Measuring method for maximum ion boundary angle in plasma etching simulation

A measurement method and plasma technology, applied in the field of micro-electromechanical system (MEMS) process simulation, can solve the problems of poor shading performance, inaccurate white light interferometric measurement results, and complicated equipment, so as to reduce the operation repeatability. Requirements, the experimental operation process is simple and easy, and the manufacturing cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

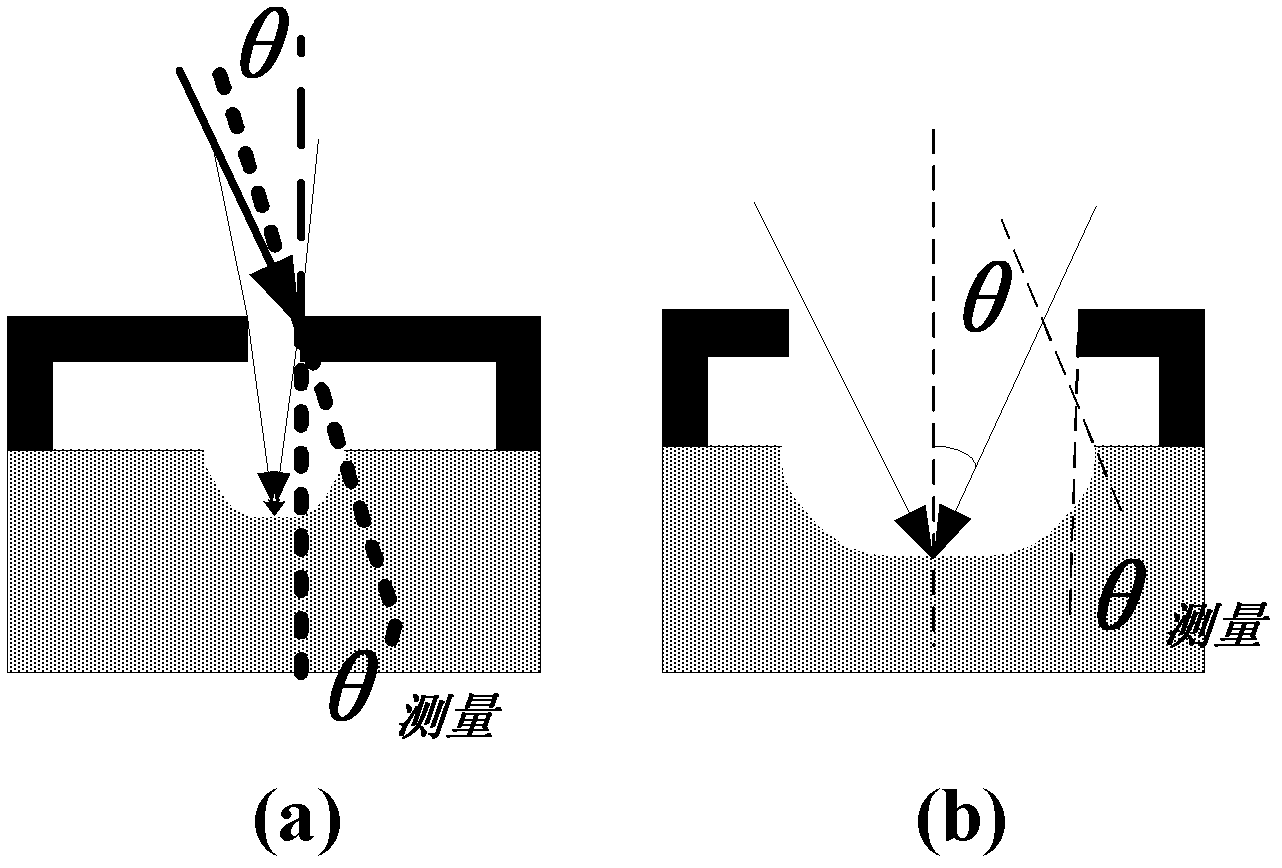

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described through embodiments below in conjunction with the accompanying drawings, but the scope of the present invention is not limited in any way.

