Method for in-situ full-field early detection of stainless steel pitting

An early detection, stainless steel technology, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as low resolution, inability to detect early pitting corrosion of stainless steel, inability to observe and detect local corrosion information of electrodes, etc., to achieve Intuitive Resolution Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

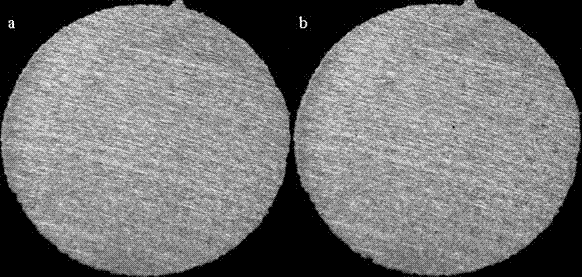

[0022] Step 1: Sample preparation, first process 304 stainless steel into a disc with a diameter of 5 mm and a thickness of 4 mm. The metallographic sample mounting machine is used to encapsulate the stainless steel wafer (the mounting material is phenolic resin powder), and it is polished to 400# by water-grinding paper from coarse to fine, and the working surface of the sample is cleaned and degreased with acetone. After drying, it is short Store in a dry dish for later use.

[0023] Step 2: Prepare the experimental soaking solution. The experimental soaking solution is divided into indicator and bulk solution, wherein the indicator is mixed with component 1 and component 2 solutions, and component 1 is 10% potassium ferricyanide solution prepared with pure water , component 2 is obtained by dissolving phenolphthalein in alcohol, the concentration is 0.1 g / ml, the volume ratio of 50:1 component 1 and component 2 solution is mixed, and the indicator used in the experiment is ...

Embodiment 2

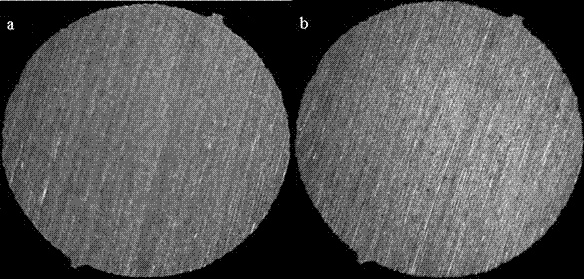

[0027] Except that water abrasive paper is polished to 800# from coarse to fine, other is the same as embodiment 1, and experimental result is as follows figure 2 As shown, the pitting corrosion time is 402 s.

Embodiment 3

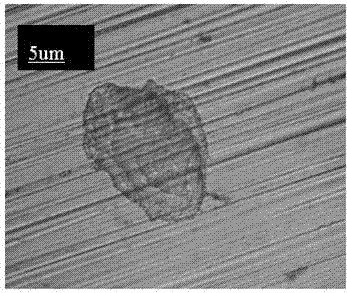

[0029] Except that the water abrasive paper is polished to 1200# from coarse to fine, other is the same as embodiment 1, and the experimental results are as follows image 3 As shown, the pitting time is 463 s. Metallographic observation of the corrosion pits revealed that the diameter of the corrosion pits was about 10 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com