High-frequency electric heating welding device

A high-frequency electric heating and welding device technology, used in high-frequency current welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of large pollution, environmental protection, low efficiency and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order for those skilled in the art to better understand the technical solutions provided by the present invention, the following will be described in conjunction with specific embodiments.

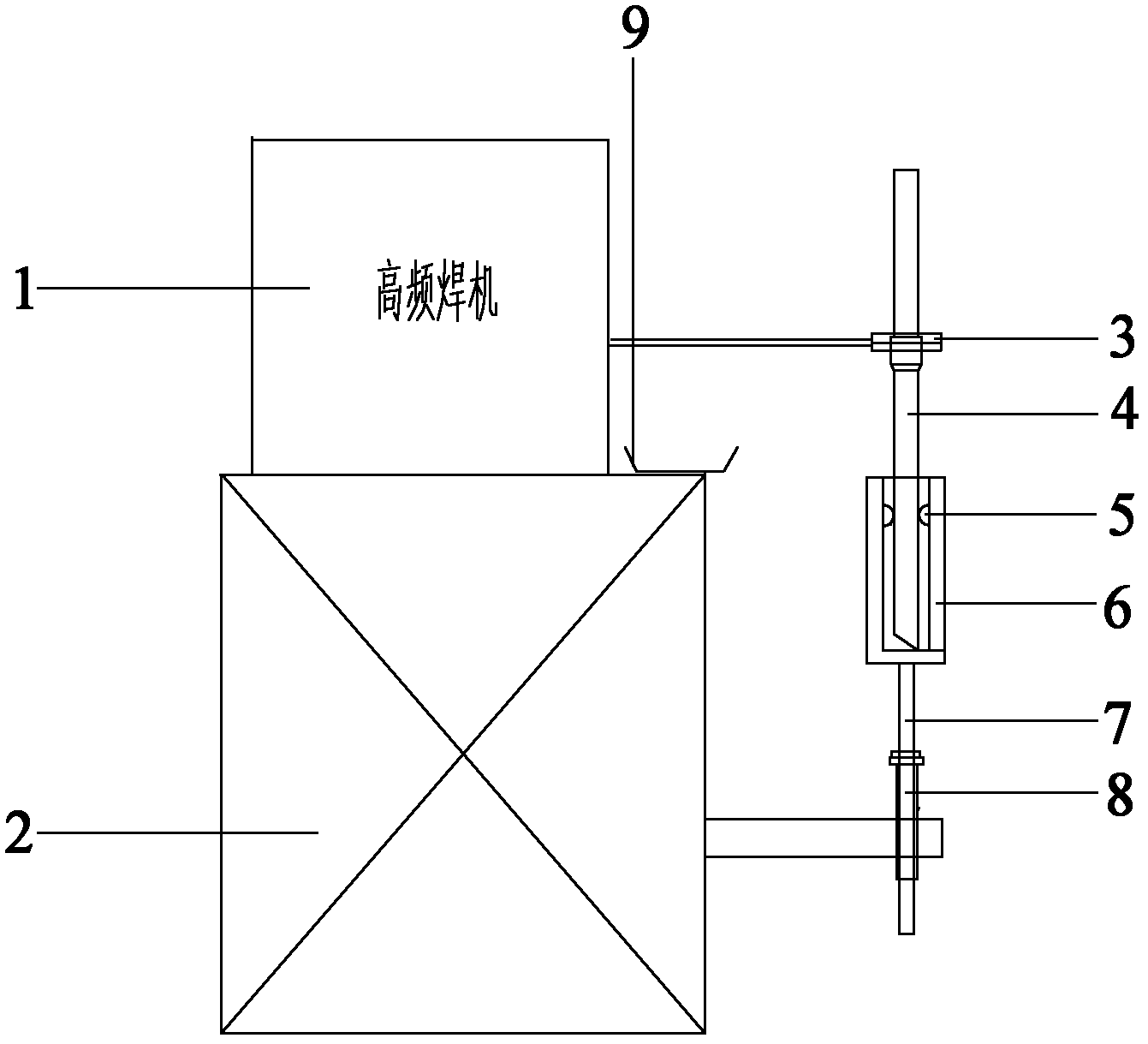

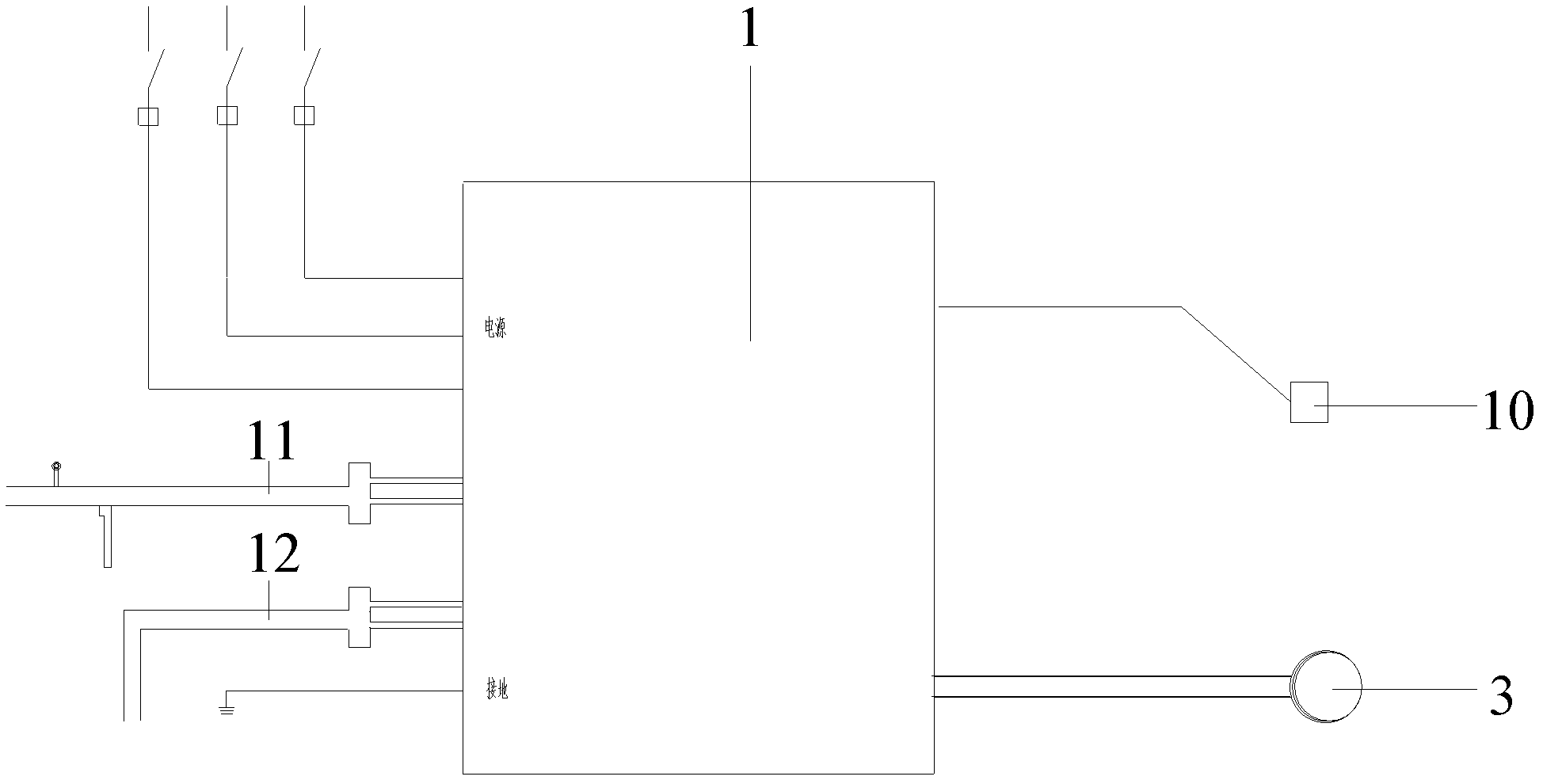

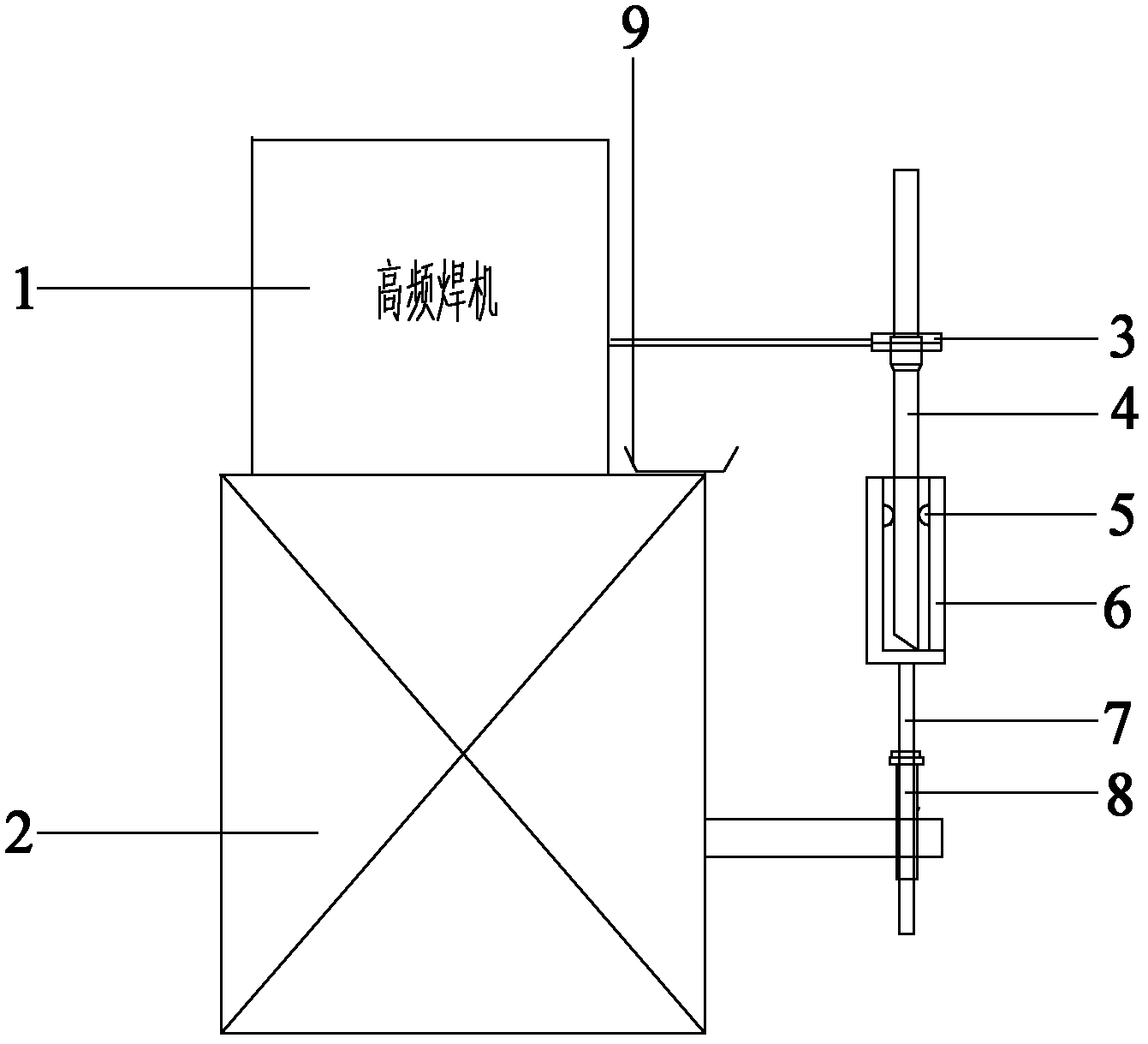

[0016] See figure 1 and figure 2 , figure 1 It is a structural representation of the high-frequency electric heating welding device of the present invention Figure 1 ; figure 2 It is a structural representation of the high-frequency electric heating welding device of the present invention Figure II .

[0017] The high-frequency electrothermal welding device provided by the present invention includes a high-frequency electrothermal welding machine 1 and a welded pipe support 2. The high-frequency electrothermal welding machine 1 is provided with an induction coil 3, and the welded pipe support 2 is provided with a lifting mechanism. The lifting mechanism is provided with a fixed mold The welded pipe 4 is fixed in the fixed mold, and the welded part of the welded pipe 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com