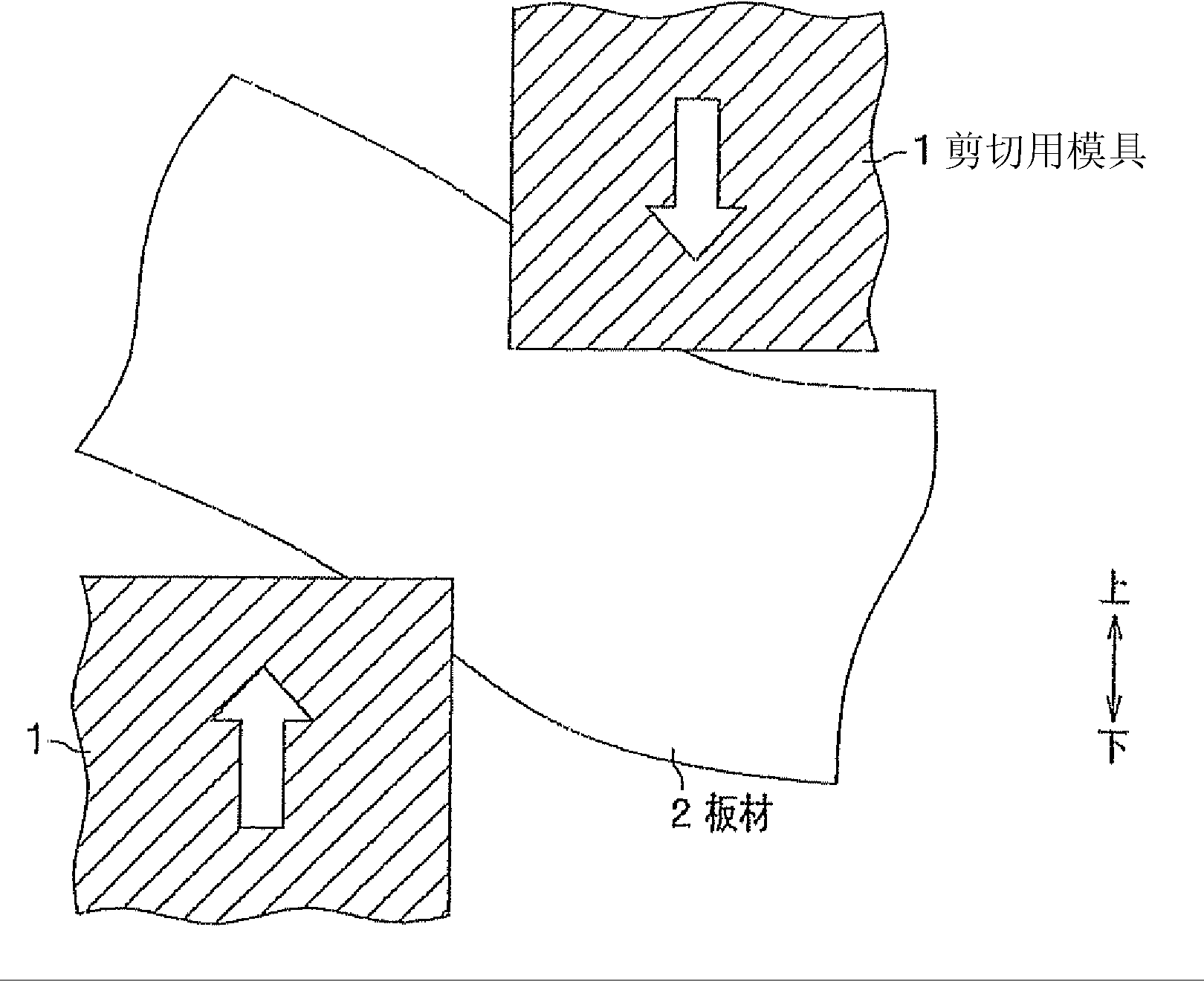

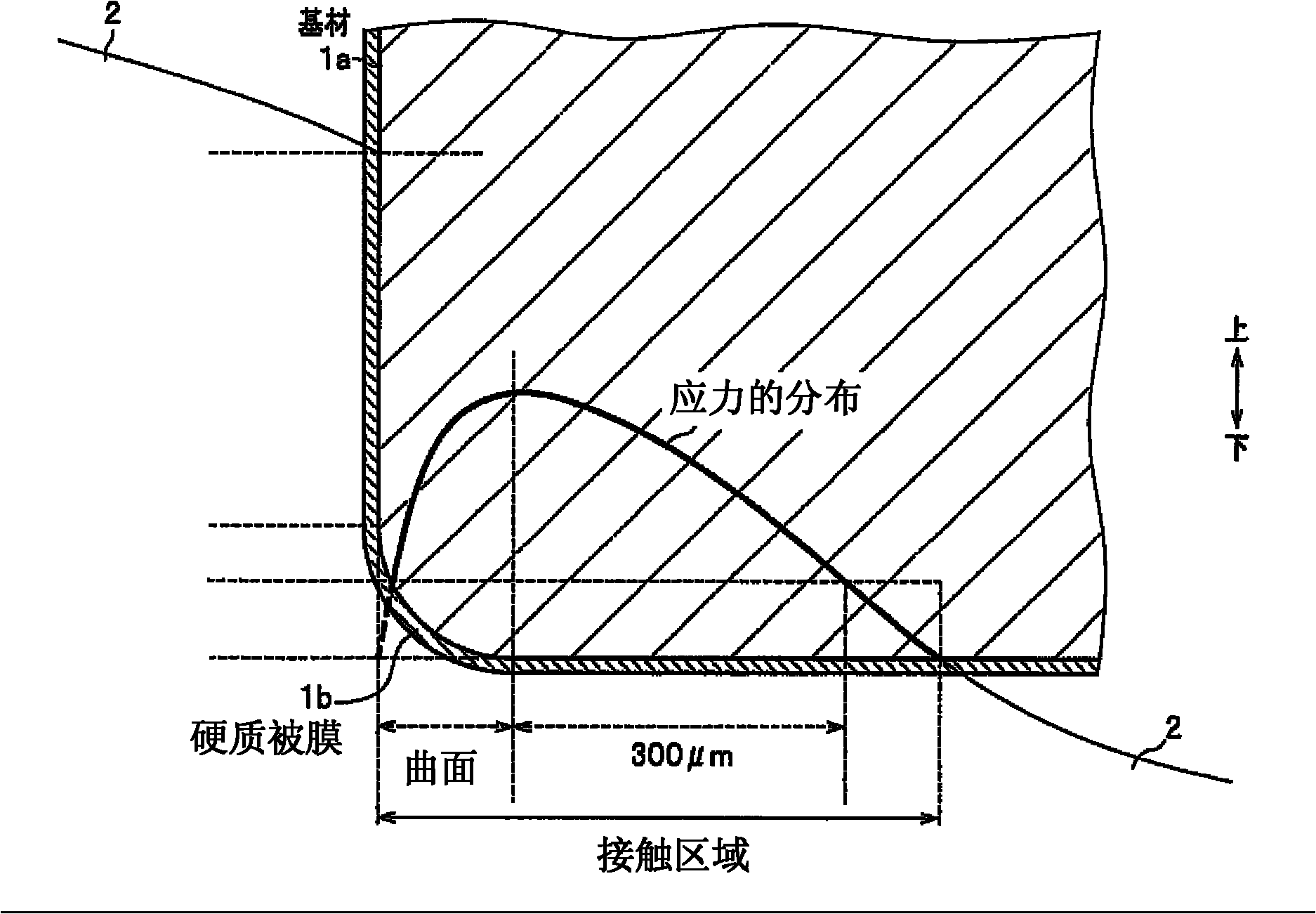

Shearing die and method for manufacturing the same

A manufacturing method and mold technology, applied in the field of shearing molds and their manufacturing, can solve the problems of long-life residual, accelerated mold rupture, etc., and achieve the effect of excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0112] Next, examples (test materials Nos. 2, 4, 6, 8-10, 13-21, 23, 24, 26- 46) Compared with the comparative examples (test material No. 1, 3, 5, 7, 11, 12, 22, 25) which do not satisfy the requirements of the present invention, it will be specifically described.

