Preparation method of linezolid

A technology of linezolid and oxazolidine, applied in the field of pharmacy, can solve the problems of cumbersome route, high cost, low yield and the like, and achieve the effects of simple route, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

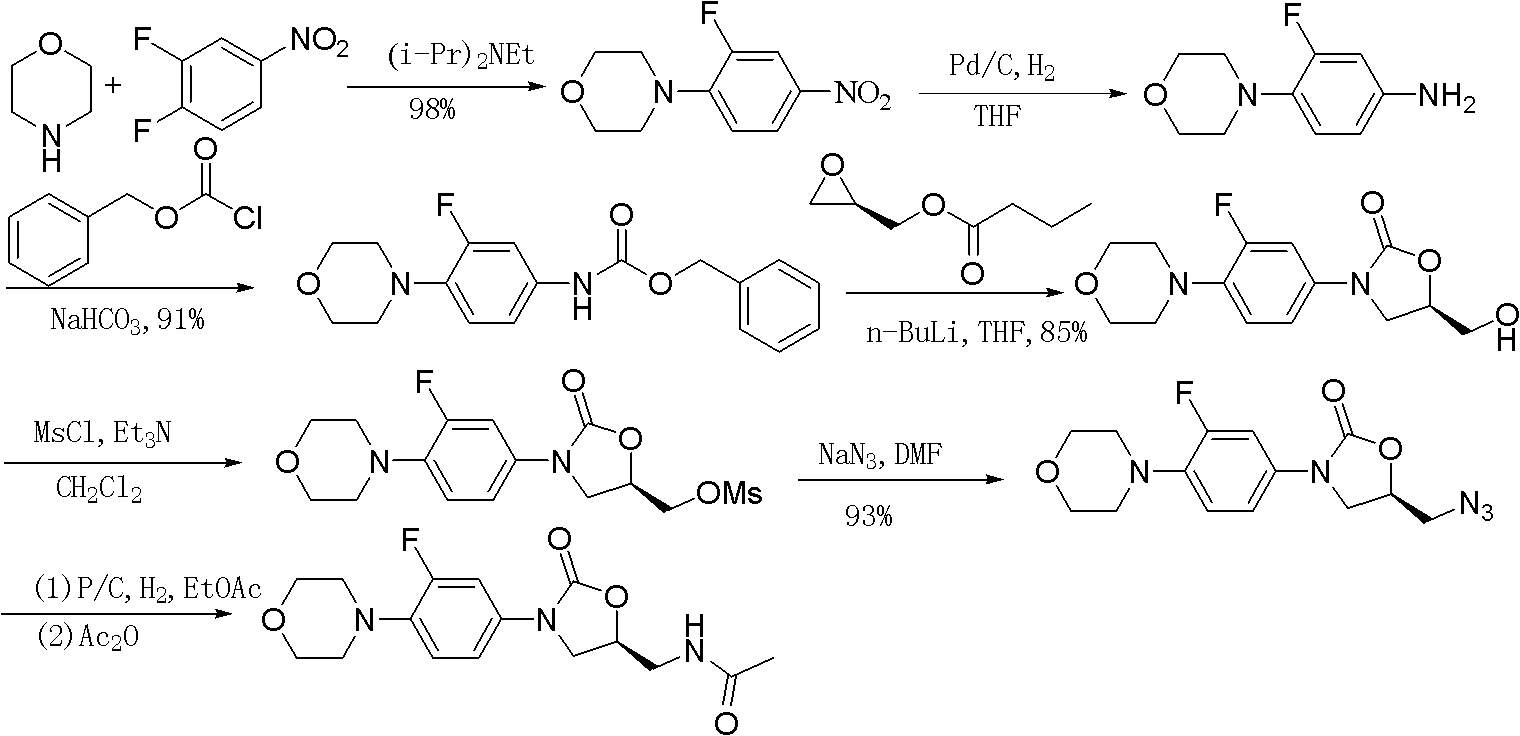

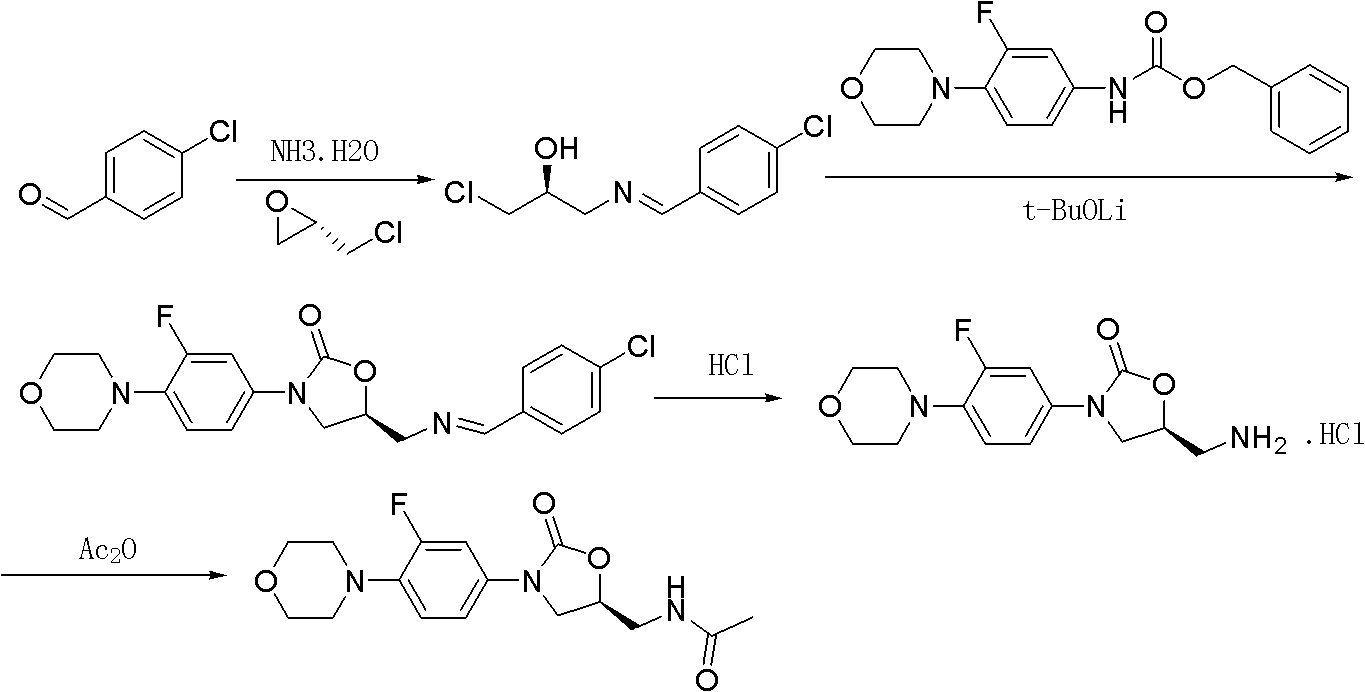

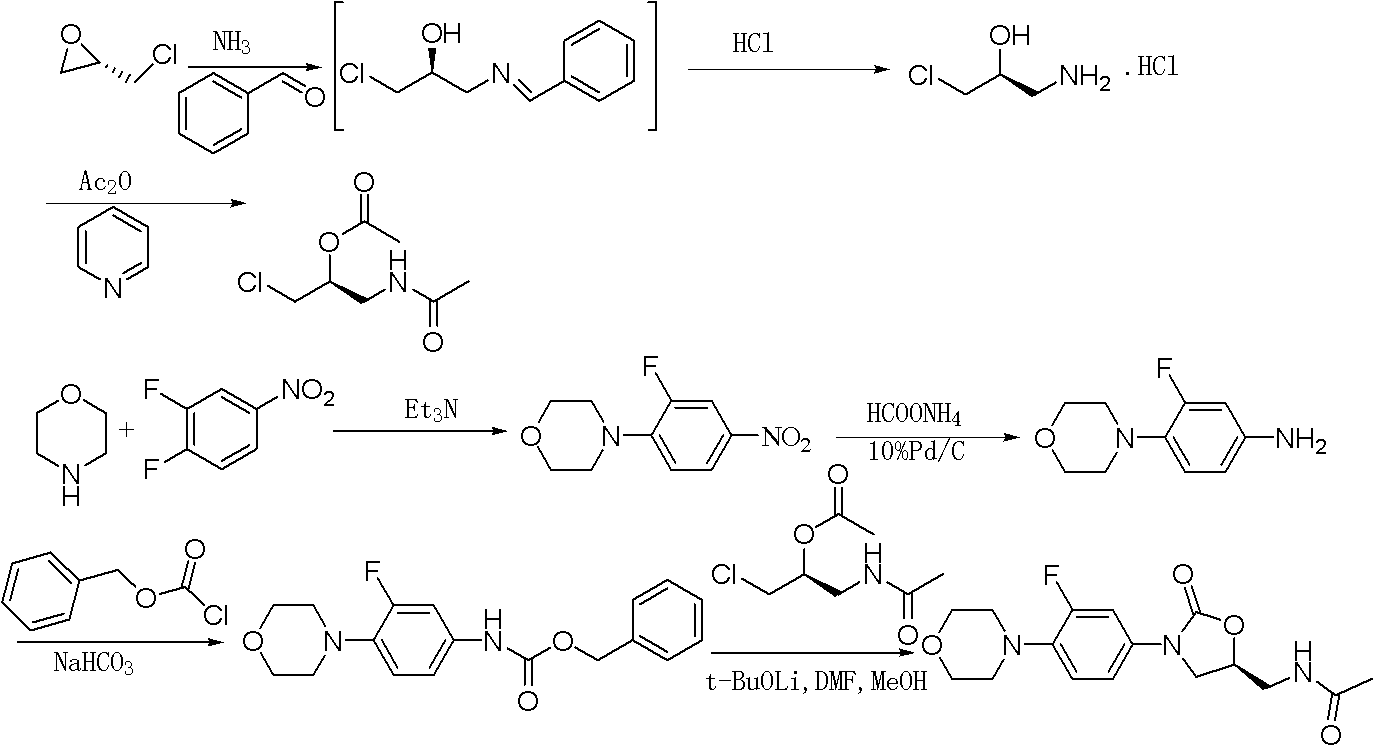

Method used

Image

Examples

Embodiment 1

[0048] Example 1. Preparation of S-1-azido-3-chloro-2-propanol:

[0049] Add S-epichlorohydrin (50g, 0.543mol) and ammonium chloride (14.5g, 0.272mol) into 200mL of ethanol and 50mL of water, stir for 5min, add sodium azide (37.1g, 0.571mol), and react at room temperature After 48 hours, distill off ethanol, add a large amount of water to