Method for casting and rolling aluminum alloy plate

An aluminum alloy plate, casting and rolling technology, applied in metal rolling and other directions, can solve problems such as horseshoe cracks, affecting product quality, sticking rolls, etc., to reduce the time of hot rolling and cold rolling, shorten the production cycle, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

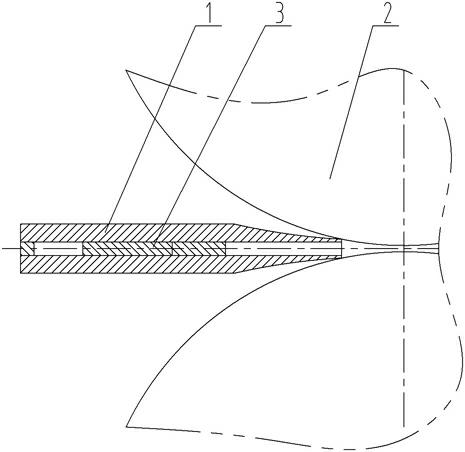

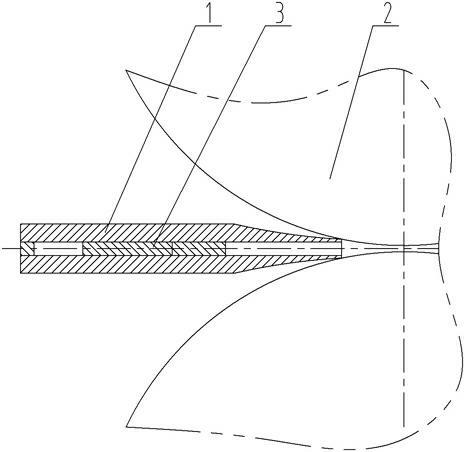

Image

Examples

Embodiment 1

[0030] Embodiment 1: a kind of cast-rolling method of aluminum alloy plate of this example is used for producing 3004 aluminum alloy plate, and its steps are:

[0031] a. Put the leftovers into the melting furnace first, and then put into the aluminum ingot. The composition of the leftovers and the ratio of aluminum is: Si: 0.1%, Fe: 0.4%, Cu: 0.1%, Mn: 1.0%, and the balance is Al, and the melting is almost completed. Add the alloying agent according to the composition ratio. The ratio of the alloying agent composition and aluminum is: Si: 0.15%, Fe: 0.56%, Cu: 0.15%, Mn: 1.15%, Mg: 0.9%, after standing for 30 minutes Add 2.5kg of refining agent for refining, and adjust the pressure of liquid nitrogen at the same time to ensure that the height of the molten aluminum blown by liquid nitrogen does not exceed 15cm. The refining time is controlled at 15 minutes. After refining is completed and slag is removed, smelting is carried out. The smelting time is 4 hours. The temperature...

Embodiment 2

[0034] Embodiment 2: a kind of cast-rolling method of aluminum alloy plate of this example is used for producing 3004 aluminum alloy plate, and its steps are:

[0035] a. Put the leftover material into the melting furnace first, and then put into the aluminum ingot. The ratio of the leftover material to aluminum is: Si: 0.12%, Fe: 0.45%, Cu: 0.12%, Mn: 1.05%, the balance is Al, and the melting is almost completed. Add the alloying agent according to the composition ratio. The ratio of the alloying agent composition and aluminum is: Si: 0.2%, Fe: 0.63%, Cu: 0.2%, Mn: 1.25%, Mg: 1.1%, after standing for 30 minutes Add 3.5kg of refining agent for refining, and adjust the pressure of liquid nitrogen at the same time to ensure that the height of the molten aluminum blown by liquid nitrogen does not exceed 15cm. The refining time is controlled at 18 minutes. After refining is completed and slag is removed, smelting is carried out. The smelting time is 4.5 hours. The temperature is ...

Embodiment 3

[0038] Embodiment 3: a kind of cast-rolling method of aluminum alloy plate of this example is used for producing 3004 aluminum alloy plate, and its steps are:

[0039] a. Put the leftovers into the smelting furnace first, and then put into the aluminum ingot. The ratio of the leftovers to aluminum is: Si: 0.15%, Fe: 0.5%, Cu: 0.15%, Mn: 1.1%, the balance is Al, and the melting is almost completed. Add the alloying agent according to the composition ratio. The ratio of the alloying agent composition and aluminum is: Si: 0.25%, Fe: 0.68%, Cu: 0.23%, Mn: 1.3%, Mg: 1.2%, after standing for 30 minutes Add 4kg of refining agent for refining, and adjust the pressure of liquid nitrogen at the same time to ensure that the height of liquid aluminum blown by liquid nitrogen does not exceed 15cm. The refining time is controlled at 20 minutes. After refining is completed and slag is removed, smelting is carried out. The smelting time is 5 hours, and the smelting temperature 765°C, then go...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com