Top gas pressure recovery turbine generating system

A blast furnace gas and power generation system technology, which is applied in the field of blast furnace gas residual pressure turbine power generation system, can solve the problems of wasting blast furnace gas residual pressure energy, increase unit maintenance workload, economic losses, etc., so as to reduce system maintenance amount and improve use. efficiency, and the effect of increasing power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

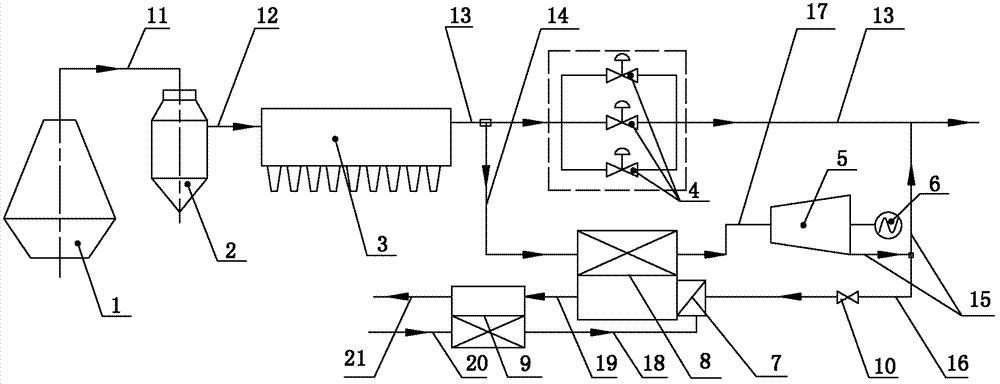

[0011] like figure 1 As shown, the blast furnace gas residual pressure turbine power generation system includes a gravity dust collector 2, a bag filter 3, a pressure reducing valve group 4, a turbine 5, a generator 6, a first pipeline 11, a second pipeline 12, a first pipeline Three pipelines 13, the fourth pipeline 14, the fifth pipeline 15; the input port of the gravity dust collector 2 is connected with the gas output port of the blast furnace 1 (ironmaking blast furnace) by the first pipeline 11, and the output port of the gravity dust collector 2 is connected by the first pipeline 11 The second pipeline 12 is connected with the input port of the bag filter 3, and the output port of the bag filter 3 is connected with the third pipeline 13. The third pipeline 13 is provided with a pressure reducing valve group 4, and the pressure reducing valve group 4 is connected with the bag filter The third pipeline 13 between the output ports of 3 communicates with the input end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com