Circuit board and manufacturing method thereof

A circuit board production and circuit board technology, which is applied in the direction of printed circuit components, electrical connection printed components, and printed component electrical connection formation, can solve the problem of double-sided circuit boards that are difficult to meet the requirements of light weight and miniaturization of portable electronic devices. Problems such as large thickness and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

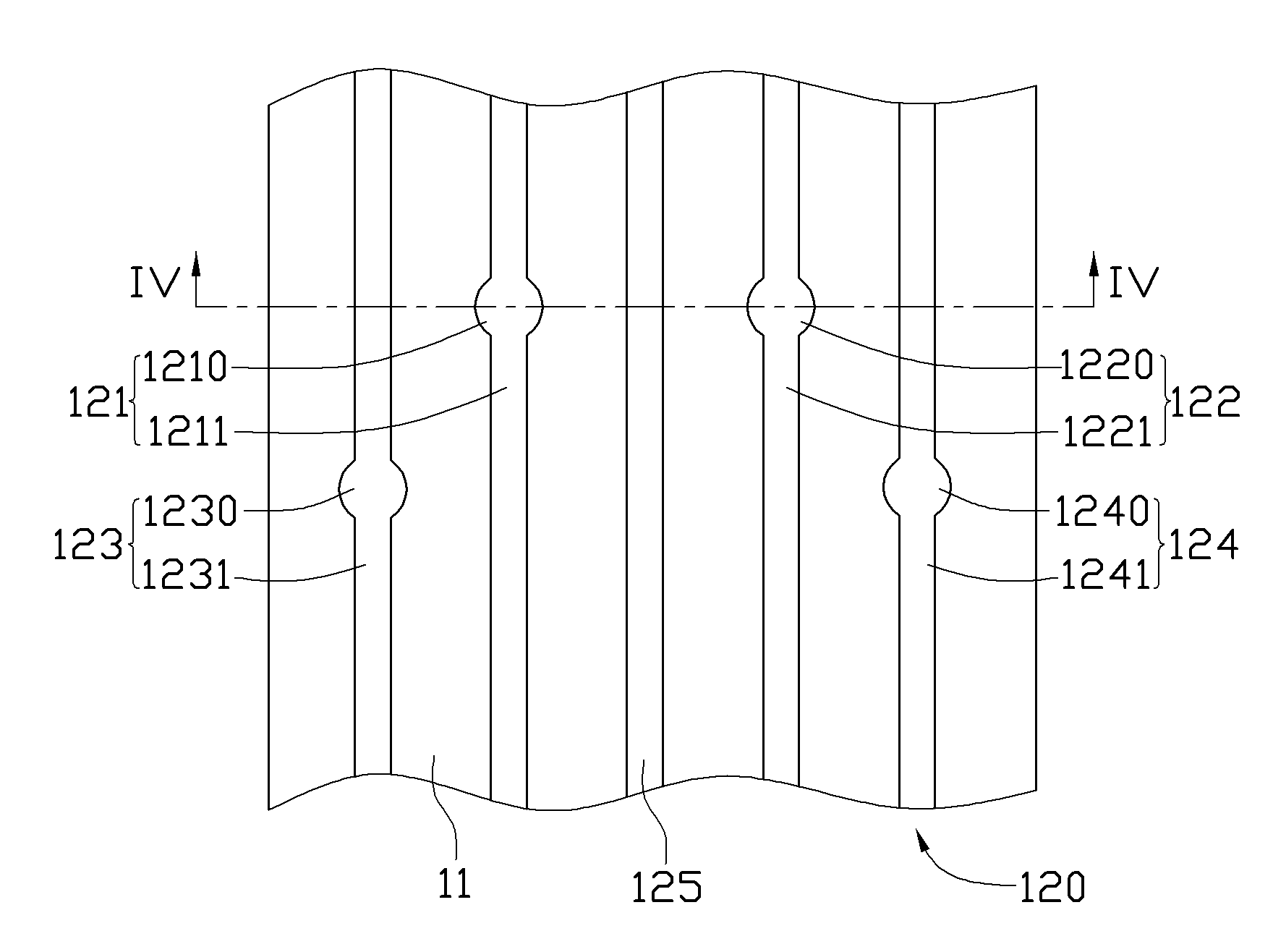

[0049] The circuit board provided by the technical solution and its manufacturing method will be further described in detail below in conjunction with the accompanying drawings and embodiments.