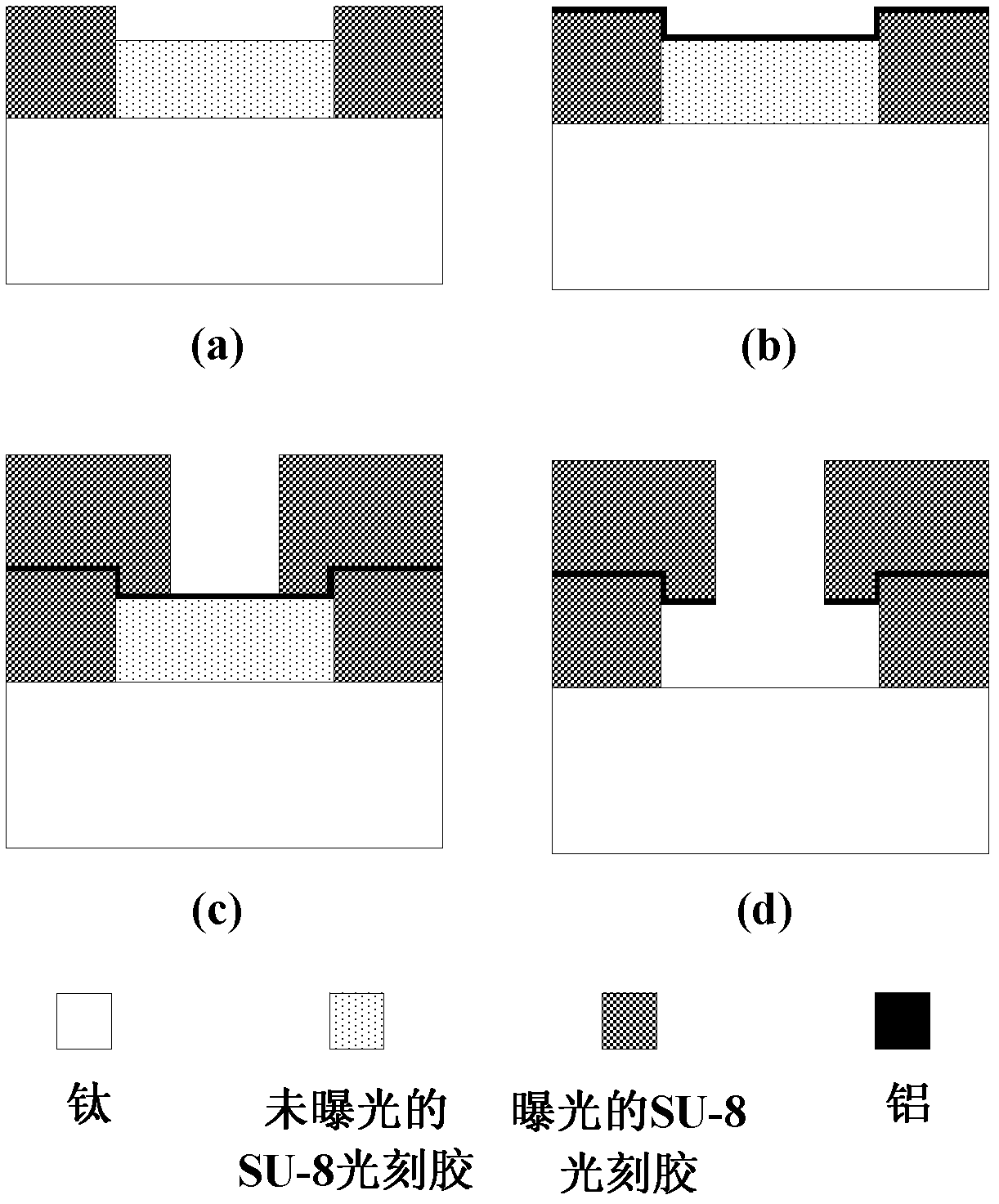

[0057] 1. Realization of suspended structure of SU-8 photoresist

[0058] Su-8 photoresist suspended structure of the present invention is as Figure 5 As shown in (d), this structure facilitates the unimpeded play of the etching effect of non-vertically incident ions, and finally measures the maximum ion boundary angle more accurately through topography measurement, which is used for the very critical "etching parameter "The calibration of the value of R.

[0059] The realization of the suspending structure of the SU-8 photoresist utilizes the following characteristics of the SU-8 photoresist: when the SU-8 photoresist is exposed, it will absorb a certain dose of ultraviolet light to produce crosslinking, which will be retained during development Down; light propagates in the SU-8 ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com