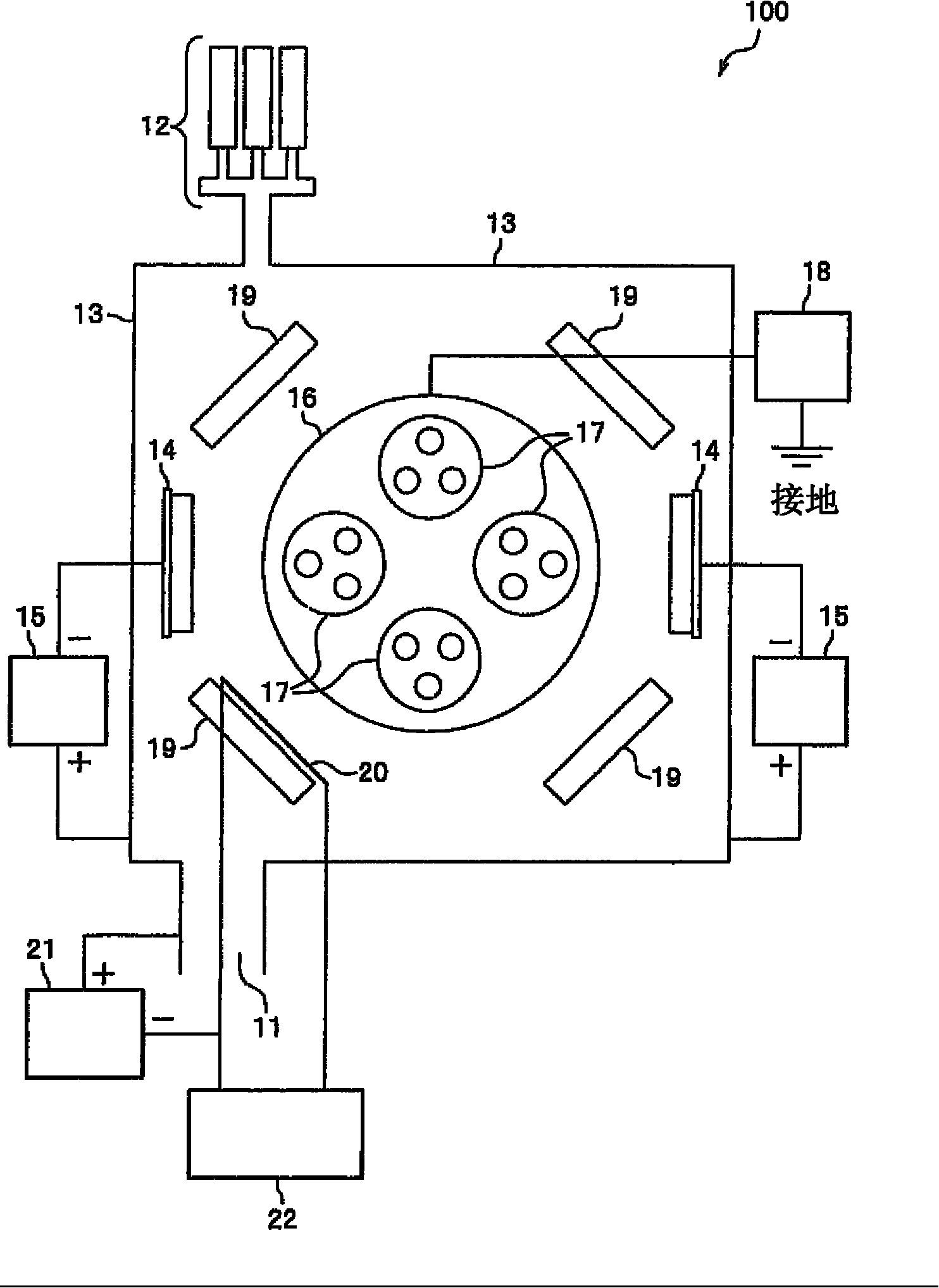

[0113]

[0114] use image 3 The film forming device shown (in the table is normal arc), equipped with Figure 4 The film-forming device of the linear arc-type evaporation source shown (in the table is Filtration 1), equipped with Figure 5 The film-forming device of the 90° curved arc evaporation source shown (in the table is Filtration 2), or the hollow cathode type film-forming device (in the table is HCD), including die steel (JIS-SKD11, HRC60) The hard coatings shown in Tables 1 to 3 were formed on the substrates.

[0115] As a film forming method, first, the base material is set in a film forming apparatus to achieve 1×10 -3 After the chamber was exhausted so that the Pa was lower, the substrate was he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com