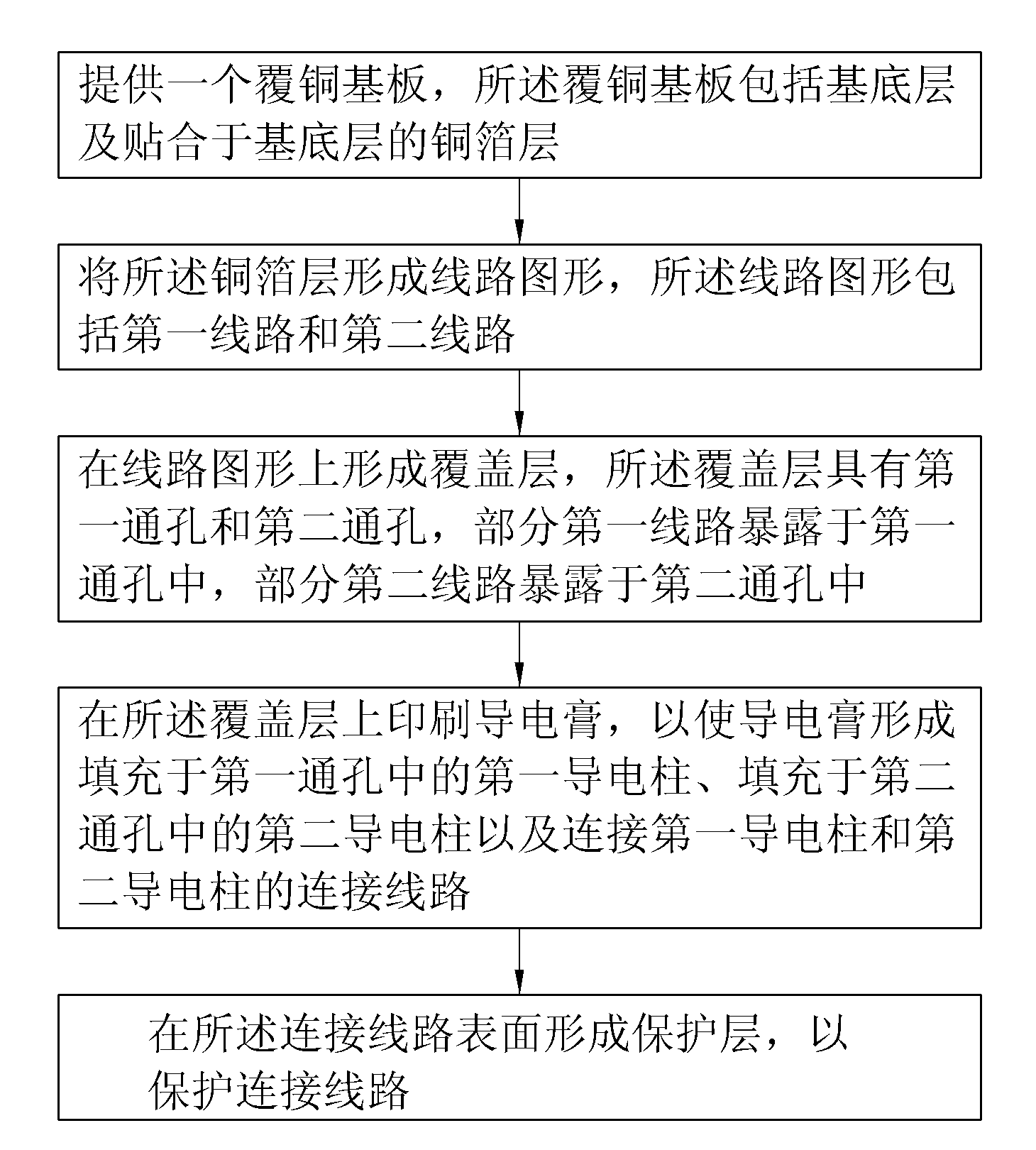

[0050] see figure 1 The circuit board manufacturing method provided by the embodiment of the technical solution includes the steps:

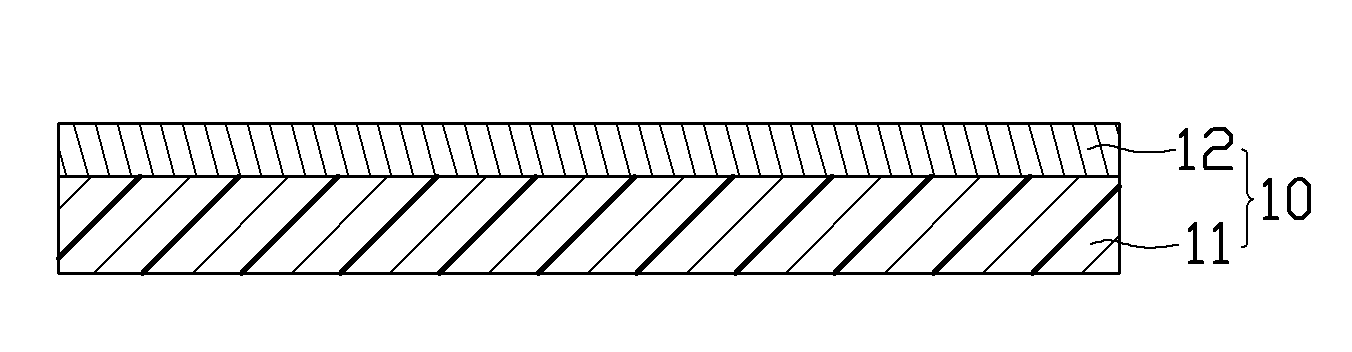

[0051] For a first step, see figure 2 , providing a copper-clad substrate 10 , the copper-clad substrate 10 includes a base layer 11 and a copper foil layer 12 attached to the base layer 11 .

[0052]In this embodiment, the copper clad substrate 10 is a single-layer copper foil substrate, that is, it only includes one copper foil layer 12 . The material of the base layer 11 can be a hard material, such as epoxy resin, glass fiber cloth, etc., or a flexible material, such as polyimide (Polyimide, PI), polyethylene terephthalate ( Polyethylene Terephthalate (PET), Teflon, Polyamide, Polymethylmethacrylate, Polycarbonate or Polyimide-Polyethylene-Terep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com