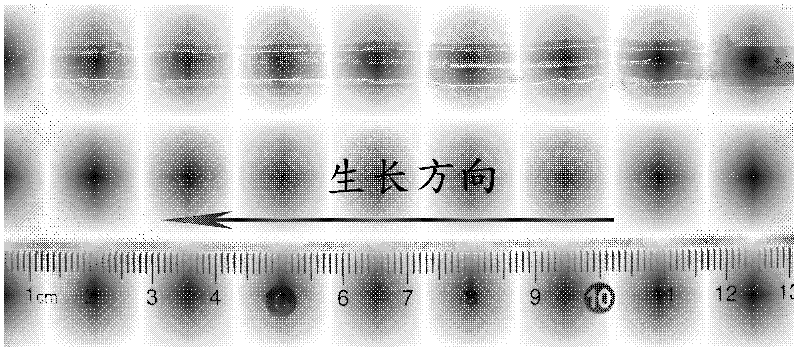

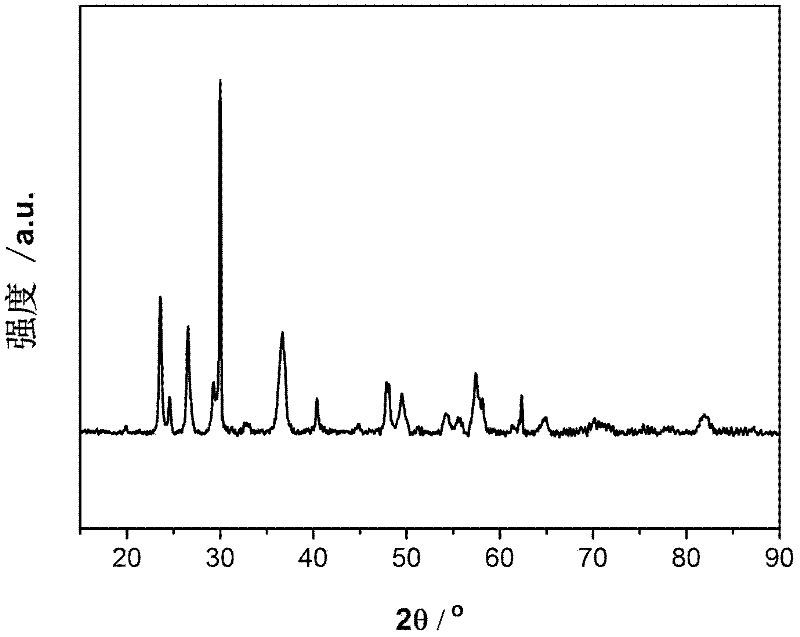

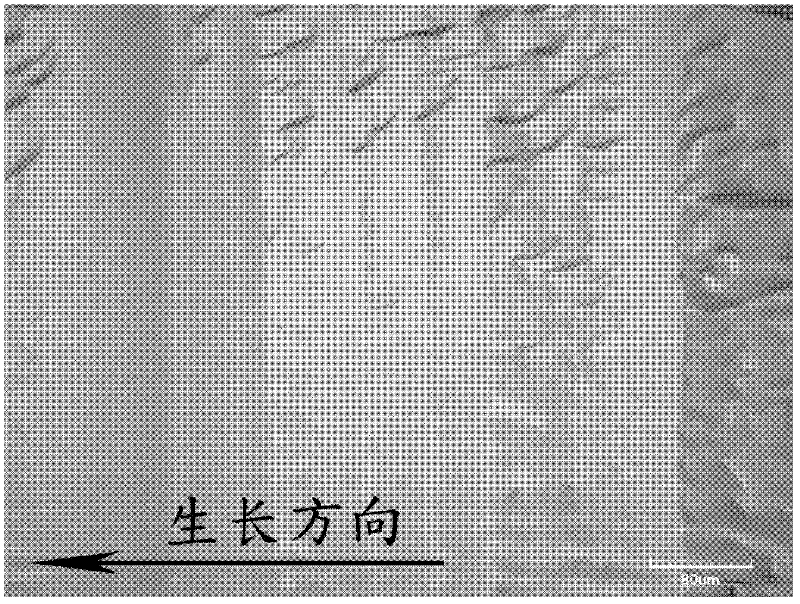

Method for growing large size Ta2O5 single crystal by using floating zone method

A large-scale, floating-zone technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., to achieve the effects of eliminating potential pollution, high production efficiency, and short growth cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Powder preparation: mix Ta 2 o 5 The powder was ball milled for 12 hours and dried at 80°C for 8 hours.

[0036] (2) Rod preparation: Ta after ball milling 2 o 5 Put the powder into a rubber tube and seal it, then use a vacuum pump to evacuate for 10 minutes, and then put it into a bar-shaped green bar under isostatic pressure at a pressure of 70Mpa;

[0037] (3) Seed crystal preparation: put the obtained green billet into a high-temperature sintering furnace, and obtain a polycrystalline rod after the sintering temperature is 1450° C. and the sintering time is 12 hours;

[0038] (4) Material rod and seed crystal installation: fix the pressed biscuit rod on the material rod of the single crystal furnace as the material rod, put the polycrystalline rod into the floating zone furnace as the seed crystal, seed crystal and material rod in a straight line in the vertical direction. Adjust the position of the rod and seed so that it touches and is at the same level a...

Embodiment 2

[0042] (1) Powder preparation: mix Ta 2 o 5 The powder was ball milled for 12 hours and dried at 80°C for 8 hours.

[0043] (2) Rod preparation: Ta after ball milling 2 o 5 Put the powder into a rubber tube and seal it, then use a vacuum pump to evacuate for 5 minutes, and then put it into a bar-shaped green bar under isostatic pressure at a pressure of 60Mpa;

[0044] (3) Seed crystal preparation: put the prepared green billet into a high-temperature sintering furnace, and obtain a polycrystalline rod after the sintering temperature is 1550° C. and the sintering time is 24 hours;

[0045] (4) Material rod and seed crystal installation: fix the sintered polycrystalline rod on the material rod of the single crystal furnace as the material rod, put the polycrystalline rod into the floating zone furnace as the seed crystal, the seed crystal and the material rod are vertically in a straight line. Adjust the position of the rod and seed so that it touches and is at the same le...

Embodiment 3

[0049] (1) Powder preparation: mix Ta 2 o 5 The powder was ball milled for 12 hours and dried at 80°C for 6 hours.

[0050] (2) Rod preparation: Ta after ball milling 2 o 5 Put the powder into a rubber tube and seal it, then evacuate it with a vacuum pump for 8 minutes, and then put it into a bar-shaped green bar under isostatic pressure at a pressure of 65Mpa;

[0051] (3) Seed crystal preparation: put the obtained green billet into a high-temperature sintering furnace, and obtain a polycrystalline rod after the sintering temperature is 1600° C. and the sintering time is 12 hours;

[0052] (4) Material rod and seed crystal installation: After sintering, the polycrystalline rod is fixed on the material rod of the single crystal furnace as a material rod, and the grown Ta 2 o 5 The single crystal is put into the floating zone furnace as the seed crystal, and the seed crystal and the material rod form a straight line in the vertical direction. Adjust the position of the ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com