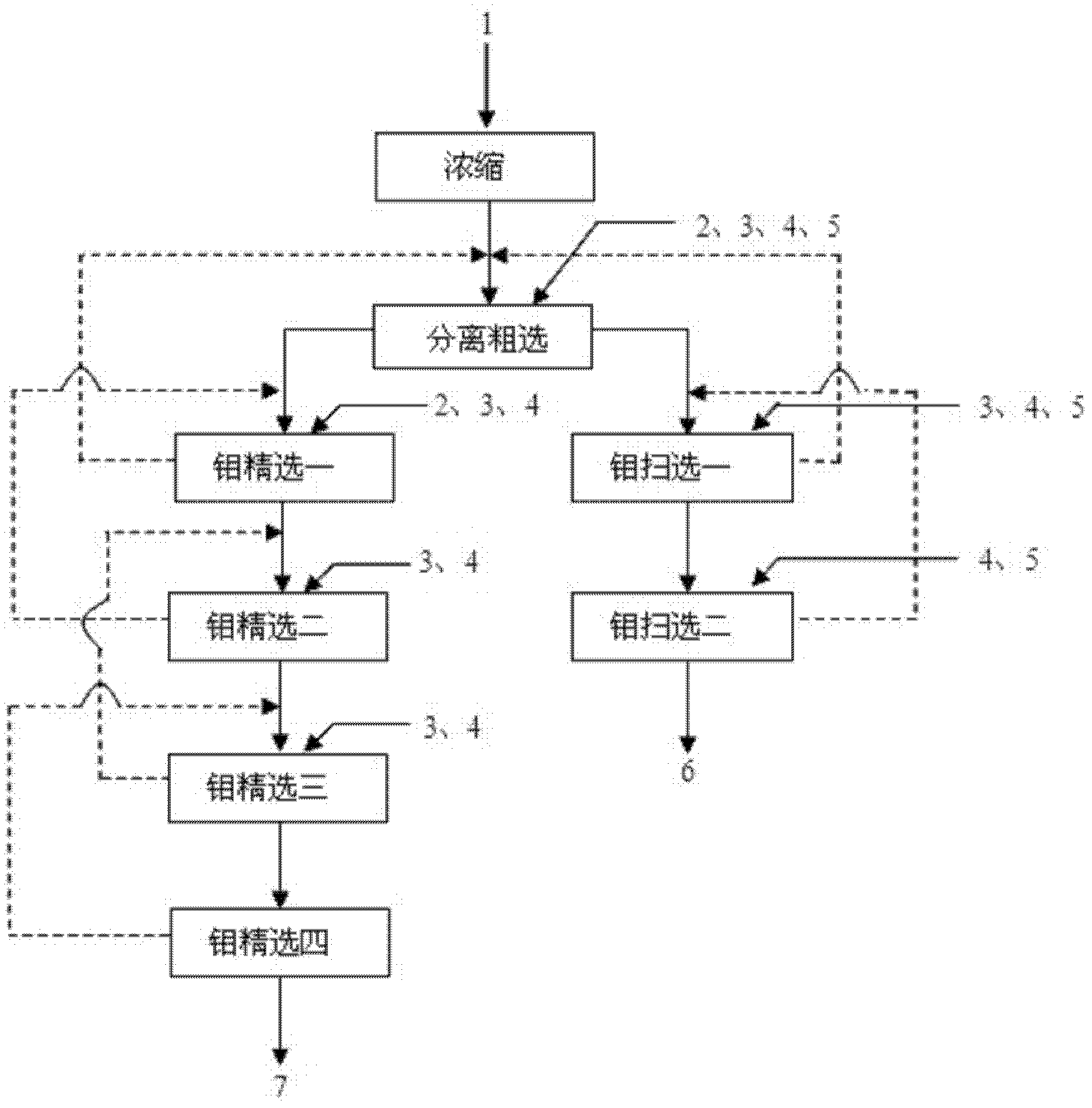

[0024] Specific embodiments of the present invention are embodied by the following drawings and their descriptions. A beneficiation agent and method for separating copper-molybdenum mixed concentrate. The beneficiation agent used for separation of copper-molybdenum mixed concentrate is any one of oxalic acid, water glass, sulfonated kerosene, ethylthiourethane or a combination thereof.

[0025] Molecular formula of oxalic acid: C6H8O7

[0026] Molecular formula of water glass: Na2SiO3.9H2O

[0027] Sulfonated kerosene: Sulfonated kerosene, also known as No. 260 solvent oil, is sulfonated kerosene. It is characterized by uniform and slow evaporation speed, less aromatic hydrocarbon content, low toxicity and high safety. No odor, pure quality, no residue after evaporation, not easy to oxidize when heated.

[0028] Molecular formula of ethylthiocarbamate (common name Z-200): (CH3)2CHOC(S)NHC2H5

[0029] According to per ton of copper-molybdenum mixed concentrate feed, the amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com