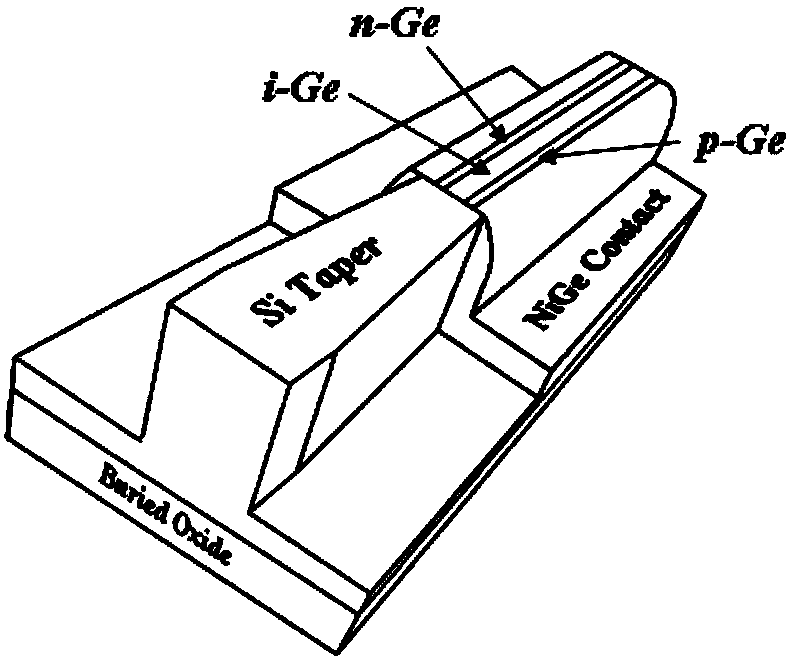

Method for preparing Ge photoelectric detector with transverse p-i-n structure

A p-i-n, photodetector technology, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problem of reducing the light signal responsivity of the device, and achieve the effect of alleviating the requirements of photolithography, small series resistance and improving device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

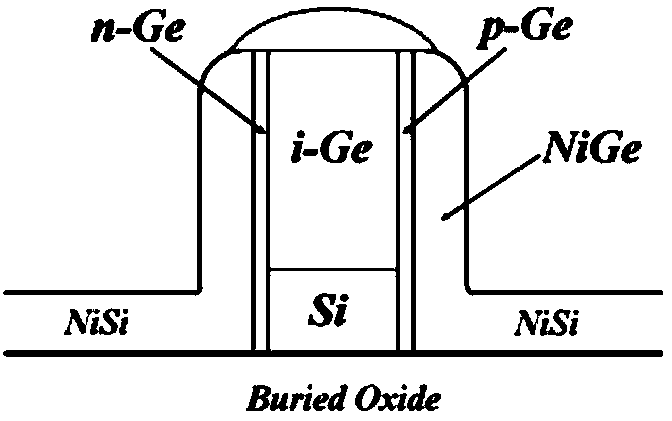

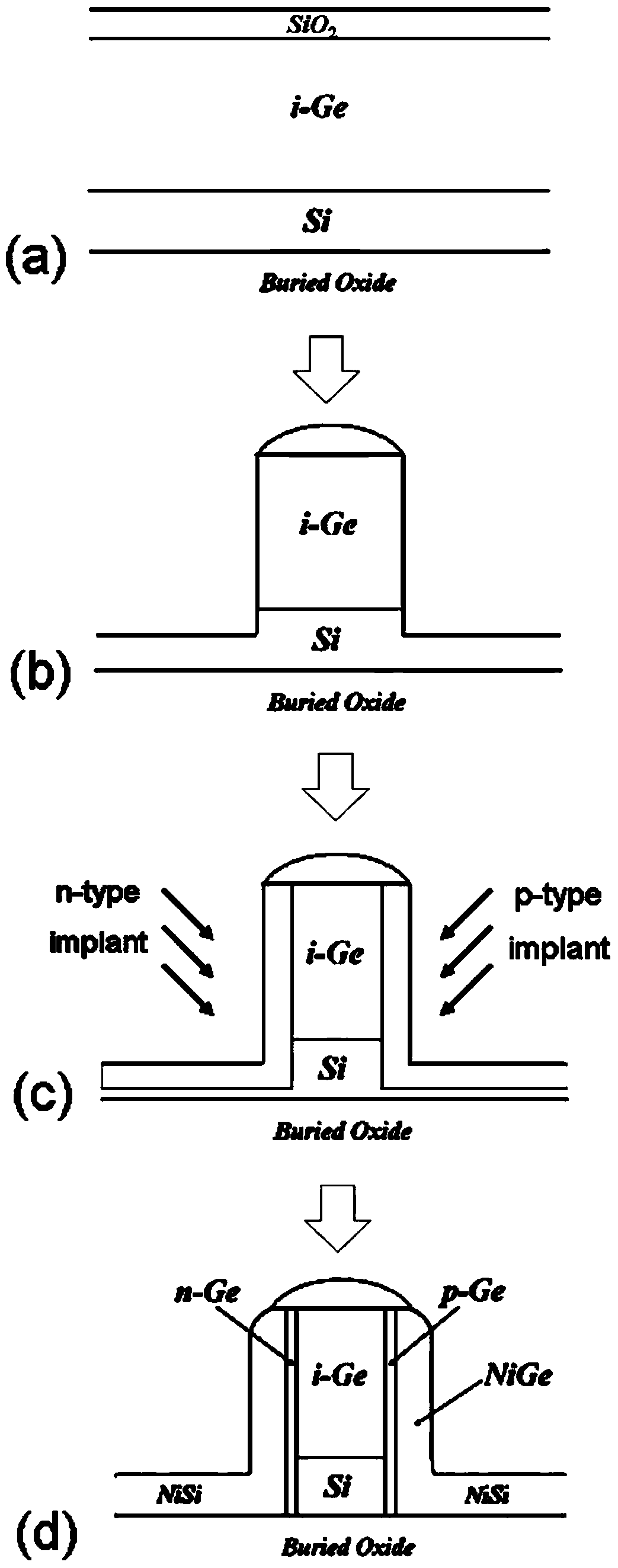

[0023] The invention combines ion direction finding injection and NiGe self-alignment technology, and realizes the preparation of the sub-micron-level line size lateral p-i-n structure Ge photodetector by means of conventional photolithography conditions.

[0024] In step 1), the substrate for Ge epitaxial growth is a silicon-on-insulating SOI substrate. The growth can be obtained by a two-step growth method under ultra-high vacuum conditions, that is, a low-temperature Ge buffer layer of tens of nanometers is formed at a low temperature on a clean Si substrate (low temperature is about 350℃), and then a high temperature is grown on the buffer layer. The Ge layer (high temperature temperature is about 650°C), germane is used as the gas source, and the total thickness of the Ge layer is about 1 μm. The epitaxial germanium layer is then covered with SiO by chemical vapor deposition 2 The thickness of the layer is above 200nm.

[0025] In step 2), use microelectronic lithography tech...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com