Drive power supply of laser diodes

A technology of laser diode and driving power supply, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of insufficient current control accuracy, poor anti-interference, large current ripple coefficient, etc., and achieve the output of laser diode pumped laser. The single pulse energy or power is stable and the beam quality is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

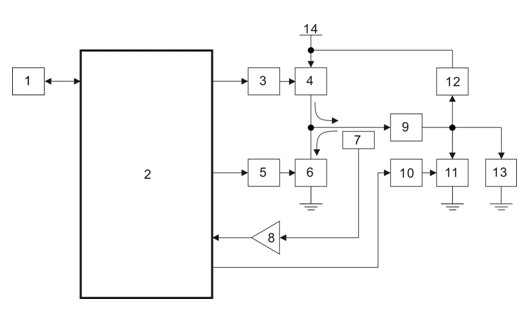

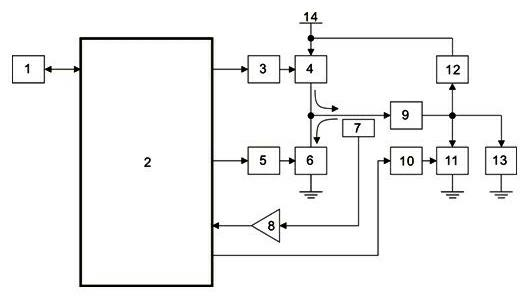

[0022] see first figure 1 , figure 1 It is a structural principle diagram of the laser diode driving power supply of the present invention. As can be seen from the figure, the laser diode drive power supply of the present invention comprises an embedded controller 2, the first pulse width modulation port 0 of the embedded controller 2 is connected to the input pin of the first field effect transistor drive chip 3, the first pulse width modulation port 0 of the embedded controller 2 The output pin of the FET drive chip 3 is connected to the G pin of the P-channel FET 4, and the S pin of the P-channel FET 4 is connected to the positive pole of the power supply VDD14;

[0023] The second pulse width modulation port of the embedded controller 2 is connected to the input pin o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com