Wide spectrum metal dielectric film grating and optimization method thereof

A technology of metal dielectric and dielectric film, applied in the field of diffraction grating, can solve the problem that it is difficult to obtain diffraction efficiency and anti-laser damage threshold, the bandwidth cannot meet the requirements of femtosecond laser wide spectrum, and cannot meet the requirements of femtosecond laser high diffraction efficiency and other problems, to achieve the effect of high resistance to laser damage threshold, excellent working bandwidth, and reduced difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

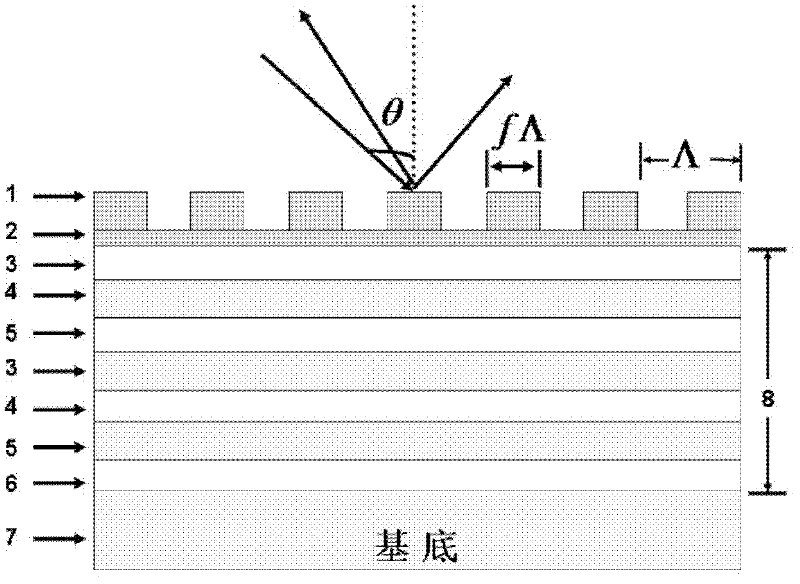

[0031] figure 1 Schematic diagram of the structure principle of the wide-spectrum metal dielectric film grating provided by the present invention, the grating is sequentially composed of a substrate 7, a metal Ag film 6, a SiO 2 Dielectric film 5, HfO 2 Dielectric film 4, TiO 2 Dielectric film 3, remaining film layer 2 and surface grating structure 1; SiO 2 Dielectric film, HfO 2 Dielectric film and TiO 2 The dielectric film forms a multilayer dielectric film in turn, and the metal Ag film and the multilayer dielectric film form a high reflection film 8; the high reflection film 8 formed by the metal Ag film and the multilayer dielectric film can provide high The reflectivity to ensure that the incident light can be fully reflected and diffracted. Above the high reflection film 8 is the remaining film layer 2 after the surface grati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle of incidence | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Center wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com