dissolve the inorganic salt, extract with dichloromethane, distill off the yellow liquid S-1-azido-3-chloro-2-propanol (51.5 g, 70%).

Embodiment 2

[0050] Example 2. Preparation of 3-fluoro-4-morpholine nitrobenzene:

[0051] Morpholine (5.84mL, 0.066mol) and potassium carbonate (4.5g, 0.033mol) were added to 20mL of ethanol, and 3,4-difluoronitrobenzene (10g, 0.063mol) was added dropwise at room temperature. To reflux, the reaction was complete after 3 hours, the reaction was stopped, and a large amount of solids precipitated out at room temperature, which was added to 50 mL of water, stirred and filtered, and dried to obtain the product 3-fluoro-4-morpholine nitrobenzene (13.8 g, 97%).

Embodiment 3

[0052] The preparation of embodiment three.3-fluoro-4-morpholine aniline:

[0053] Add 3-fluoro-4-morpholine nitrobenzene (11.3 g, 0.05 mol) to a mixed solution of 23 mL of ethanol and 3 mL of water, then add ammonium chloride (1.34 g, 0.025 mol) and glacial acetic acid (1.15 mL, 0.01mol), stir and heat, add iron powder (14g, 0.25mol) in batches when the temperature reaches 70°C, reflux reaction for 3-4h after the addition is complete, the reaction is complete by TLC, stop the reaction, heat filter, filter cake with 12mL Ethanol was refluxed for 0.5h, then hot filtered, the ethanol solution was combined, activated carbon decolorized, most of the ethanol was evaporated, filtered, the filter cake was washed with a small amount of ethanol, and dried to obtain the product 3-fluoro-4-morpholineaniline (7.35g, 75 %).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com